Chuck device and semiconductor processing equipment

A chuck and base technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as metal particle pollution, product quality impact, etc., to reduce metal pollution, improve temperature field and electric field uniformity, Improving the effect of uneven temperature distribution and steep electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order for those skilled in the art to better understand the technical solution of the present invention, the chuck device and the semiconductor processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

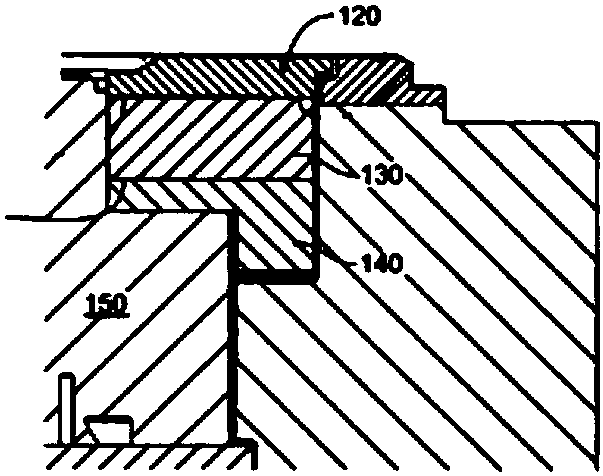

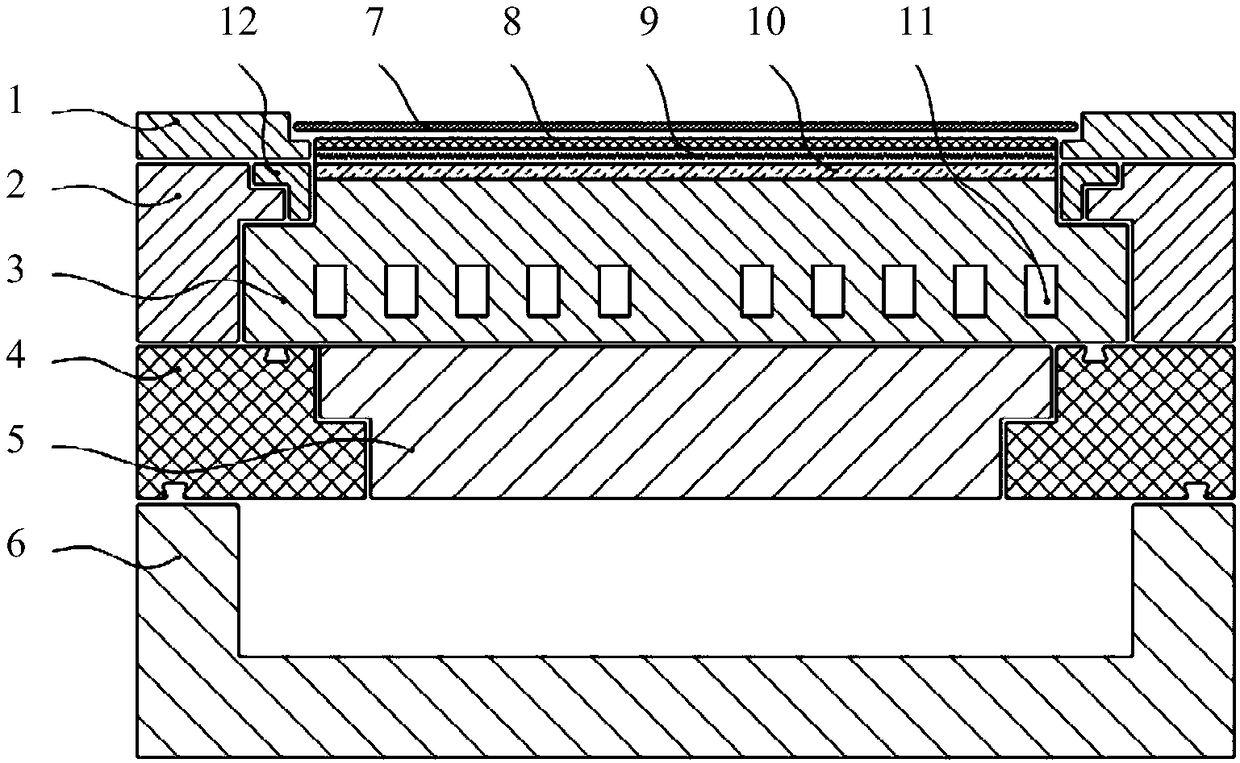

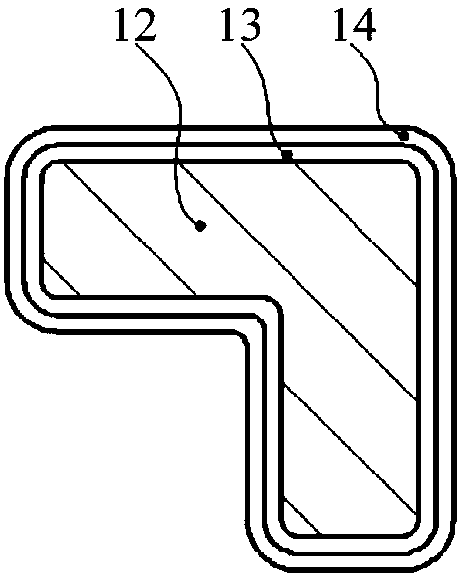

[0030] figure 2 It is a sectional view of the chuck device provided by the embodiment of the present invention. image 3 for figure 2 Cross-sectional view of a medium-heat edge ring. Please also refer to figure 2 and image 3 , The chuck device provided in this embodiment includes a base 3 , a base ring 2 , a focus ring 1 , an insulating ring 4 , an interface plate 5 , and a fixing member 6 . Wherein, an insulating layer 8, a heating layer 9 and a heat insulating layer 10 are sequentially arranged on the base 3 from top to bottom, wherein a DC electrode layer (not shown) is arranged in the insulating layer 8 to generate The electrostatic attraction fixes the chip 7 on the upper surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap