Z-shaped welding line stirring friction welding process method

A welding process and friction stir technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems affecting the engineering application of friction stir welding technology, achieve good welding accessibility, ensure welding quality, and increase economic costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

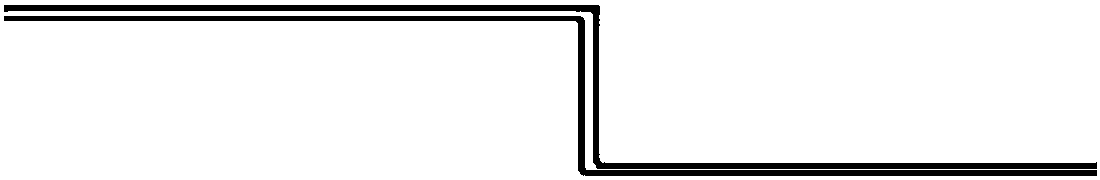

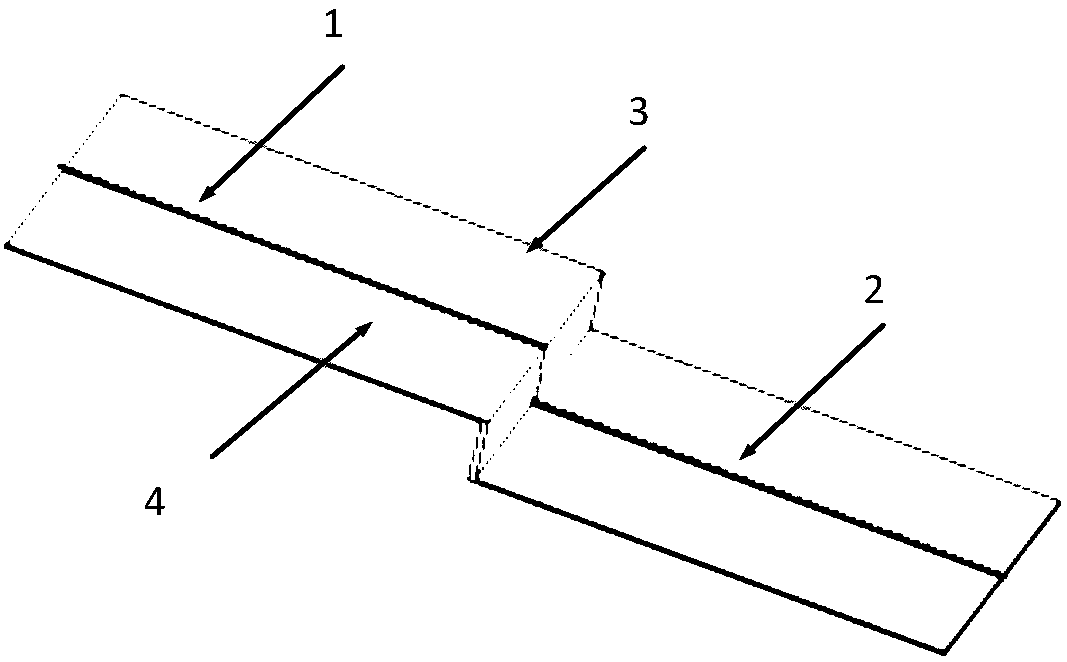

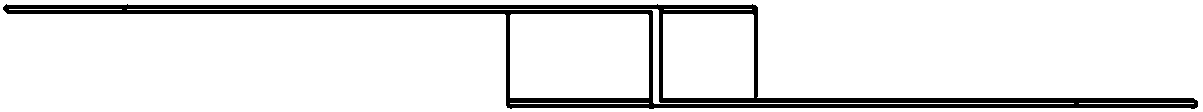

[0040] The present invention will be described in further detail below in conjunction with accompanying drawing, please refer to Figure 1 to Figure 9

[0041] Step 1. Increase welding process allowance

[0042] When the parts are being processed, add welding process margins 5, 6, 7 and 8 at both ends of the weld along the weld direction of the upper weld 1 and the lower weld 2 respectively, and change the Z-shaped weld into a "work" "Font weld. The thickness of the welding seam is the same as that of the welding seam where the welding process allowance is located. Its structural shape can be determined according to the specific conditions of the part. Its structural shape can be "one" shape, L shape, Z shape, T shape, I shape, etc. Or the extension of the end face of the part.

[0043] Step 2. Welding

[0044] The present invention provides two kinds of welding sequences, the starting and receiving points of welding seam are A point, B point, C point, D point, E point and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com