Environment-friendly continuous production integrated device and process for degreasing cotton

A production process and integrated device technology, applied in the field of absorbent cotton green continuous production integrated device, can solve the problems of serious pollution, high production cost, low utilization rate of production enterprises, etc., achieve high process efficiency, reduce manufacturing cost, and be conducive to environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

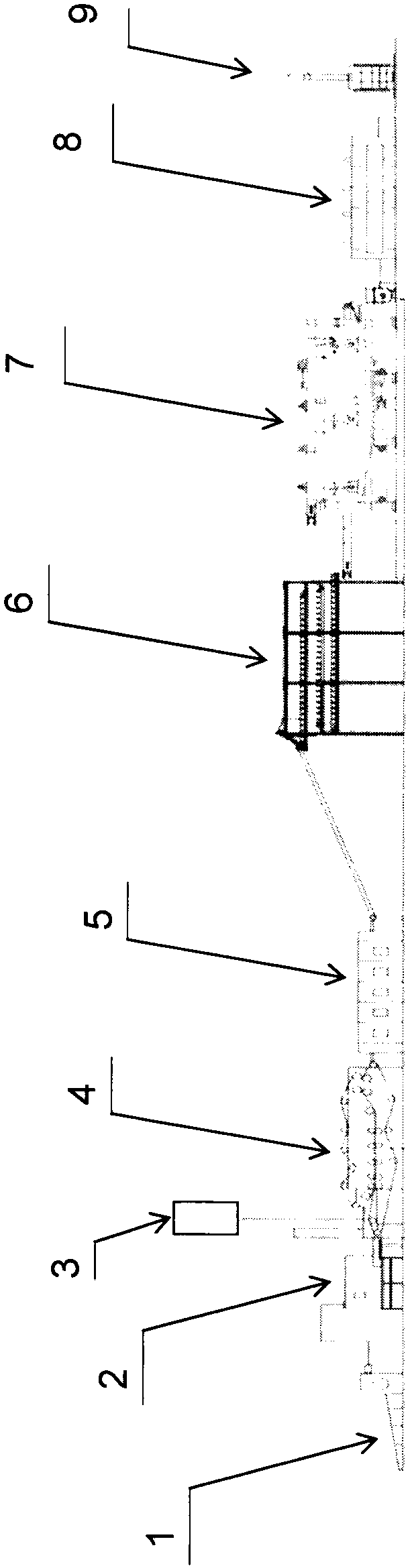

[0030] A green continuous production integrated device for absorbent cotton, including cotton bale opening machine 1, quilt finishing machine 2, hydroxyl radical active oxygen pharmaceutical machine 3, high-efficiency impregnation machine 4, catalytic degreasing and decolorizing reactor 5, continuous degreasing and decolorizing reactor 6, Belt washing machine 7, drying equipment 8, packing equipment 9; Wherein, described cotton bale opener 1 comprises the cotton bale opener entrance of receiving cotton bales, unpacking equipment and cotton bale opener entrance; Described cotton bale opener entrance receives Cotton bales are bundled, and the cotton bale is opened by the cotton bale opening device, the outlet of the cotton bale unpacking machine is connected to the import of the quilt finishing machine, and the outlet of the quilt finishing machine 2 is connected to the cotton inlet of the high-efficiency dipping machine 4, At the same time, the drug outlet of the hydroxyl radica...

Embodiment 2

[0033] A green continuous production integrated device for absorbent cotton, comprising a cotton bale opener 1 (that is, a cotton opener), a quilt finishing machine 2, a hydroxyl radical active oxygen pharmaceutical machine 3, a high-efficiency dipping machine 4, a catalytic degreasing and decolorizing reactor 5, Continuous degreasing and decolorizing reactor 6, belt washing machine 7, drying equipment 8, packing equipment 9; Wherein, described cotton bale opener 1 comprises the cotton bale opener entrance, unpacking equipment and cotton bale opener entrance that receive cotton bales; The entrance of the cotton bale opening machine described above receives bundled cotton bales, and the cotton bale unpacking device is opened by the cotton bale opening machine. The cotton inlet of the dipping machine 4, and the drug outlet of the hydroxyl radical active oxygen pharmaceutical machine 3 are connected to the drug inlet of the high-efficiency dipping machine through a pipeline. The h...

Embodiment 3

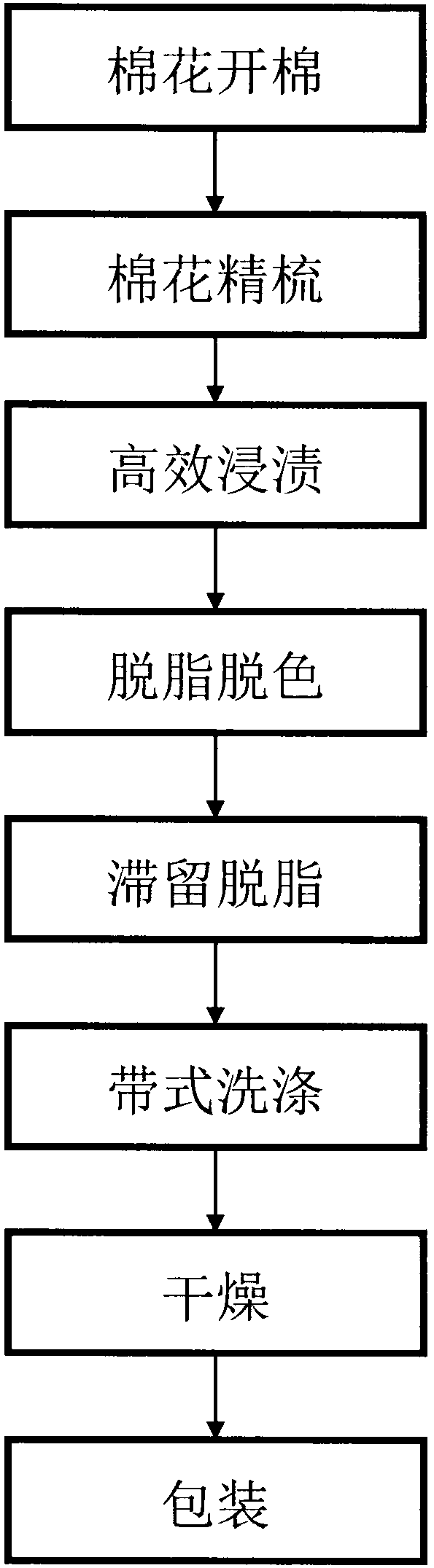

[0036] A green continuous production process for absorbent cotton, comprising the steps of:

[0037] The raw cotton is opened in the cotton bale opener 1; the material after opening is transported to the quilt finishing machine 2 to be sorted into a quilt shape, and the quilt-like material after sorting is transported to the high-efficiency dipping machine 4, where the high-efficiency dipping machine Inside, mix and impregnate with the medicament prepared by the hydroxyl radical active oxygen pharmaceutical machine 4; the impregnated material enters the catalytic degreasing and decolorizing reactor 5 for catalytic degreasing and decolorizing reaction, and the reacted material is further transported to the continuous degreasing and decolorizing reactor 6 for further Degreasing and decolorizing treatment, the processed material enters the belt washing machine 7 for washing treatment, the washed material is dried, and the dried material is packed in the packing device 8 to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com