A kind of fabric concrete composite block and preparation method

A technology of concrete and fabric, applied in the direction of building structure, building, building components, etc., can solve the problems of hollow plastering on the surface, easy cracking of the wall, low block strength, etc., to reduce interference, improve frost resistance and performance Thermal insulation performance, effect of reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

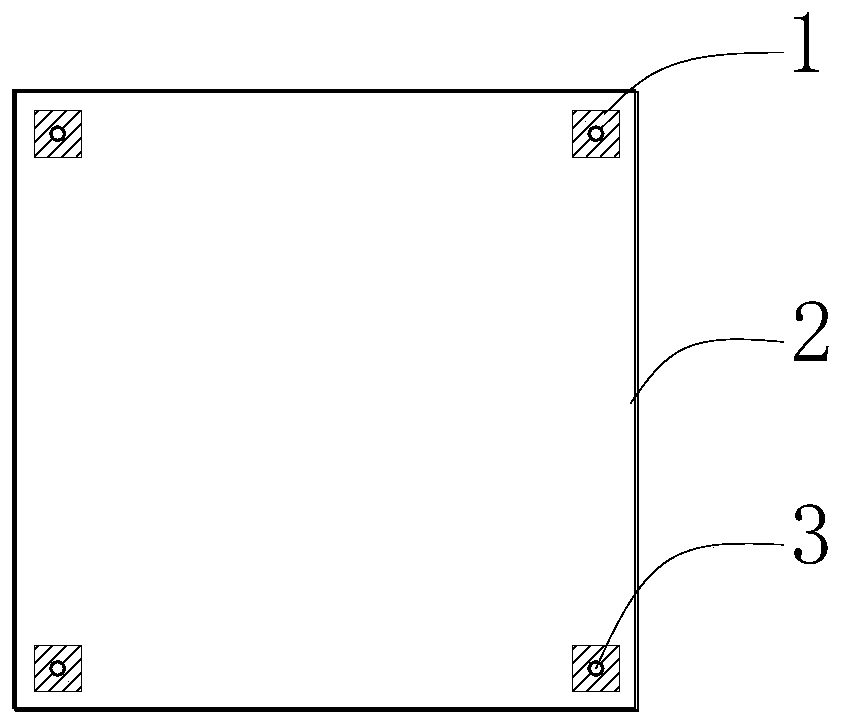

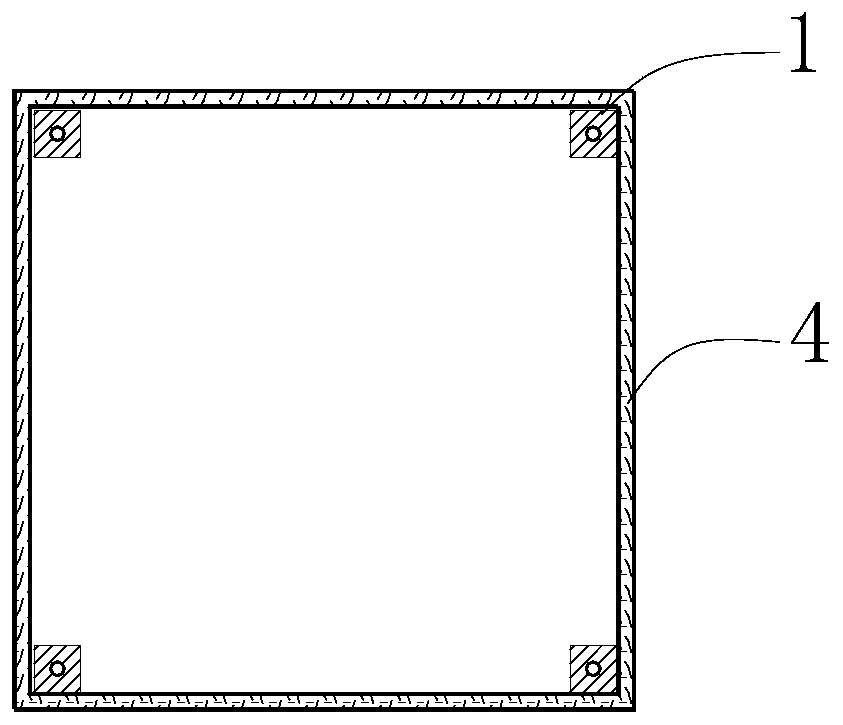

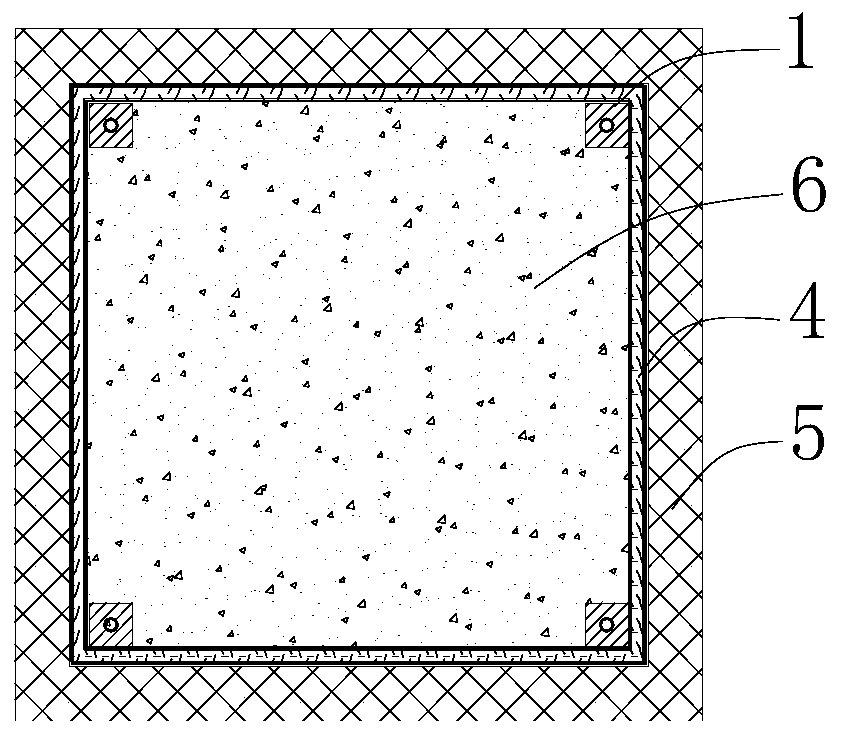

[0031] A kind of fabric concrete composite block of the present invention, as Figure 4 As shown, it includes four columns 1 arranged to form the corners of a rectangular tube, a fabric tube 4 that is wound and fixed on the column 1 to form a rectangular cylindrical structure, and a filler 6 filled inside the fabric shell 1; the horizontal column 1 The cross-section is rectangular, and the relative positions of the four columns 1 are fixed to form a lattice-type core cage. The lattice-type core cage is integrated with the fabric after it is wound, and defines the filling space of the filler. Wherein, the fabric cylinder 4 is formed by winding canvas, organic fibers or inorganic fibers. Column 1 adopts wooden, bamboo or organic material. The two ends of the four columns 1 are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com