Projectile internal charging structure for preventing flame-over ignition of fuse in explosive-proof state

A fire isolation and fuze technology, which is applied to ammunition, cartridge ammunition, offensive equipment, etc., to solve hidden safety hazards and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

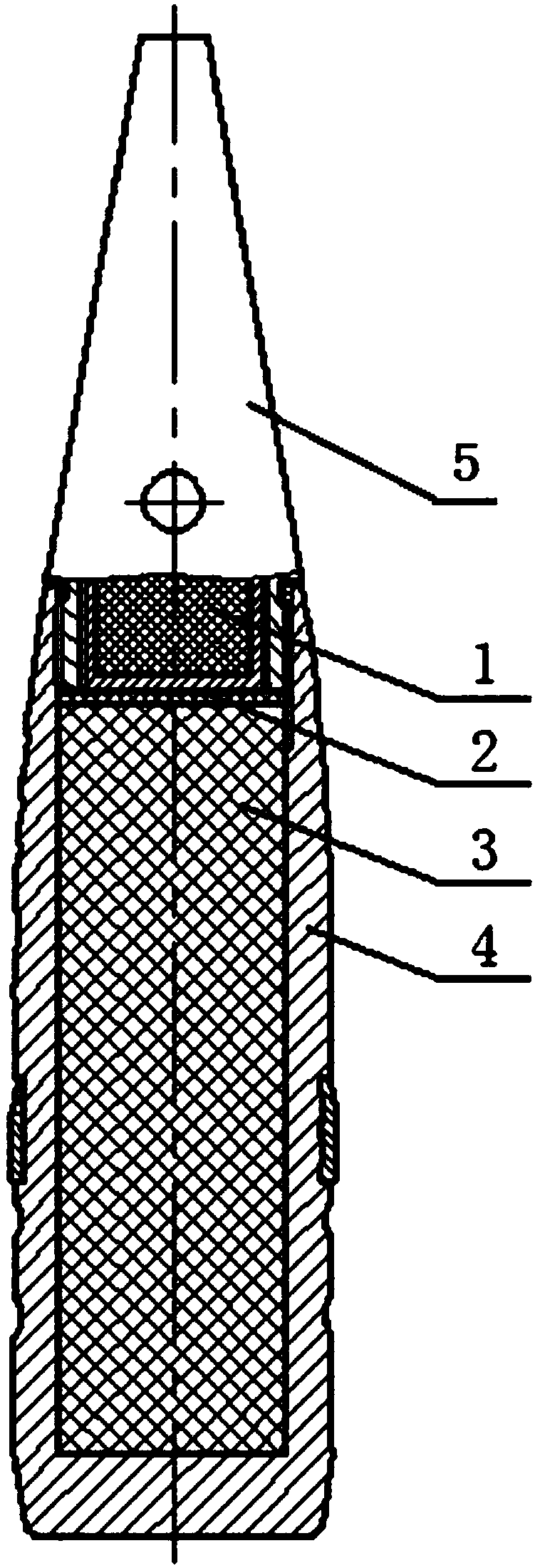

Embodiment 1

[0019] combine figure 1 , The fire-insulating member 2 of the present invention can be heat-insulating paint or heat-insulating glue (such as GD-433 flame-retardant single-component room temperature vulcanized silicone rubber), and can also be fire-insulating and heat-insulating gaskets such as aluminum foil or tin foil. The heat insulation paint or heat insulation glue or aluminum foil or tin foil and other fire and heat insulation gaskets are directly assembled between the top of the explosive charge 3 and the fuze detonator tube 1 . In addition, the heat-insulating paint or glue and heat-insulating gaskets such as aluminum foil or tin foil should ensure good compatibility with the grain.

