Equipment for producing novel material

A new energy and passenger car technology, applied in the field of material processing, can solve the problems of potential safety hazards, no protective cover, and inability to cut, etc., to achieve the effects of improving safety, avoiding sputtering and hurting people, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

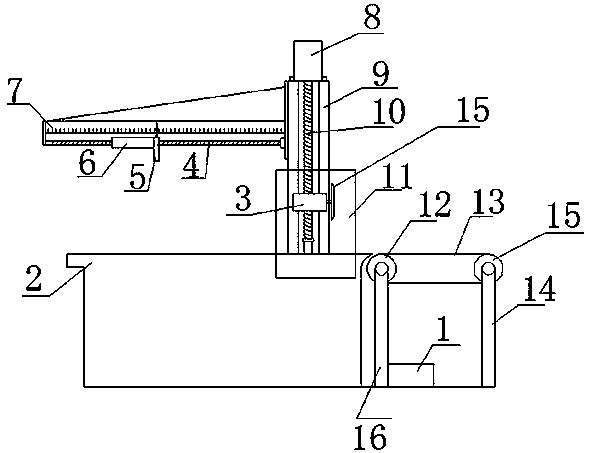

[0016] Such as figure 1 As shown, a device for producing new materials, servo motor a1, cutting table 2, motor 3, screw rod a4, scale 7, servo motor b8, support column 9, screw rod b10, baffle plate 11 and conveyor belt 13 , the right side of the cutting table 2 is provided with a transmission device consisting of a driving wheel 12, a driven wheel 15, a conveyor belt 13, a support frame a16 and a support frame b14, a servo motor a1 is provided on the right side of the bottom of the support frame a16, and the top of the support column a16 A drive wheel 12 is provided, a support frame b14 is provided on the right side of the support frame a16, a driven wheel 15 is provided on the top of the support frame b14, a conveyor belt 13 is provided between the driven wheel 15 and the drive wheel 12, and the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com