LED half-bridge circuit with feedback variable-frequency constant-current driving

A half-bridge circuit and constant-current drive technology, applied in the field of LED half-bridge circuit with feedback variable frequency constant current drive, LED drive circuit, can solve the problem of direct control port without output current, unfavorable heat dissipation of chip peripheral circuit, high current and high power It can reduce the temperature, reduce the power consumption and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

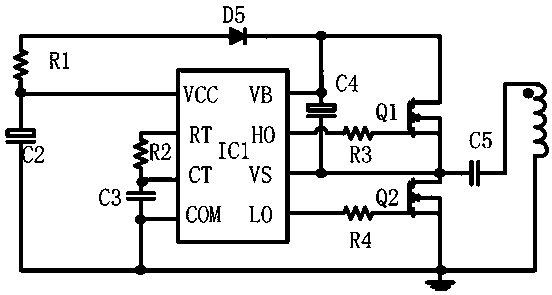

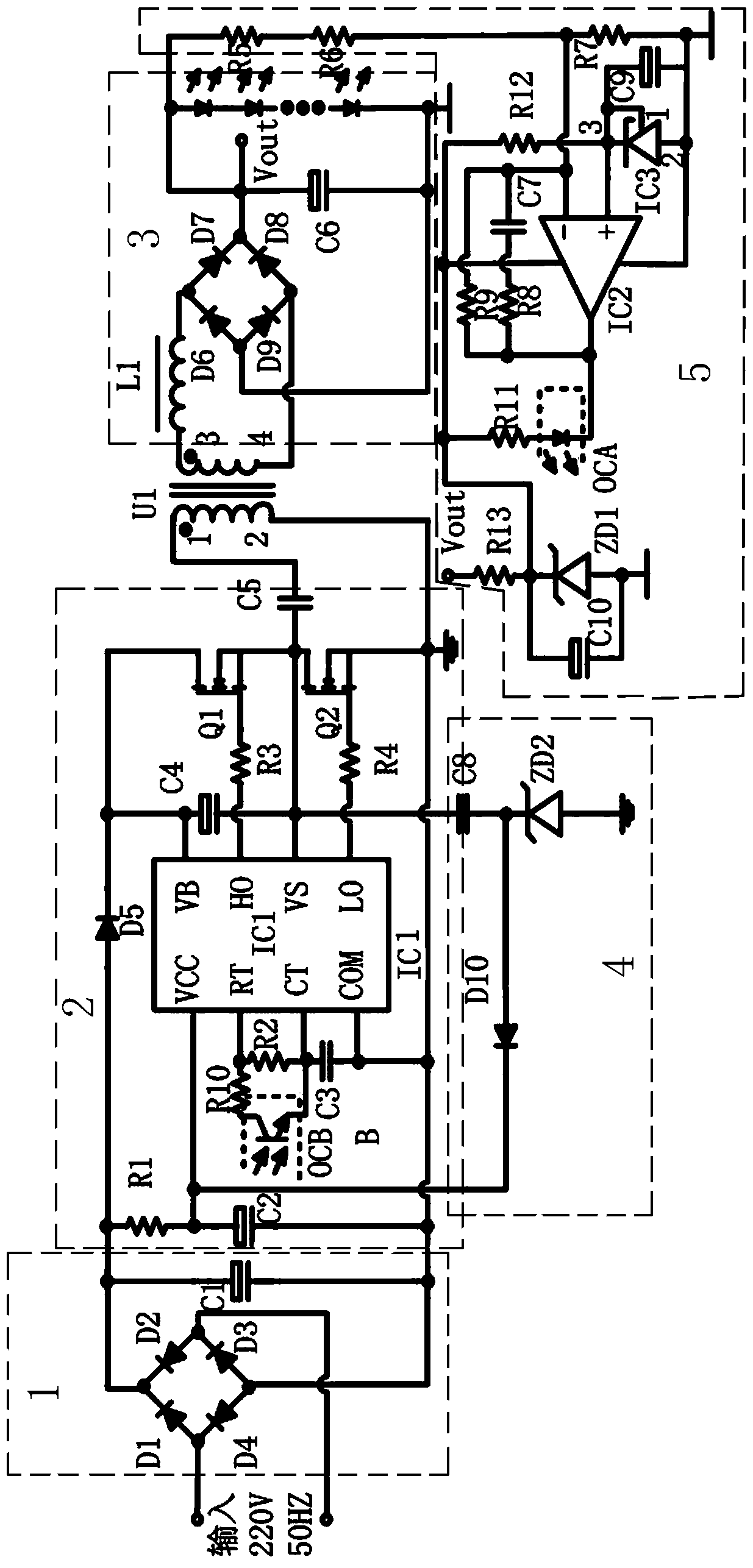

[0027] Embodiment An LED half-bridge circuit with feedback variable frequency constant current drive

[0028] Such as figure 2 As shown, it includes input rectification and filtering circuit 1, half-bridge control circuit 2, isolation transformer U1, output rectification and filtering circuit 3 connected in series, and also includes a control chip for charging the electrolytic capacitor connected to the power port of half-bridge control circuit 2. Circuit 4, a feedback circuit for regulating output current stability, the input end of the control chip power supply circuit 4 is connected to the half-bridge midpoint of the half-bridge control circuit 2, and the output end is connected to the power supply end of the half-bridge control circuit 2; the feedback The input end of the circuit is connected to the positive electrode of the output load of the output rectification filter circuit, the output end is the primary side of the first photocoupler, and the output is connected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com