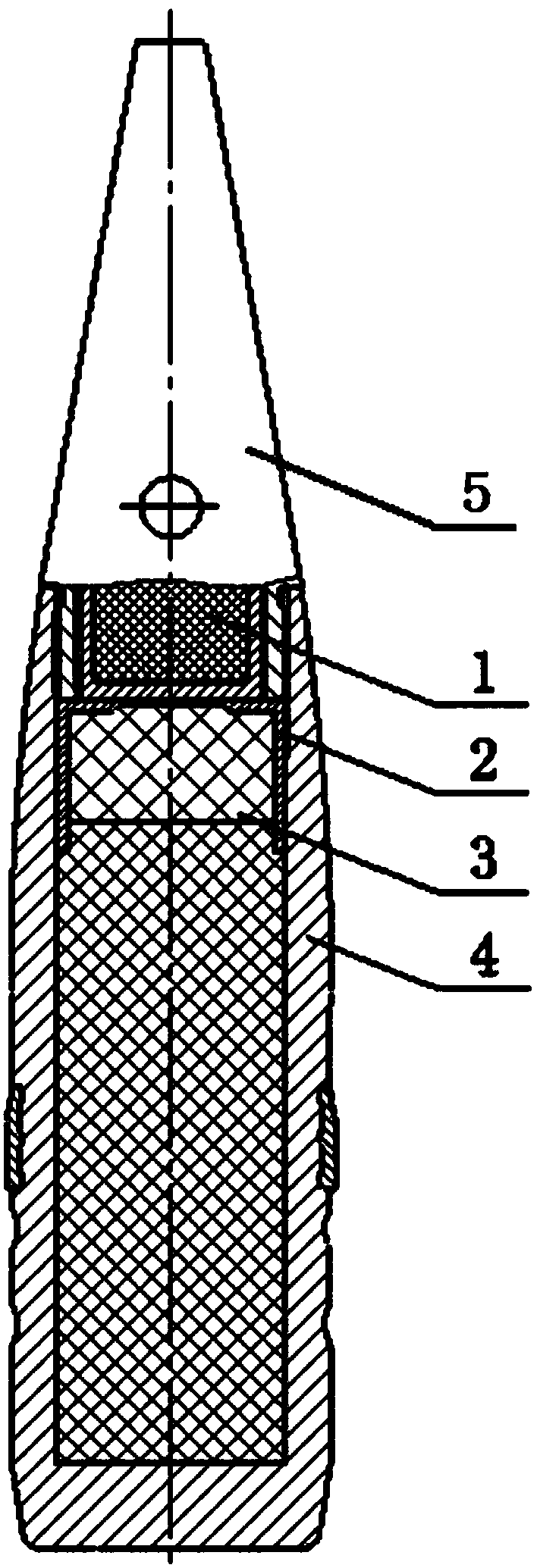

Embodiment 2

[0021] combine figure 2 , The fire barrier 2 of the present invention is a reinforced cap, and its structural principle is the same as that of the detonator reinforced cap. The reinforcing cap is directly assembled on the top of the propellant charge 3 . The shape of the reinforcing cap changes accordingly according to the shape of the fuze booster tube 1, so as to ensure that its inner surface is in direct contact with the propellant charge 3, and its outer surface is in close contact with the outer contour of the fuze booster tube. The thickness of the middle part of the top layer of the reinforcing cap is thinner than that of the two sides of the top layer. This structure can not only isolate the high-temperature and high-pressure gas leaking through the potential fire transmission path to achieve the purpose of fire isolation, but also does not affect the detonation output of the detonator tube. Completely detonate the projectile or the warhead, and the material of the r...

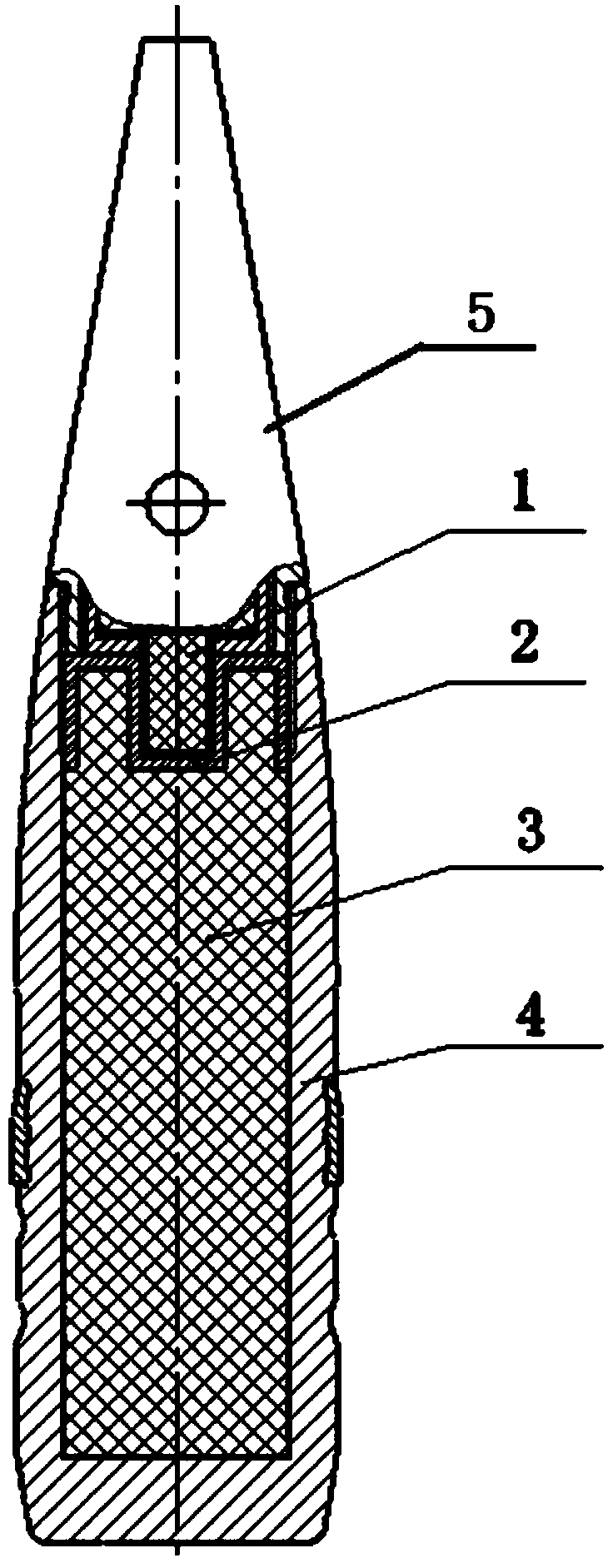

Embodiment 3

[0023] combine image 3 , the middle part of the fire-proof element 2 is a concave structure, so as to ensure that the inner surface of the fire-proof element is in contact with the main charge of the ammunition, and the outer surface is in close contact with the protruding booster tube of the flameproof fuze.

[0024] The present invention prevents the detonator from accidentally igniting, exploding, and leaking high-temperature and high-pressure gas to accidentally ignite the projectile or the internal fire explosive charge of the warhead. The working process of the charging structure is as follows:

[0025] During service processing and firing in the bore and within the safe distance of the muzzle, if the sensitive explosive element in the flameproof fuze accidentally ignites, since the fuse is not released at this time and is in an explosion-proof state, the high-temperature and high-pressure gas produced by the explosive element will It will not detonate the guide and det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com