Manufacturing equipment of exhaust pipe for heavy-duty vehicle

A technology for manufacturing equipment and exhaust pipes, applied in vehicle parts, transportation and packaging, etc., can solve the problems of flat exhaust pipes and reduce the quality of exhaust pipe products, to avoid waste, better quality of elbows, and better operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

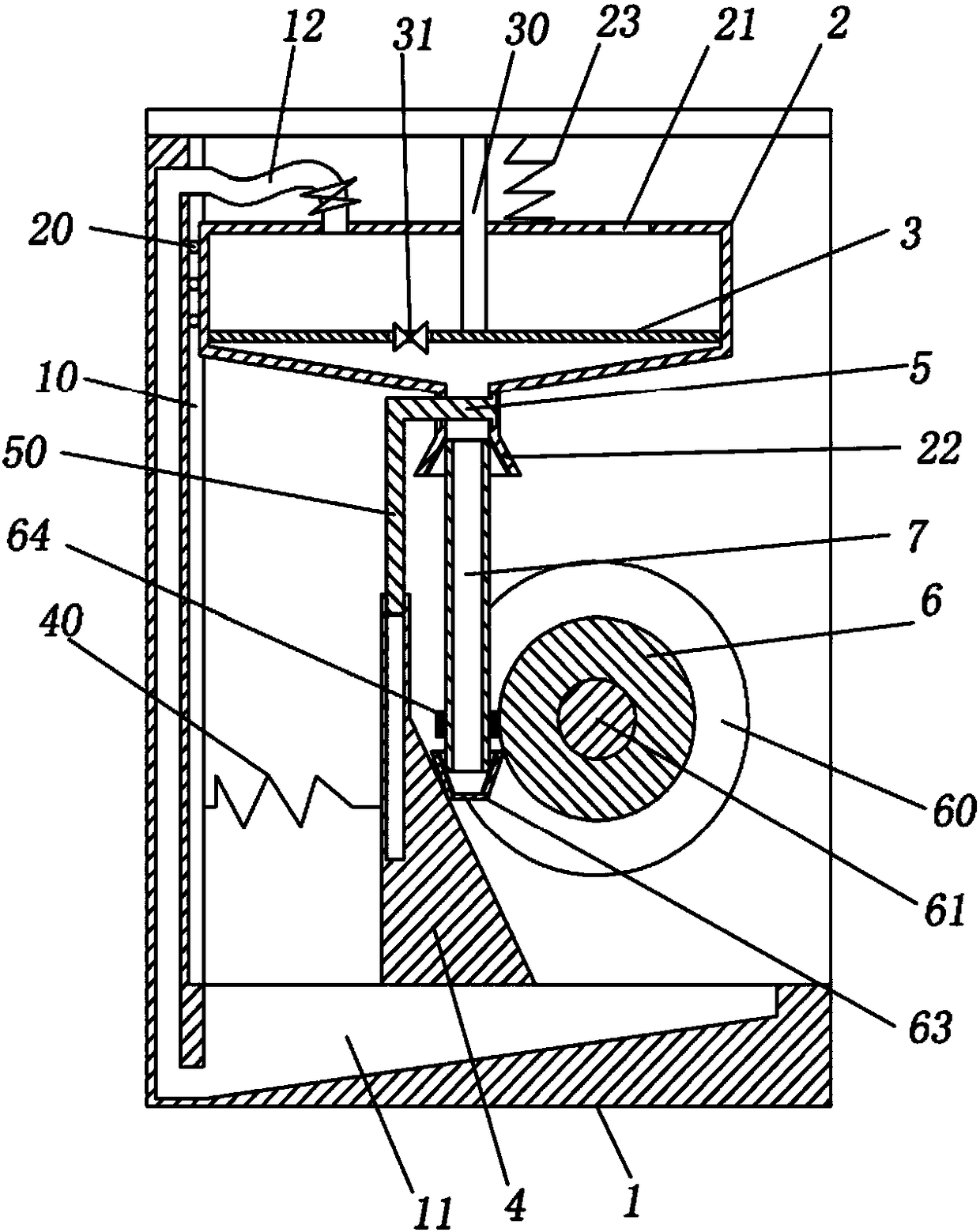

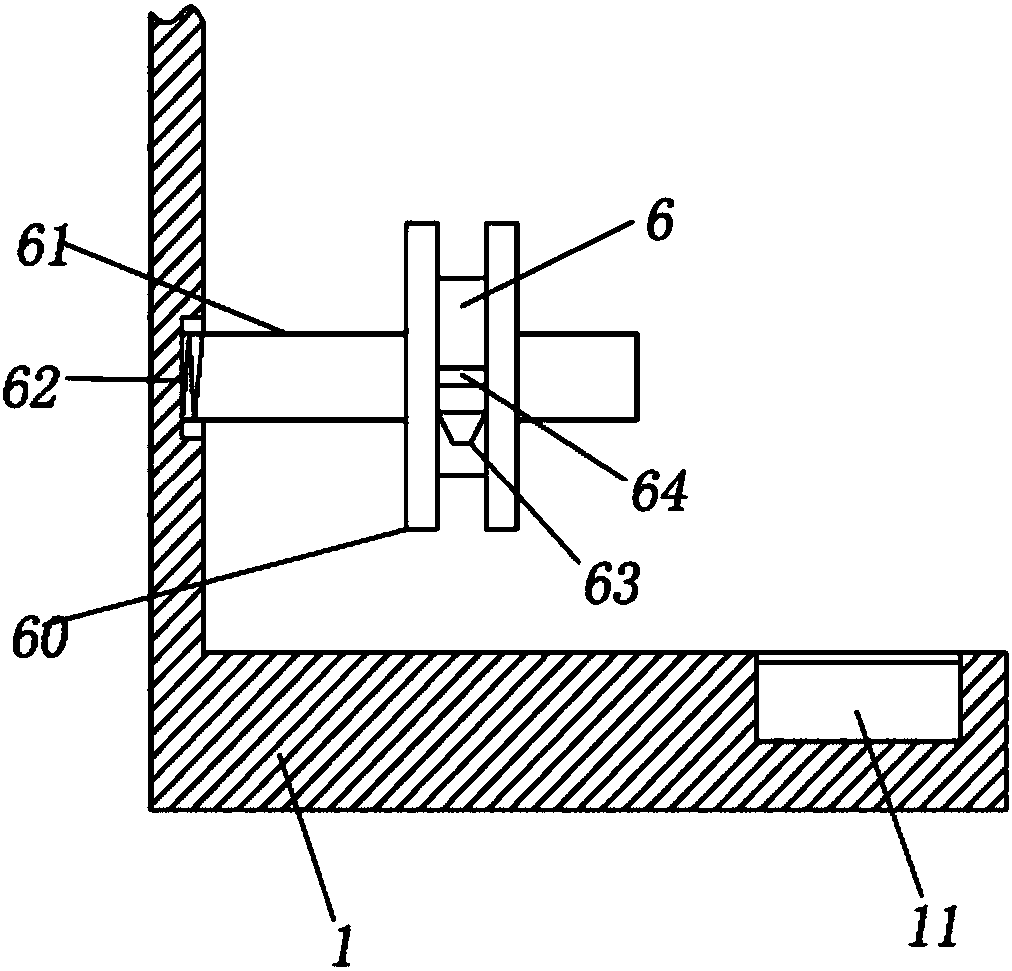

[0019] The reference signs in the drawings of the description include: frame 1, slide rail 10, sand collection tank 11, hose 12, sand box 2, roller 20, sand inlet 21, sand discharge outlet 22, tension spring 23, piston 3 , fixed rod 30, sand outlet 31, wedge 4, compression spring 40, opening and closing door 5, slide bar 50, center plate 6, protection plate 60, rotating shaft 61, torsion spring 62, fixing groove 63, fixing ring 64, exhaust pipe7.

[0020] The embodiment is basically as figure 1 Shown: The manufacturing equipment of exhaust pipes for heavy vehicles, including frame 1, sandbox 2, wedges 4 and disc molds for bending exhaust pipes 7.

[0021] The sandbox 2 is slidingly connected with the frame 1, and the specific sliding connection method is preferred: slide rails 10 are provided on the side wall of the frame 1, rollers 20 are installed on the sandbox 2, and the rollers 20 are slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com