High-strength durable thin-walled cold-formed steel interior wall system

A cold-formed thin-walled steel and durable technology, which is applied to walls, building components, buildings, etc., can solve the problems of unguaranteed waterproof performance, high construction cost, complex structure, etc., and achieve good cost performance advantages, short construction period, and easy installation Quick and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

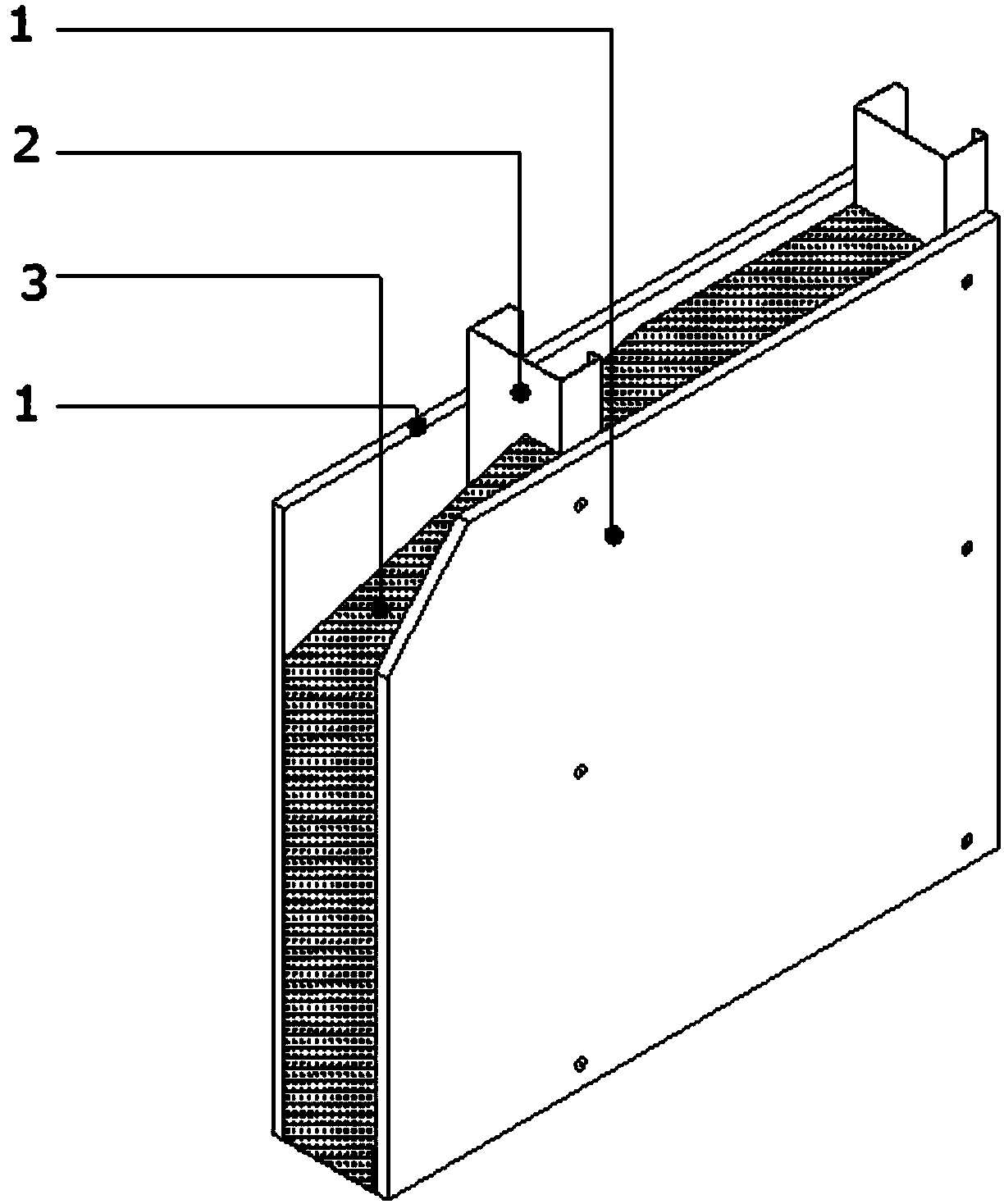

[0027] like figure 1 As shown, a high-strength and durable cold-formed thin-walled steel interior wall system includes glass magnesium board 1, cold-formed thin-walled steel column 2 and glass fiber cotton 3, glass magnesium board 1 is fixed on cold-formed thin-walled steel column 2 On both sides, glass fiber cotton 3 is filled in the wall.

[0028] The glass magnesium board 1 and the cold-formed thin-walled steel column 2 are connected by self-tapping screws.

[0029] The seams of the two layers of glass magnesium boards 1 are arranged in a staggered manner, and the seams are provided with airtight tapes.

[0030] In this embodiment, the thickness of the glass magnesium board 1 is 12mm, and the thickness of the glass fiber wool is 100mm.

[0031] The cold-formed thin-walled steel column 2 is U-shaped steel bent into an L shape.

[0032] The glass magnesium plate 1 is provided with a prefabricated hole, and the diameter of the prefabricated hole is 6mm.

[0033] Compared w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com