OFDR technology based steel bar corrosion deformation monitoring system and using method thereof

A steel bar corrosion and deformation monitoring technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low measurement accuracy of instruments, low survival rate of measurement points, information feedback lag, etc., and achieve high sensitivity and spatial resolution, The effect of high sensitivity and spatial resolution and comprehensive data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

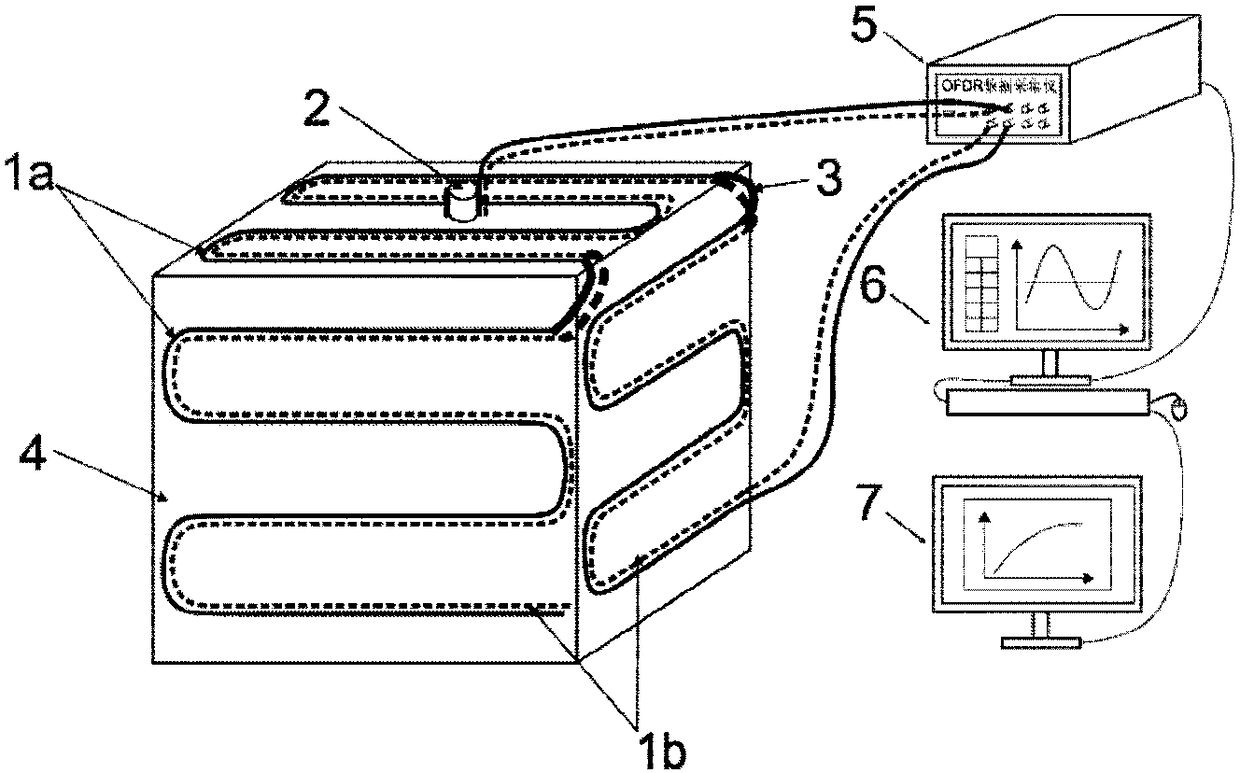

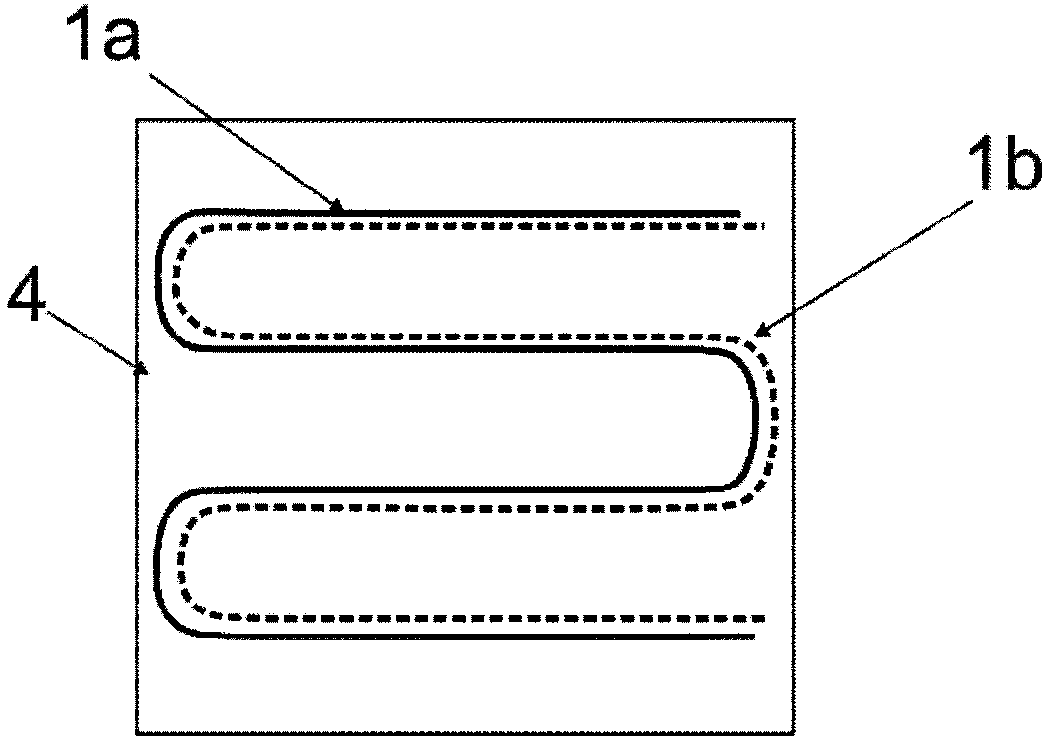

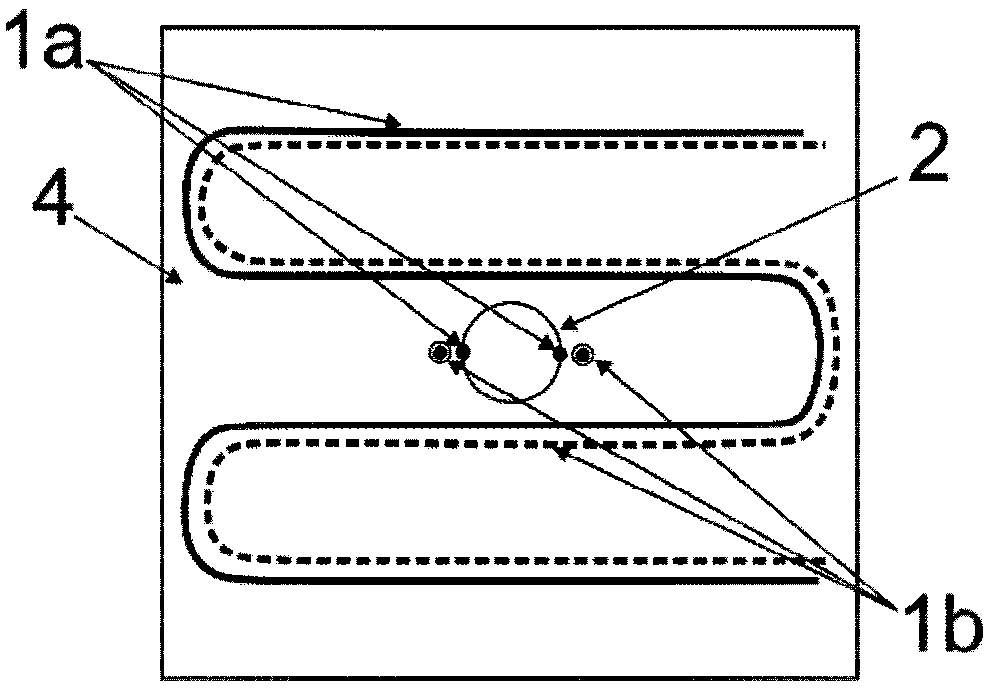

[0026] like figure 1 As shown, 1a is the strain sensing fiber, and 1b is the temperature compensation fiber, which are evenly arranged on the side and upper surface of the test block in an S-shape. When laying, the sensing fiber should be close to the surface of the test block. The strain-sensing optical fiber 1a is pre-stretched and laid in the pre-carved groove on the surface of the steel bar 2, and the temperature-compensating optical fiber 1b is placed naturally without applying force. A certain length should be reserved at the beginning of the laid sensing optical fiber, so that it can be led out and connected to the data acquisition instrument in the later test, and the optical fiber connection is reinforced and protected with a thermal expansion tube. 2 is the steel bar; 3 is the armored sheath, which protects the bending of the optical fiber; 4 is the 1m x 1m x 1m concrete test block, which is used as the carrier of the corrosion of the steel bar; 5 is the optical fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com