Spraying pressing device and method for excess waste glass fiber material

A technology of residual material and spray pipe, applied in the direction of spray device, liquid spray device, device for coating liquid on the surface, etc., can solve the problems of difficult to grasp the dry humidity, high labor intensity of workers, poor penetration effect, etc. The effect of improving production efficiency and product quality, reducing labor intensity and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

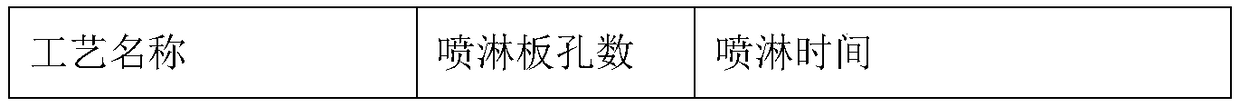

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0025] The invention provides a device and method for spraying and drying waste glass fiber surplus materials. Press dry to achieve more thorough infiltration of glass fiber residue, proper press dry, improve product quality, reduce labor intensity, and increase production efficiency.

[0026] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

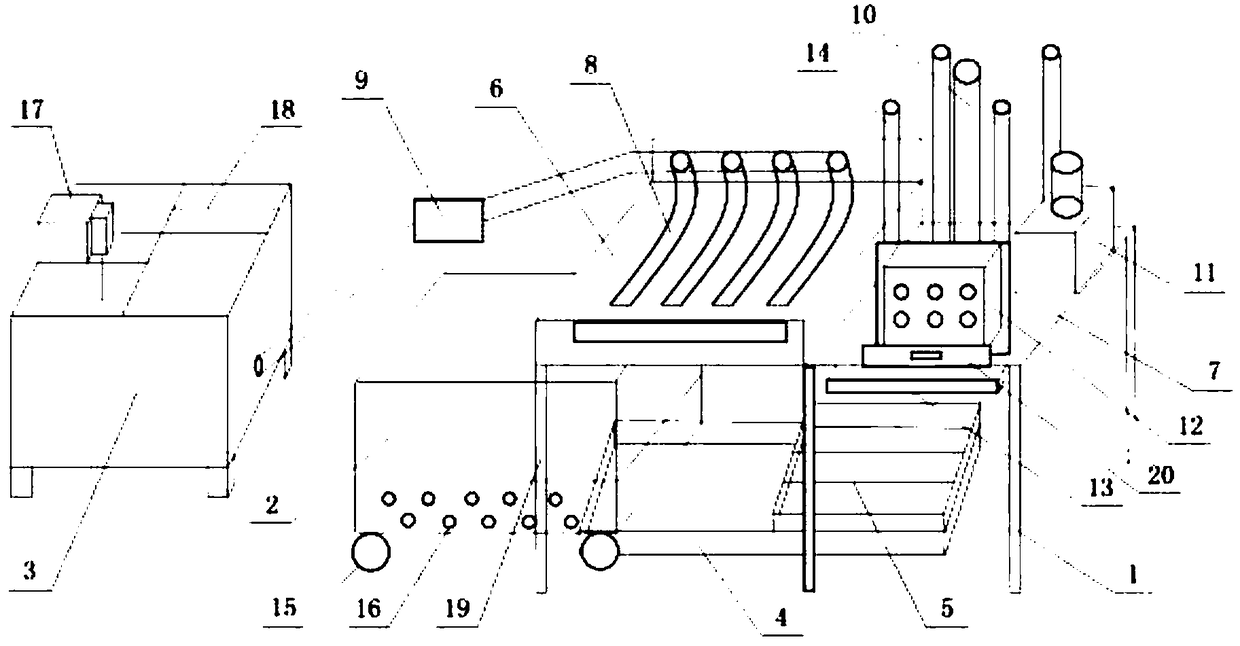

[0027] Such as figure 1 As shown, a device for spraying and drying waste glass fiber residues, said device includes: a spray press 1, a material cart 2 and a liquid medicine pool 3;

[0028] The spray press 1 includes: a frame 19, the bottom of the frame 19 is provided with a liquid medicine recovery tank 4 for recovering liquid medicine, and the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com