Lateral type LED plant lighting panel light with light guide plate

A plant lighting and light guide plate technology, applied in lighting devices, fixed lighting devices, lighting device light guides, etc., can solve the problems of restricting the development of direct-type LED plant growth lamps, the high density of triangular array light sources, and the high density of light sources. The mixing effect is good, the light mixing effect is increased, and the light is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0027] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

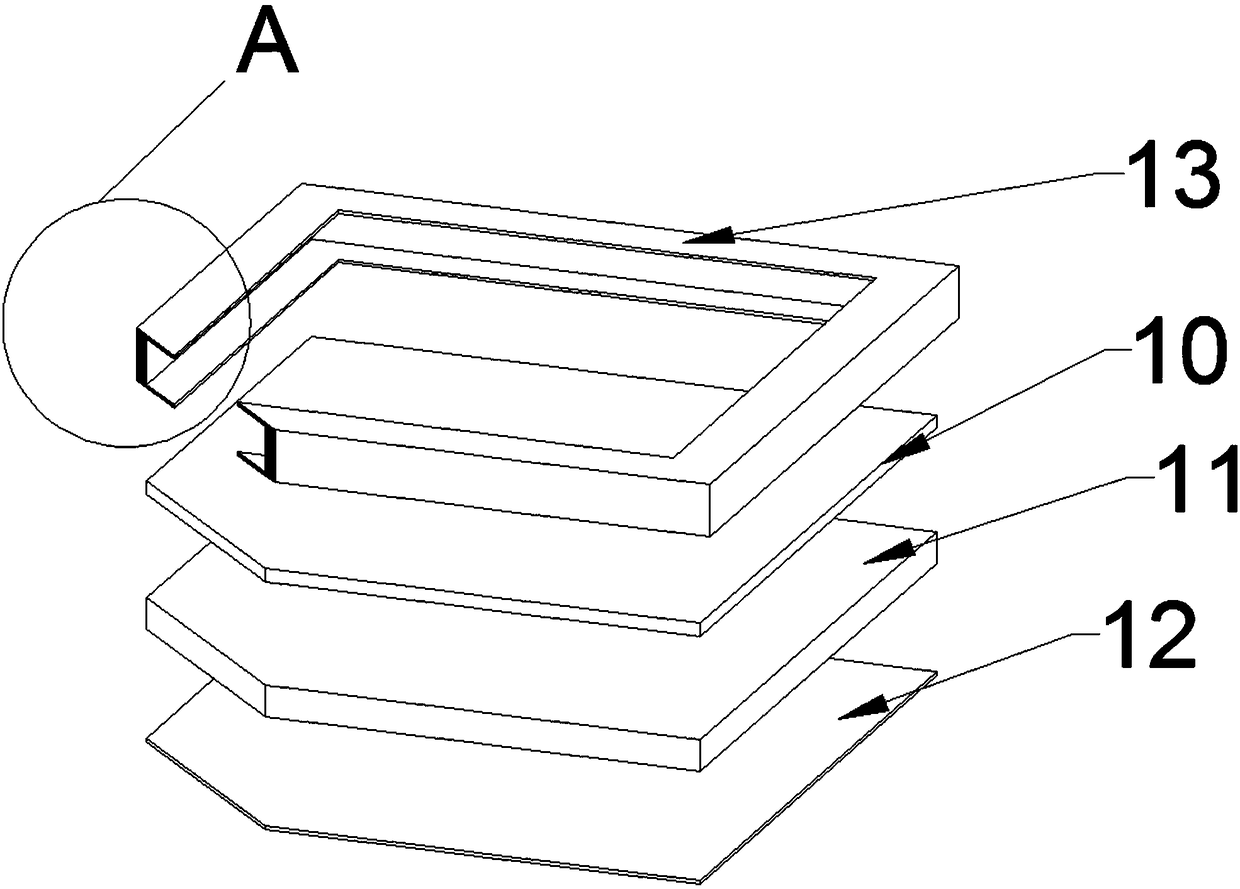

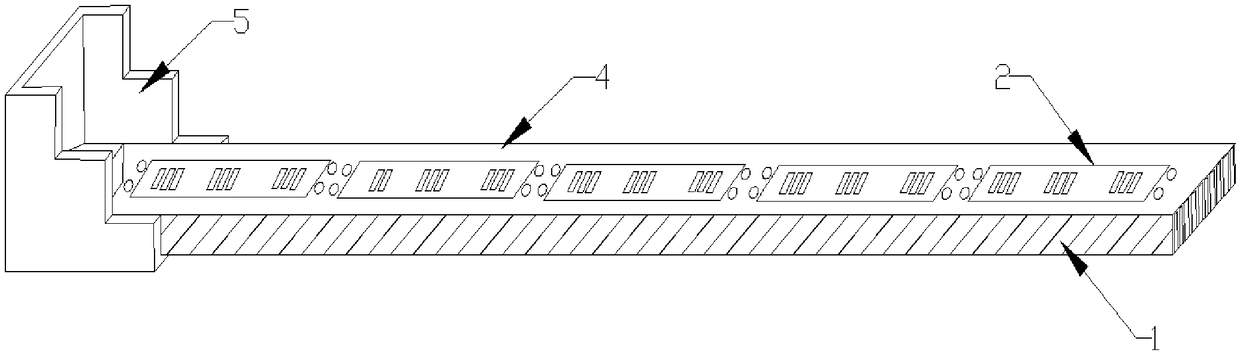

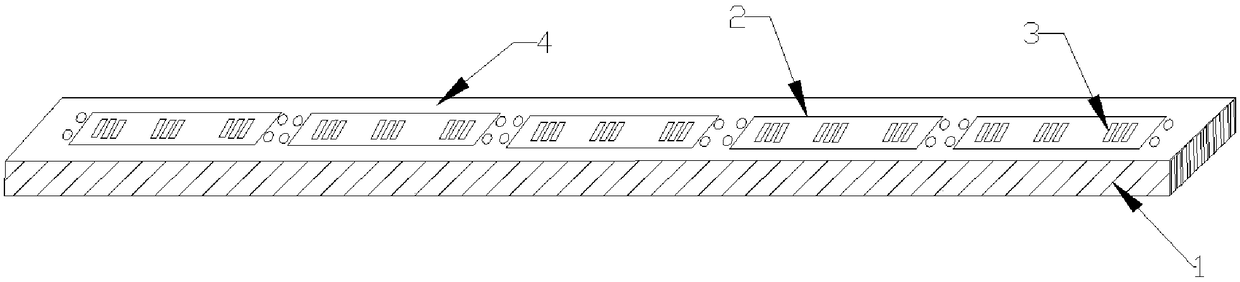

[0028] 1 is the heat dissipation aluminum plate, 2 is the LED unit, 3 is the LED light strip, 4 is the insulating reflective layer, 5 is the corner connecting block, 6 is the filling block, 7 is the connecting plate, 8 is the first plate, 9 is the second plate, 10 is a light emitting panel, 11 is a light guide plate, 12 is a reflector, 13 is a casing, 14 is a side plate, 15 is a bottom plate, 16 is an LED light source plate, and 17 is a light mixing element.

[0029] For the convenience of description, the directions mentioned below are explained as follows: the up and down directions mentioned below are related to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com