Electric power bin fireproof door for comprehensive pipe corridor

A technology for integrated pipe corridors and fire doors, which is applied to fire doors, cable installation in underground pipelines, and cable installation. It can solve problems such as personnel and equipment accidents, difficult cable laying, and threats to cable operation safety, and achieve convenient construction. , Reduce construction costs and operational safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

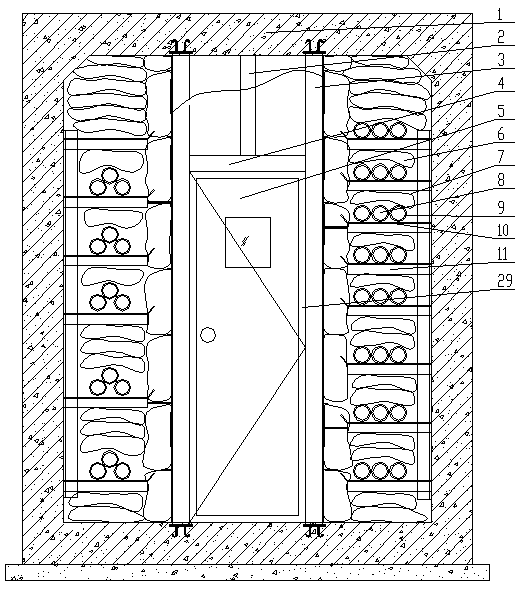

[0035] Embodiment 1. This embodiment provides a fire door for a power compartment of an integrated pipe gallery, which includes a tunnel body. A partition wall 11 is arranged on the inner side of the tunnel body 1 close to the inner side wall of the tunnel body 1, and a cable is arranged on the partition wall 11 A fireproof door is arranged between the partition walls 11;

[0036] The fire door includes a side door shaft 3 in contact with the partition wall 11. The upper and lower ends of the side door shaft 3 are connected to the tunnel body 1 by bolts, and a frame 29 is provided between the two side door shafts 3. A door body 5 is provided in the frame 29, a middle door shaft 2 is provided above the middle of the door body 5, a cross beam 4 is provided at the lower end of the middle door shaft 2, and the cross beam 4 is connected to the frame 29. The middle door shaft The upper end of 2 is connected with the tunnel body 1 by bolts. The frame is installed on the cross beams at ...

Embodiment 2

[0041] The second embodiment is different from the first embodiment:

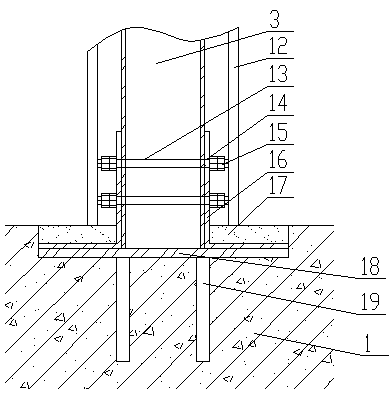

[0042] Where the side door shaft 3 and the tunnel body 1 are connected, a first mounting groove 17 is provided on the tunnel body 1, and a first connecting plate 18 is provided at the bottom of the first mounting groove 17, and the first connection A first embedded rod 19 is provided on the side of the plate 18 in contact with the tunnel body 1, the end of the side door shaft 3 is in contact with the first connecting plate 18, and the end of the side door shaft 3 is provided with a number of first bolts Perforation 13, a first fixed angle iron 16 is provided on both sides of the end of the side door shaft 3, and a second bolt perforation 14 is provided on the first fixed angle iron 16 corresponding to the first bolt perforation 13, and the first bolt perforation The first fixing bolt 15 is inserted into the 13 and the second bolt hole 14, and the other side of the first fixing angle iron 16 is in contact with ...

Embodiment 3

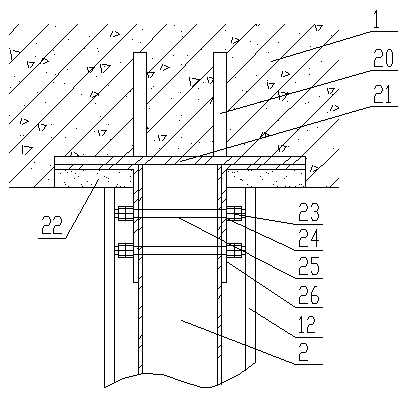

[0048] The third embodiment is different from the first embodiment:

[0049] A first refractory plate 27 is provided on both sides of the partition wall 11, and a through hole 28 is provided on the first refractory plate 27 corresponding to the cable 8. The first refractory board wraps both sides of the partition wall to prevent the refractory filler from falling off, and reflects the aesthetics, and the through holes are convenient for cables to pass through.

[0050] The side door shaft 3, the middle door shaft 2 and the cross beam 4 are provided with second refractory plates 12 on both sides. The second refractory plates wrap other areas except the door body excluding partition walls, and refractory fillers can also be placed inside them, Play the role of partition and support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com