Piling device and method

A technology of piling device and pile hammer, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of difficult adjustment of piling force and hydraulic hammer piling control, poor reliability of the device, large environmental pollution, etc., and achieve frequency and stroke Easy to control, long piling stroke, strong expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

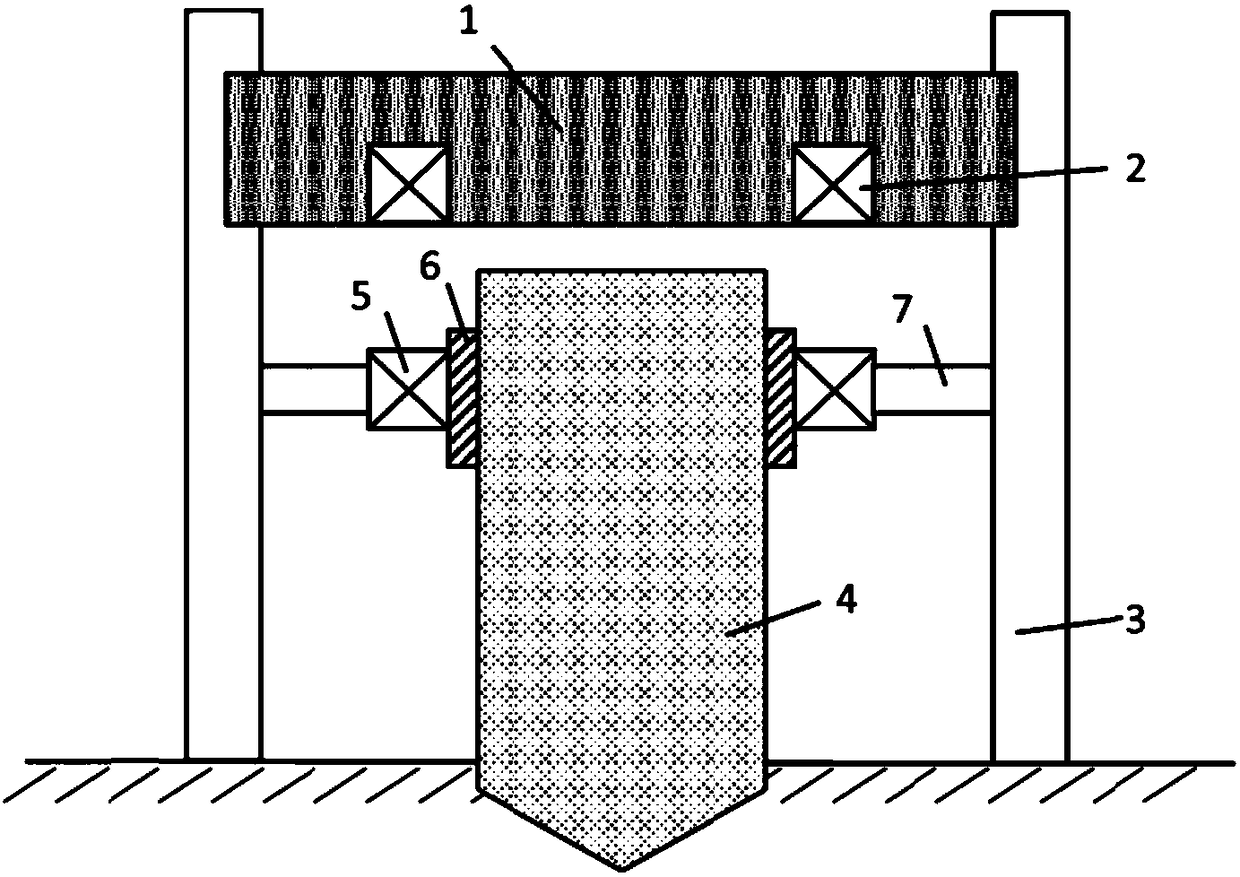

[0042] Such as figure 1 As shown, the overall structure of the piling device according to the embodiment of the present invention includes: a pile hammer 1 , a pile hammer coil 2 , a pile frame 3 , a pile body 4 , a pile body coil 5 , a clamping part 6 , and a beam 7 .

[0043]The pile frame 3 is set on the ground to provide support for the pile hammer 1 and the pile clamping mechanism, and has a guide rail structure; the pile hammer 1 is installed on the pile frame 3, and the pile hammer 1 can move freely on the pile frame 3; the pile hammer coil 2 is fixed on On the pile hammer 1; the pile clamping mechanism includes a clamping part 6 and a beam 7, the clamping part 6 is used to clamp and loosen the pile body 4, the beam 7 is connected with the pile frame 3, and the pile clamping mechanism can move up and down in the guide rail; The pile body coil 5 is fixed on the outside of the clamping part 6 as a whole, and is integrated with the pile body 4 through the pile clamping mec...

