Channel type absorbing body

An absorber, channel-type technology, applied in medical science, bandages, etc., can solve the problems of poor diffusion efficiency of the absorber and uncomfortable wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

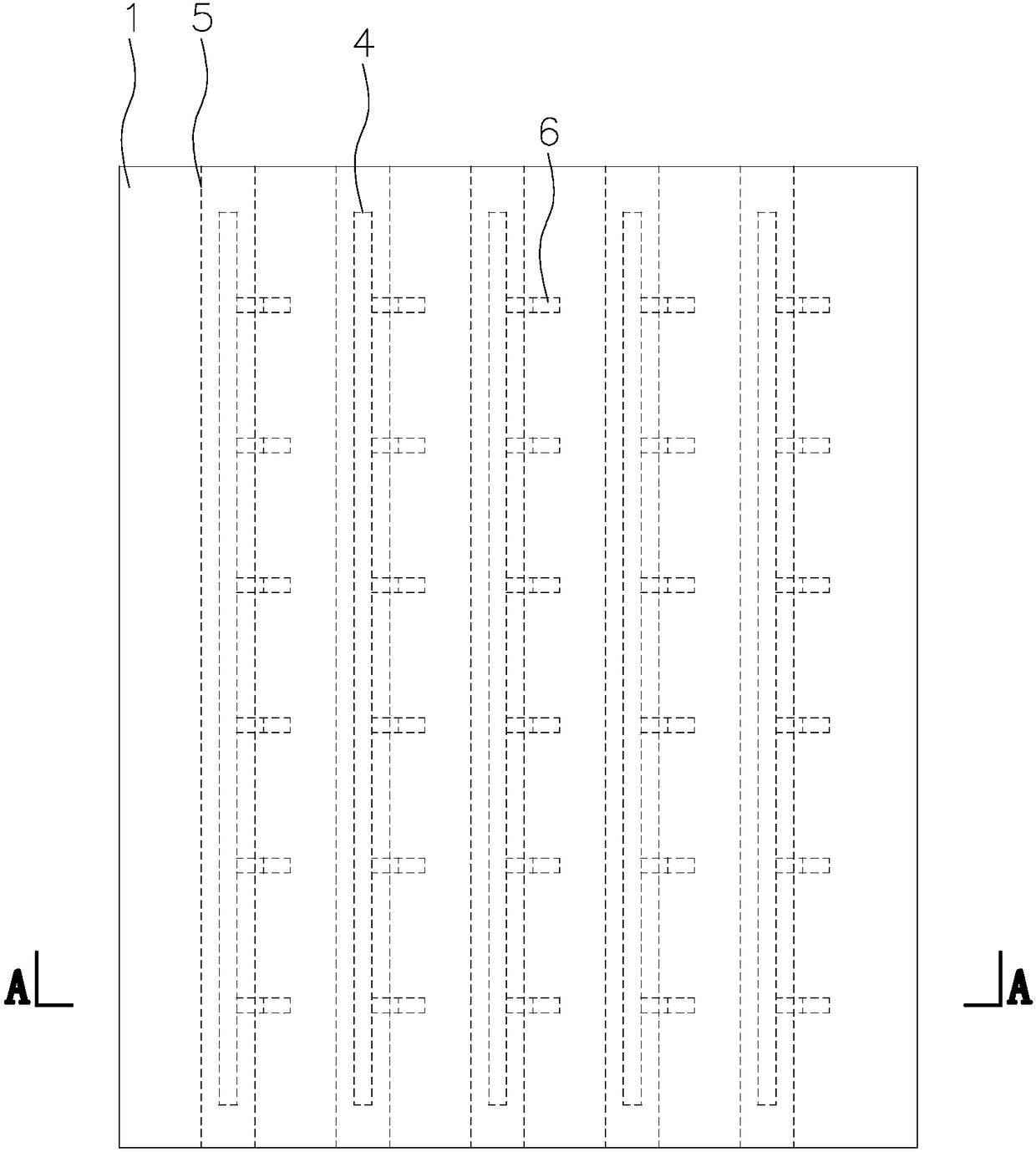

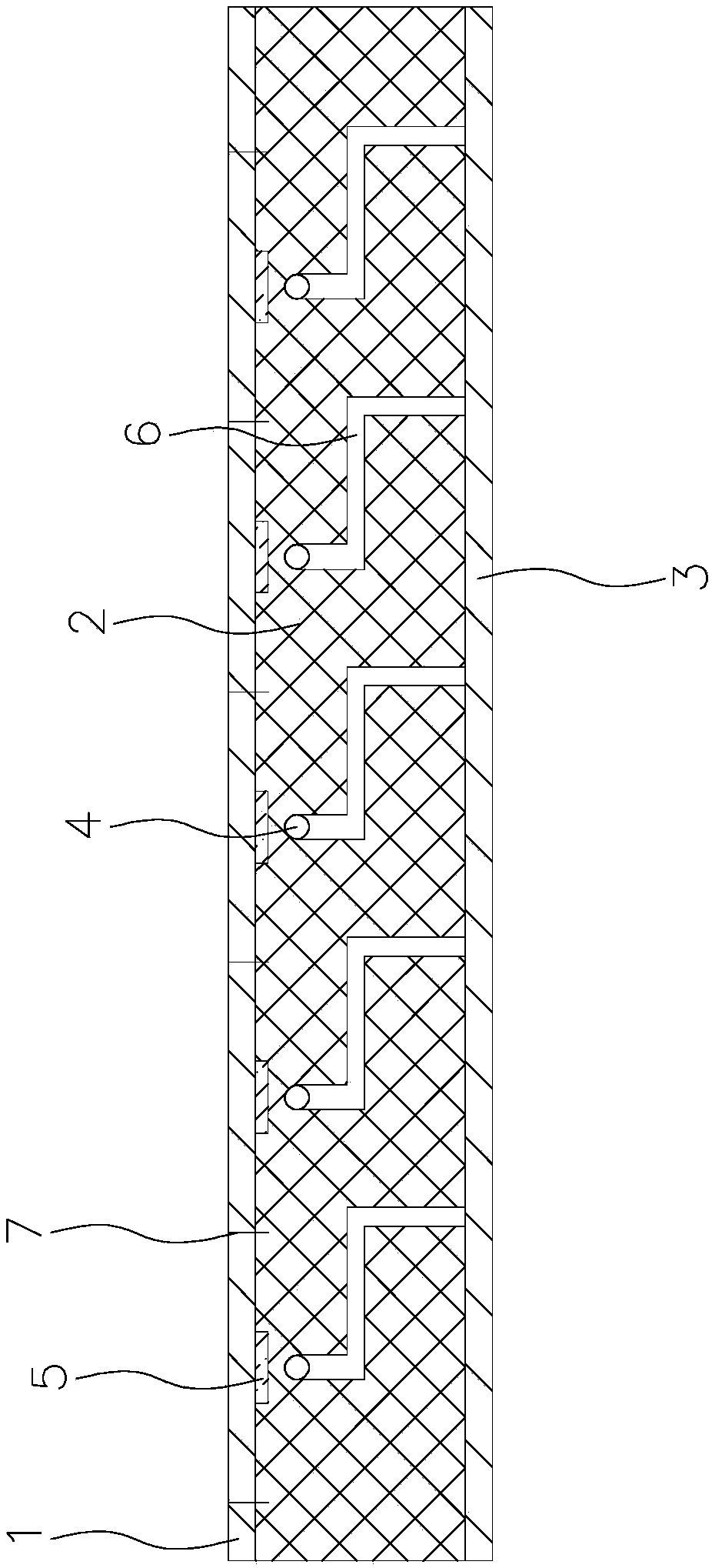

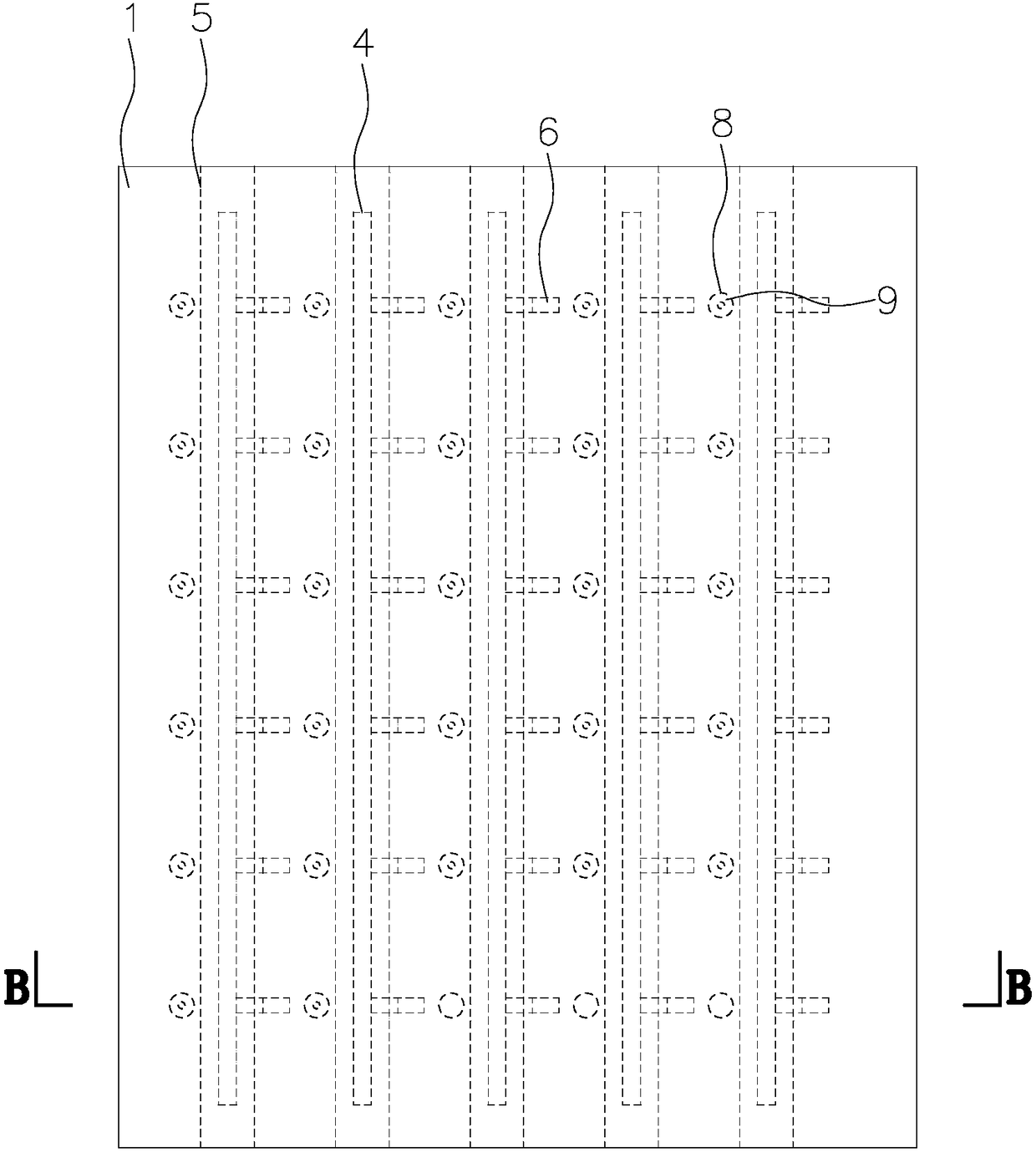

[0014] refer to figure 1 , figure 2 , the present embodiment 1 provides a channel type absorber, comprising an upper layer non-woven fabric 1, a lower layer non-woven fabric 2 and an absorbent core 3 arranged between the upper layer non-woven fabric 1 and the lower layer non-woven fabric 2, the absorbent core 3 is embedded with a plurality of water-absorbent resin strips 4 extending along the length direction, and the upper surface of the absorbent core 3 is provided with a water-impermeable film 5 above each water-absorbent resin strip 4, and each water-absorbent resin strip 4 is provided with a plurality of water-absorbent resin strips. The side-folded guide water-absorbent resin strip 6, the upper non-woven fabric 1 and the absorbent core 3 form a bonding part 7 between two adjacent water-impermeable films 5 by hot-melt bonding. The free end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com