Waterborne lubricating oil containing lithium silicate and preparation method thereof

A technology of lubricating oil and lithium silicate, applied in the field of lubricating oil, can solve the problems of adverse effects on operators and the environment, poor water solubility of lubricating oil, inconvenient cleaning, etc., and achieve the effect of protecting health, simple components and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

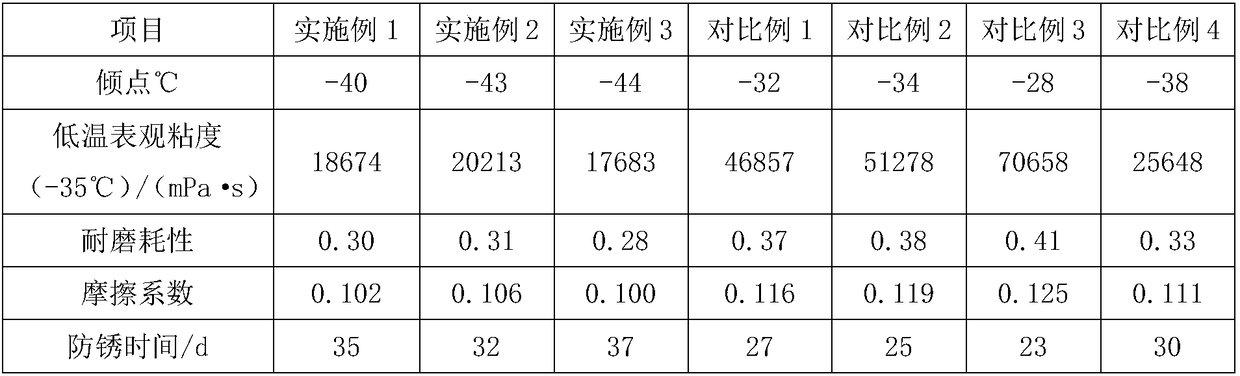

Examples

Embodiment 1

[0024] An aqueous lubricating oil containing lithium silicate, said aqueous lubricating oil comprising the following raw materials in parts by weight: 48 parts of water-soluble base oil, 11 parts of lithium silicate, 10 parts of allantoin, 8 parts of potassium sodium tartrate, 6 parts of γ-polyglutamic acid and 4 parts of honey.

[0025] A method for preparing an aqueous lubricating oil containing lithium silicate, the steps are: A. Mix lithium silicate and allantoin, add 2 times the weight of the mixture of water, and place the mixture at 112°C and stir for 3 hours to obtain a mixed liquid one ; B. Add potassium sodium tartrate, γ-polyglutamic acid and honey to 2 times the weight of each raw material to prepare a solution of potassium sodium tartrate, γ-polyglutamic acid and honey; C. Combine water-soluble base oil with The mixed solution obtained in step A was stirred and reacted at 60°C for 20 minutes to obtain mixed solution two; D. Potassium sodium tartrate and γ-polyglutami...

Embodiment 2

[0027] An aqueous lubricating oil containing lithium silicate, which comprises the following raw materials in parts by weight: 87 parts of water-soluble base oil, 17 parts of lithium silicate, 16 parts of allantoin, 16 parts of potassium sodium tartrate, 15 parts of γ-polyglutamic acid and 8 parts of honey.

[0028] A method for preparing an aqueous lubricating oil containing lithium silicate, the steps are: A. Mixing lithium silicate and allantoin, adding 6 times the weight of the mixture of water, and stirring at 125°C for 5 hours to obtain a mixed solution one B. Add potassium sodium tartrate, γ-polyglutamic acid and honey to 3 times the weight of each raw material to prepare a solution of potassium sodium tartrate, γ-polyglutamic acid and honey; C. Combine water-soluble base oil with The mixture obtained in step A was placed at 80°C and stirred for 35 minutes to obtain mixture two; D. Potassium sodium tartrate and γ-polyglutamic acid were placed at 70°C and stirred and reacte...

Embodiment 3

[0030] An aqueous lubricating oil containing lithium silicate, which comprises the following raw materials in parts by weight: 74 parts of water-soluble base oil, 13 parts of lithium silicate, 14 parts of allantoin, 12 parts of potassium sodium tartrate, 10 parts of γ-polyglutamic acid and 6 parts of honey.

[0031] A method for preparing water-based lubricating oil containing lithium silicate, the steps are:

[0032] A. Mix lithium silicate and allantoin, add 4 times the weight of water to the mixture, and place the mixture at 118°C and stir for 4 hours to obtain mixed solution 1.

[0033] B. Add potassium sodium tartrate, γ-polyglutamic acid and honey to 2.3 times the weight of each raw material to prepare a solution of potassium sodium tartrate, γ-polyglutamic acid and honey.

[0034] C. Place the water-soluble base oil and the mixed liquid obtained in step A at 70° C. and stir for 25 minutes to obtain mixed liquid two.

[0035] D. Put potassium sodium tartrate and γ-polyglutamic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com