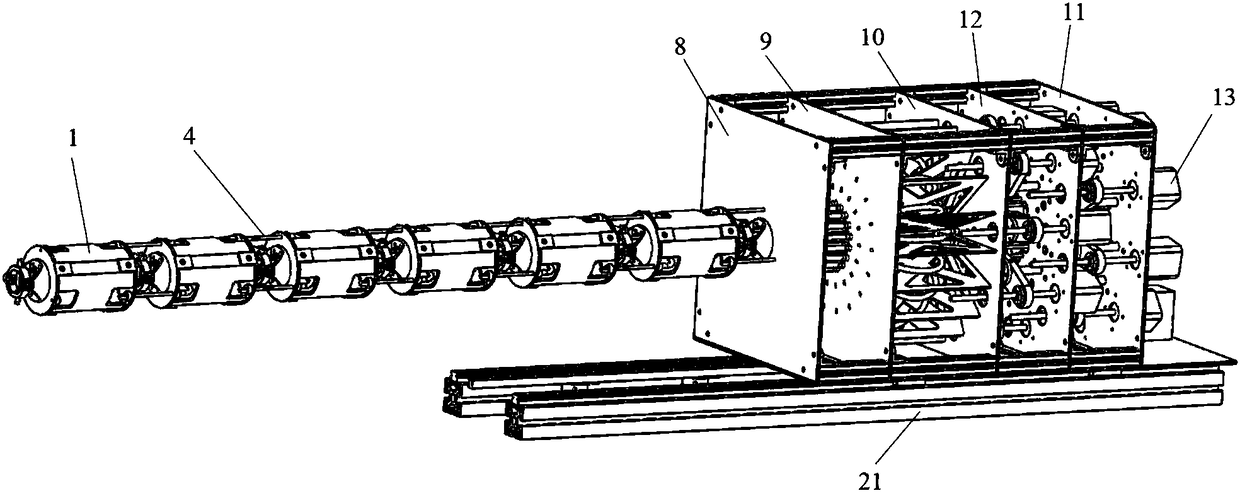

Multi-joint mechanical arm

A multi-joint robotic arm and robotic arm technology, applied in the field of robotic arms, can solve the problems of small number of joints, large volume, and only specific work, and achieve the effect of large flexibility, small size, and large degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

