Soil Sampler

A soil sample and control panel technology, which is applied in the preparation, sampling, and instrumentation of test samples, can solve the problems of low cutting precision, uneven size, and poor uniformity, and achieve convenient operation, simple control methods, and easy-to-use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

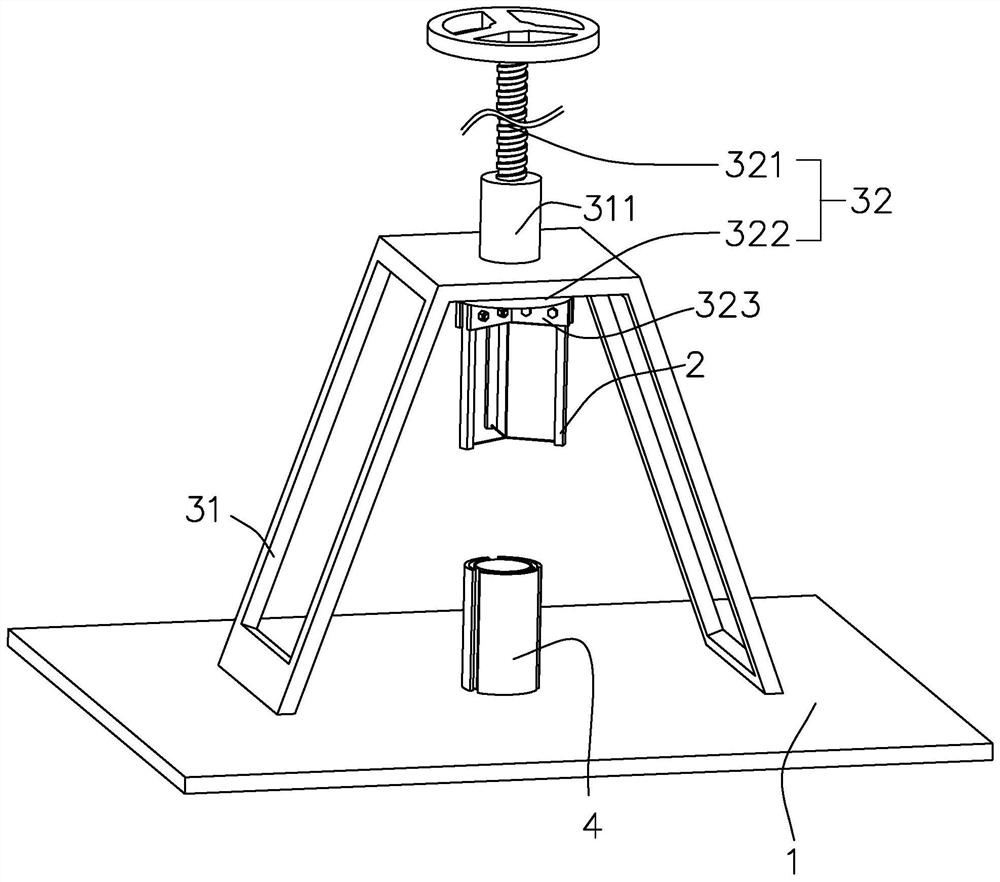

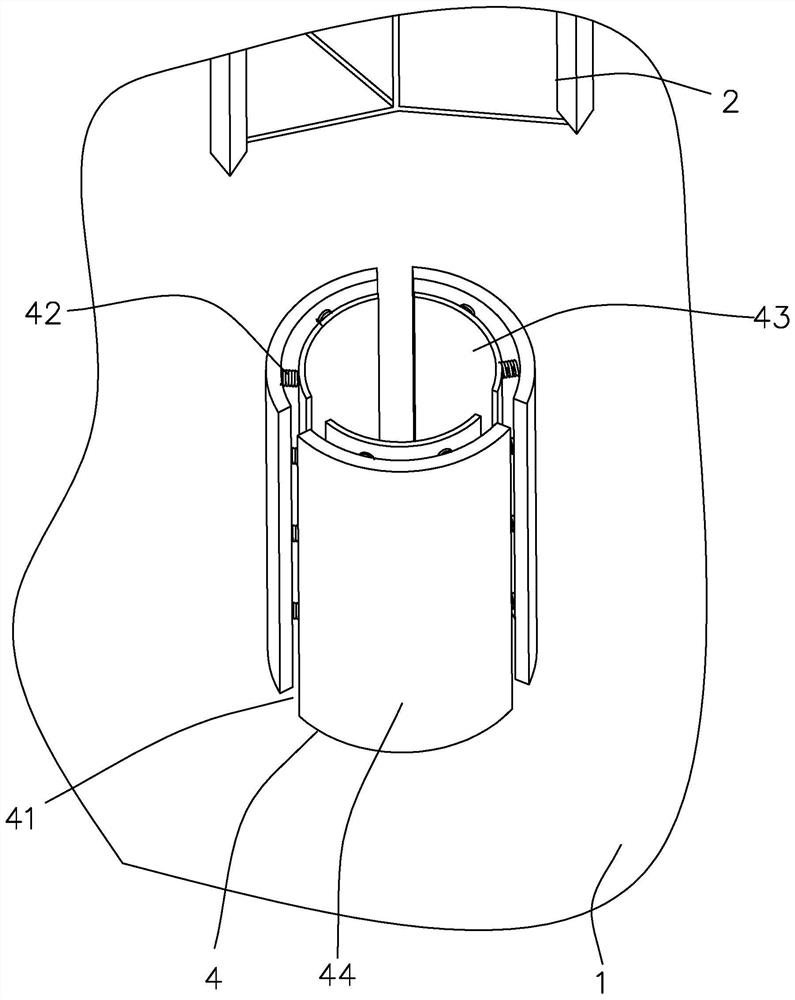

[0040] A soil sample preparation device, such as figure 2 , including a base 1, a wire saw 2 and a control mechanism. There are three wire saws 2 which are movably connected to the base 1 , and the control mechanism controls the movement of the wire saws 2 . The control mechanism controls the wire saws 2 to perform linear motion, the angle between two adjacent wire saws 2 is 120°, and the three wire saws 2 divide the circumference into equal parts to ensure the uniformity of the cut soil samples. The length of the wire saw 2 is greater than the height of the columnar soil, so as to ensure the cutting effect of the wire saw 2 on the columnar soil and ensure the cutting quality.

[0041] Such as figure 2 , The base 1 is provided with a limit cylinder 4 for limiting the position of the columnar soil, and the limit cylinder 4 cooperates with three wire saws 2 . The columnar soil is placed in the limiting cylinder 4, and the three wire saws 2 cut the columnar soil. When the th...

Embodiment 2

[0051] The difference between embodiment two and embodiment one is that the control mechanism is different: as Figure 5 and Figure 6 , the control mechanism includes a control coil wire 33 , a sliding block 34 and a control handle 35 . The control wire 33 is rotatably connected to the bottom of the base 1 , and the control wire 33 and the limit cylinder 4 are arranged coaxially. The sliding block 34 and the control handle 35 are connected with the control wire 33 .

[0052] Such as Figure 6 The lower surface of the control coil wire 33 is provided with a rotating tooth groove 332, the control handle 35 is rotatably connected to the bottom of the control coil wire 33, and the end of the control handle 35 is provided with a rotating gear 351 meshing with the rotating tooth groove 332. The axis of the control wire 33 is perpendicular to the axis of the rotating gear 351 . The operator rotates the control handle 35, and the control handle 35 drives the control coil wire 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com