Embodiment 2

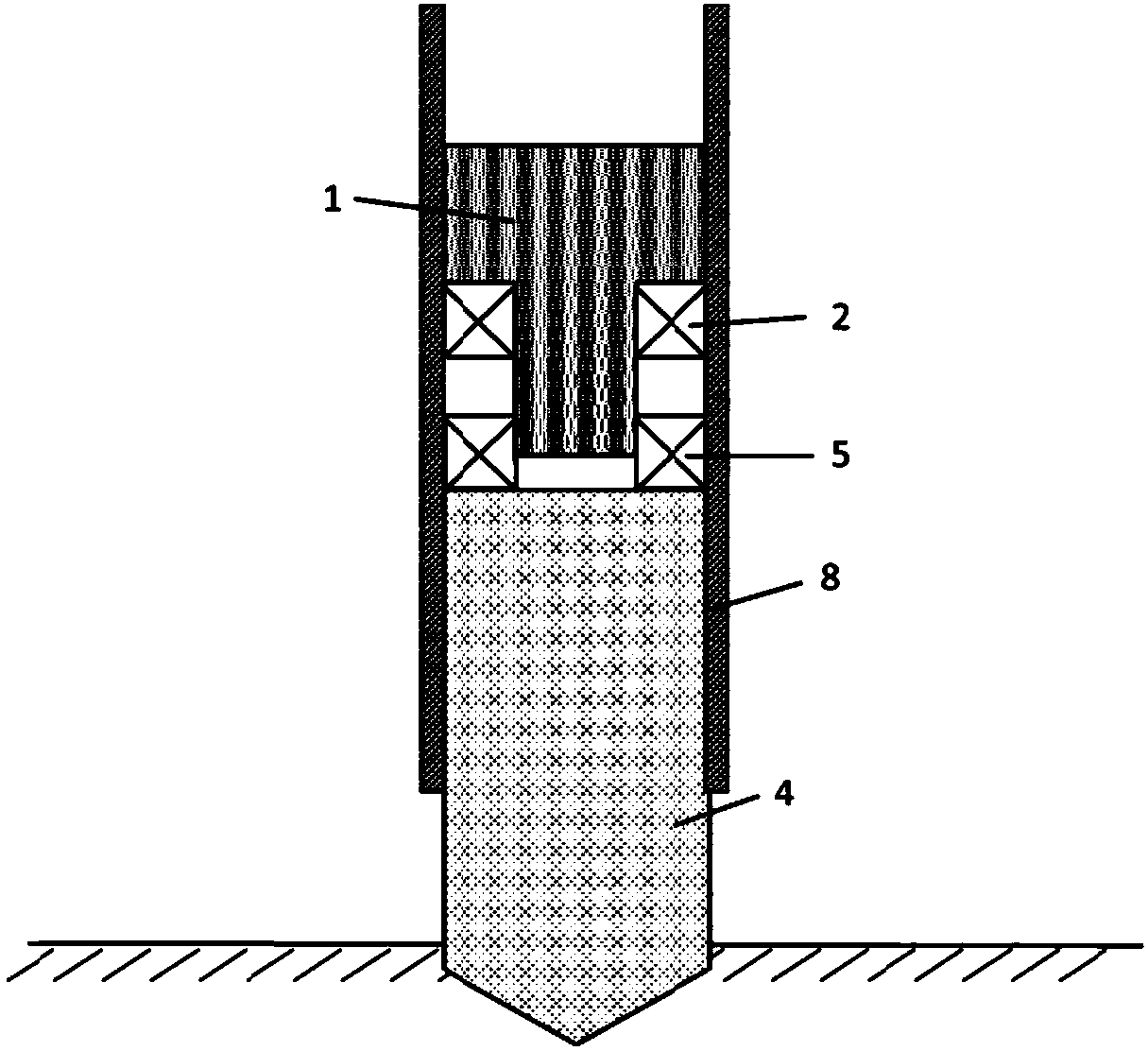

[0052] Such as figure 2 As shown, the overall structure of the piling device according to the embodiment of the present invention includes: a pile hammer 1 , a pile hammer coil 2 , a pile body 4 , a pile body coil 5 , and a guide sleeve 8 .

[0053] The pile hammer 1 is T-shaped and installed on the guide sleeve 8; the pile hammer coil 2 is fastened and connected to the lower part of the pile hammer 1 by bolts; the guide sleeve 8 is equipped with a guide rail structure, and a through hole is opened in the center, and the pile body 4 is located in the through hole, and the guide sleeve 8 can move up or down as a whole; the pile hammer 1 and the pile body 4 can move up and down in the guide sleeve 8; The pile head (that is, the pile cap) part; the pile body coil 5 and the pile hammer coil 2 are coaxially arranged, and the distance is relatively close to ensure that there is sufficient electromagnetic force between the two coils.

[0054] The piling method comprises the steps o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com