Buffering oil cylinder

A buffer oil cylinder and buffer cylinder technology, applied in the field of hydraulic oil cylinders, can solve the problems of easy stuck valve core, insufficient reliability, and inability to reliably realize high-speed and heavy-load use occasions, and achieve good safety, reliability, and flexible structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

[0034] The front (front end) referred to in the present invention refers to an end that the piston rod protrudes, and the rear (rear end) is an end opposite to the front (front end).

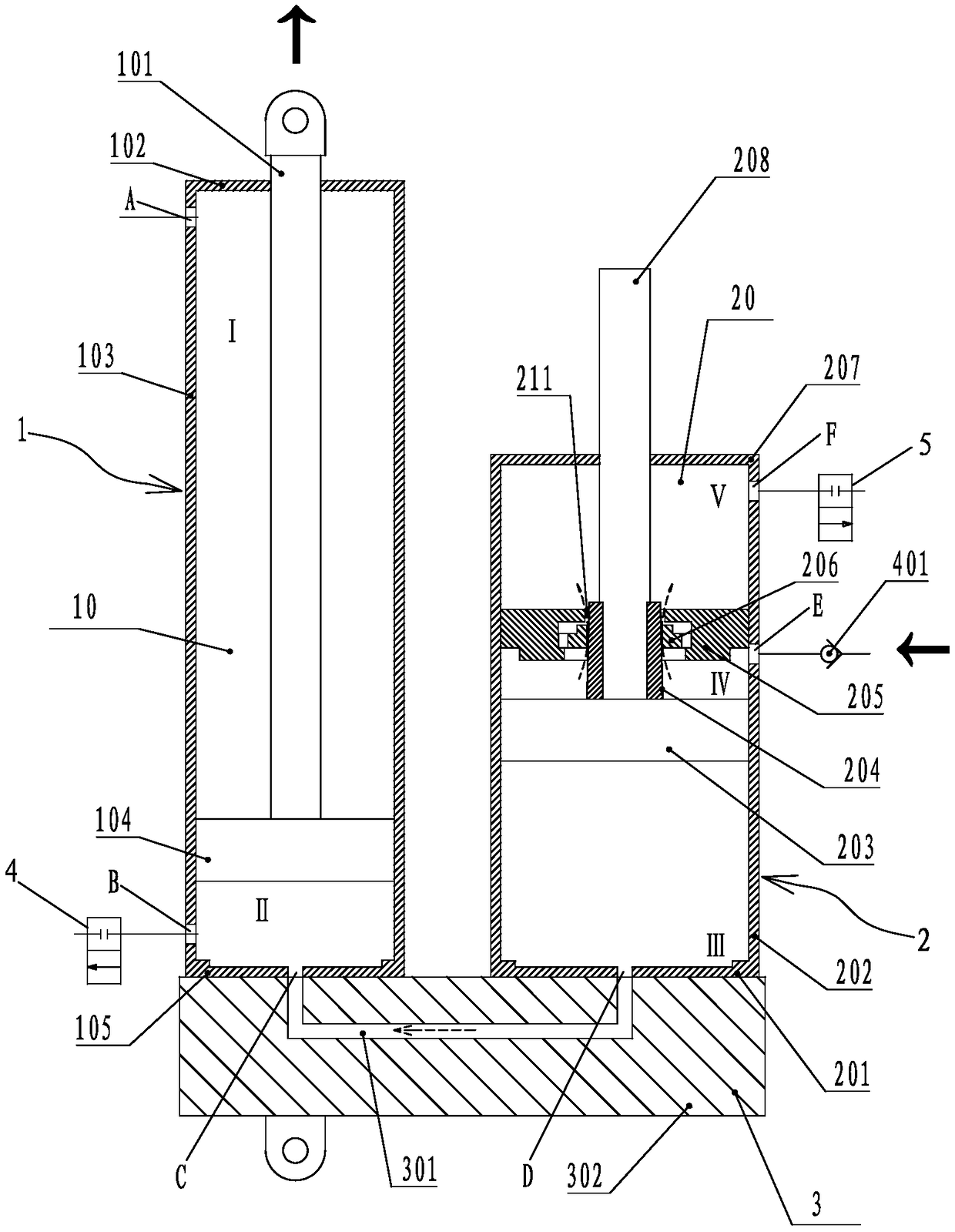

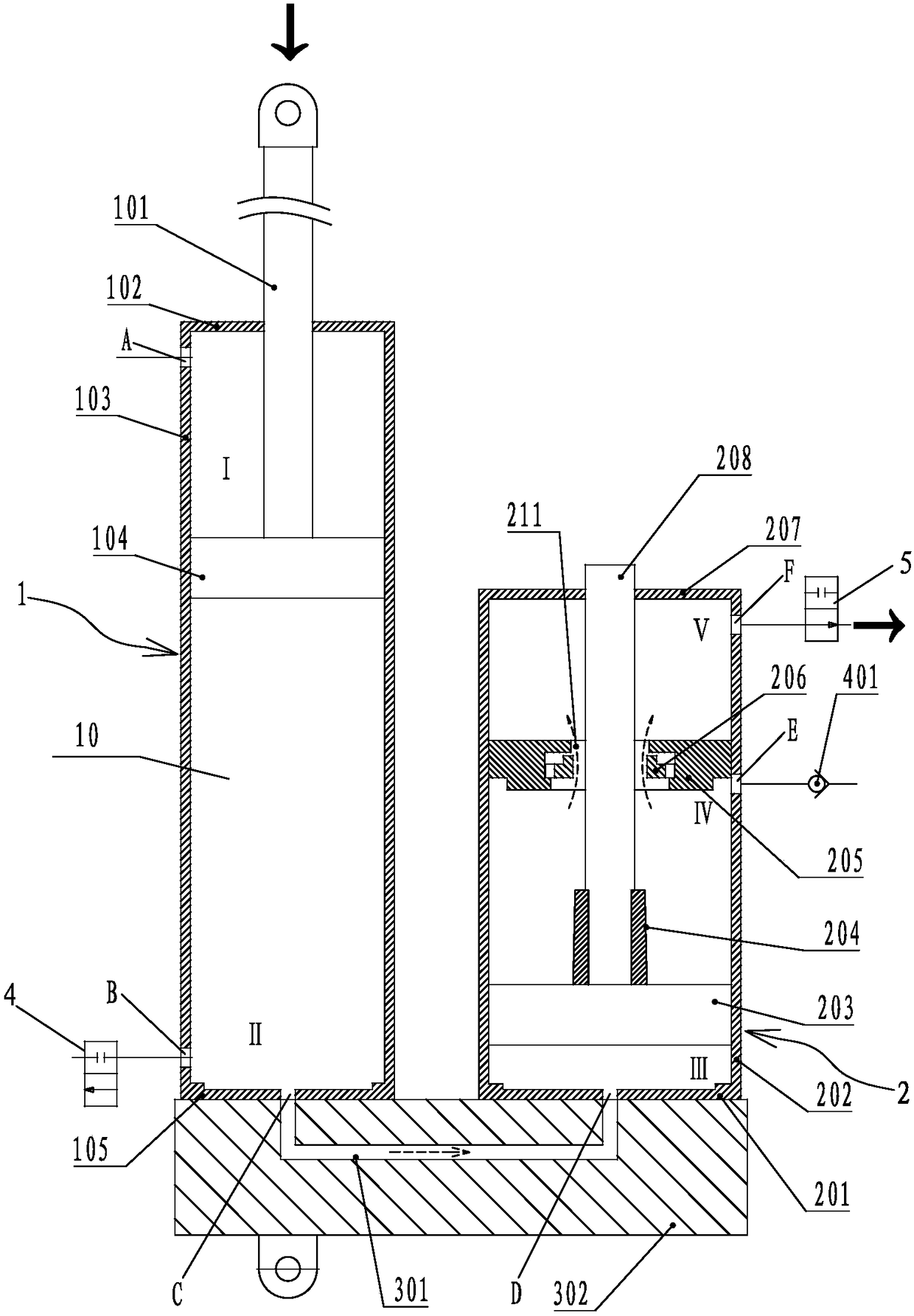

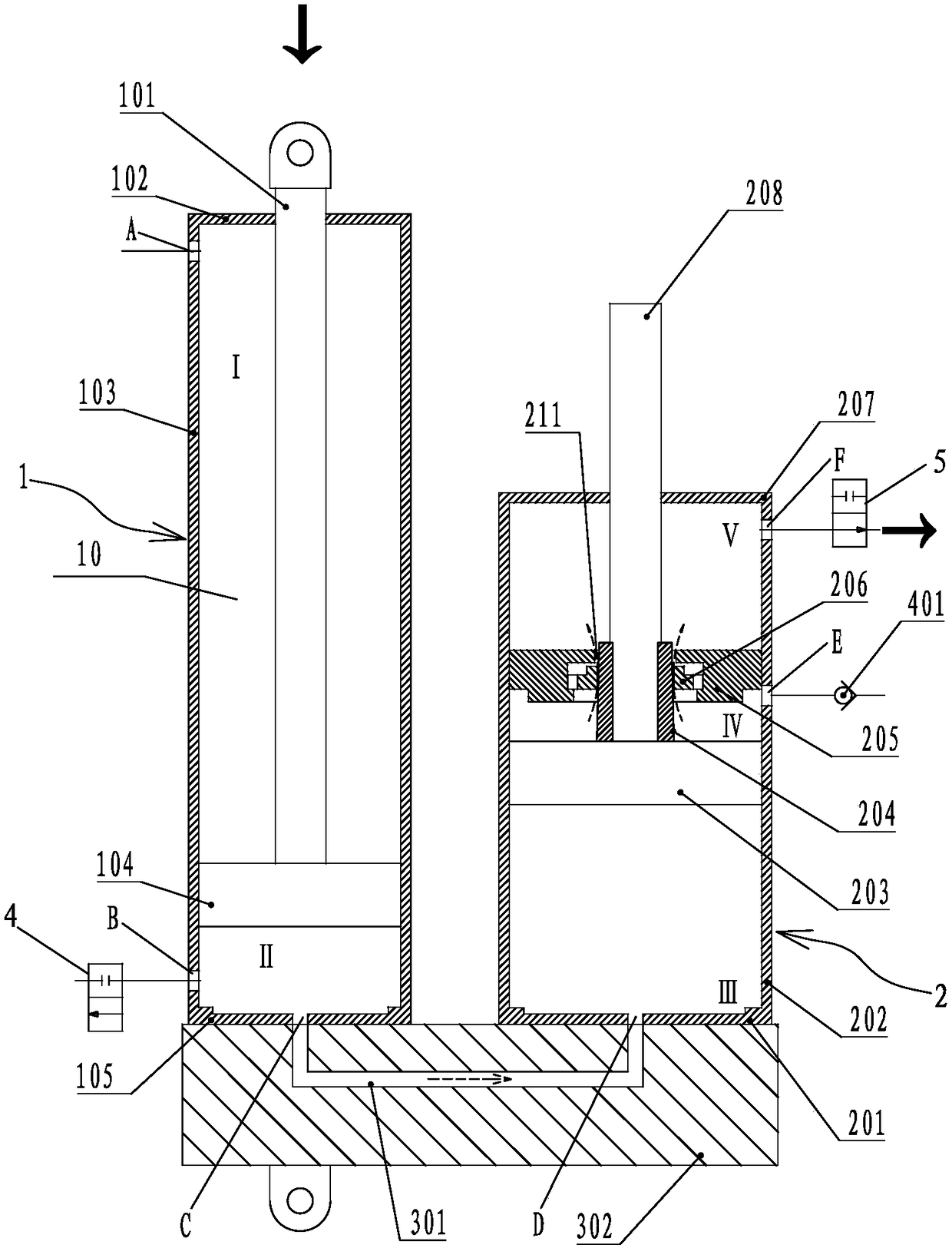

[0035] Such as Figure 1 to Figure 4 The shown buffer cylinder is an embodiment of one-way buffering in the present invention, including a power cylinder 1 and a buffer converter 2, the buffer converter 2 is independently arranged outside the power cylinder 1, and the power cylinder 1 includes The power cylinder block 10 made up of the front end cover 102, the power cylinder 103 and the rear end cover 105 is arranged at the center of the power cylinder 103 and passes through the power piston rod 101 of the front end cover 102 and is connected with the power piston rod 101 and connected with the power cylinder 101. The power piston 104 matched with the inner cavity of the cylinder 103, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com