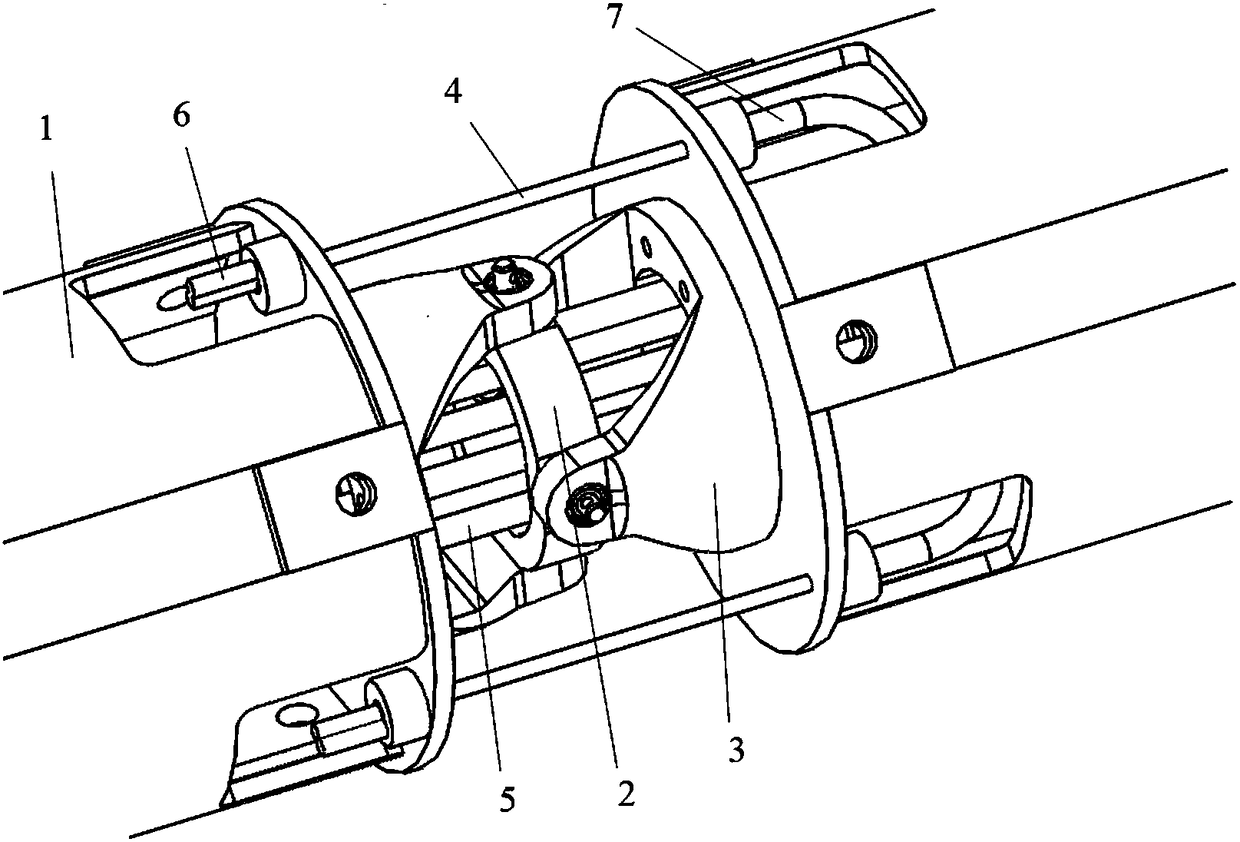

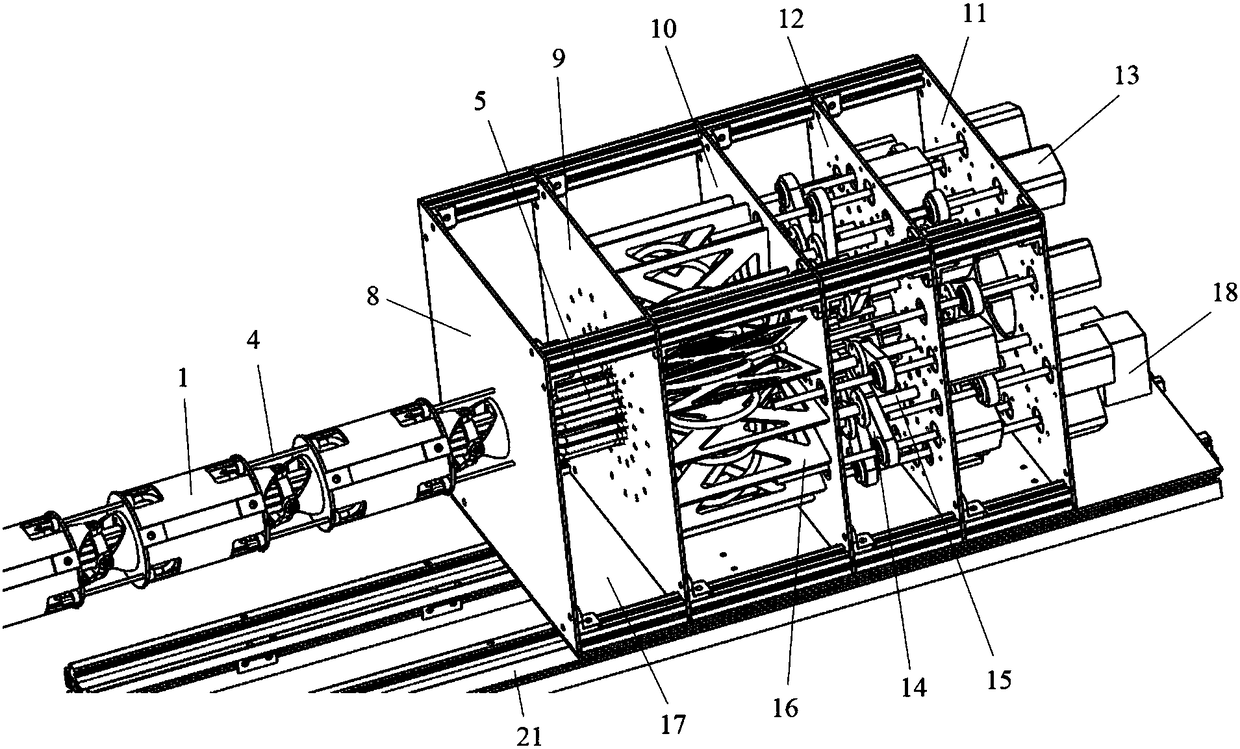

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

[0031] Although traditional industrial robotic arms, such as the robotic arms developed and produced by FANUC, KUKA, ABB, and Kawasaki, have played a huge role in promoting the intelligent development of today's factories, reducing labor costs and improving production efficiency, but The disadvantage of this type of traditional robotic arm is that it requires specific production or programming, and only specific working conditions, so that in some cases where it is necessary to enter a small space, these specific robotic arms are useless. For example, in the highly sophisticated and lightweigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com