A Finite Element Optimization Method for Protecting the Width of Coal Pillars in Floor Roadway

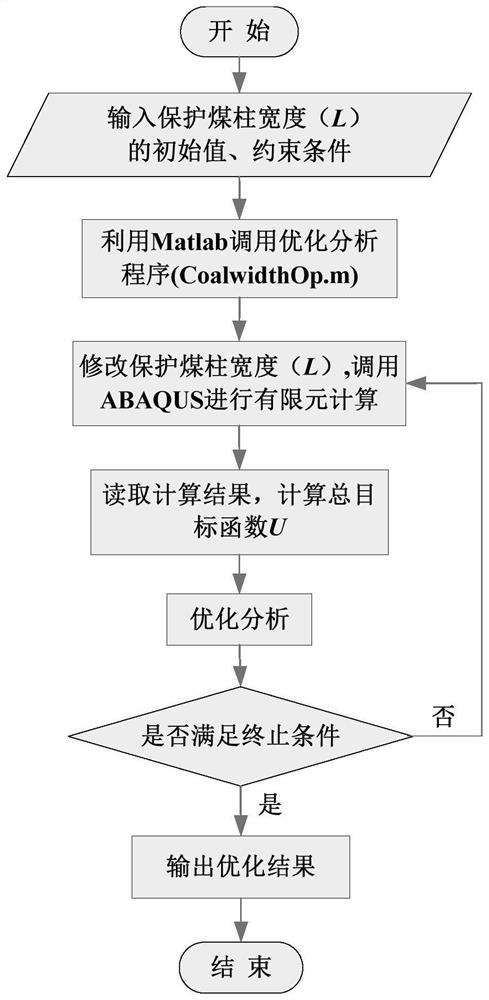

A technology for protecting coal pillars and optimizing methods, applied in the field of floor roadway protection of coal pillar width and finite element optimization, can solve the problems of reduced analysis efficiency, easy to ignore optimal solutions, impossible to establish all solutions, etc., to improve analysis efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] The floor strata of the 42010 working face of a coal mine project are dominated by siltstone, and the floor roadway is located 26m below the coal seam, with a buried depth of 610m. The roadway adopts a straight wall semi-circular arch section with a clear width of 5000mm and a clear height of 6800mm. The roadway is supported by anchor spraying and the concrete thickness is 200mm. In the roadway excavation, the anchor cable support parameters are φ22mm×7500mm, and the row spacing is 1200mm×1200mm. The bottom plate adopts φ22mm×8300mm high-strength steel strand anchor cables, and the row spacing is 1300mm×1300mm.

[0053] Columnar distribution of rock formations such as Figure 4 As shown, the support section is as Figure 5 shown.

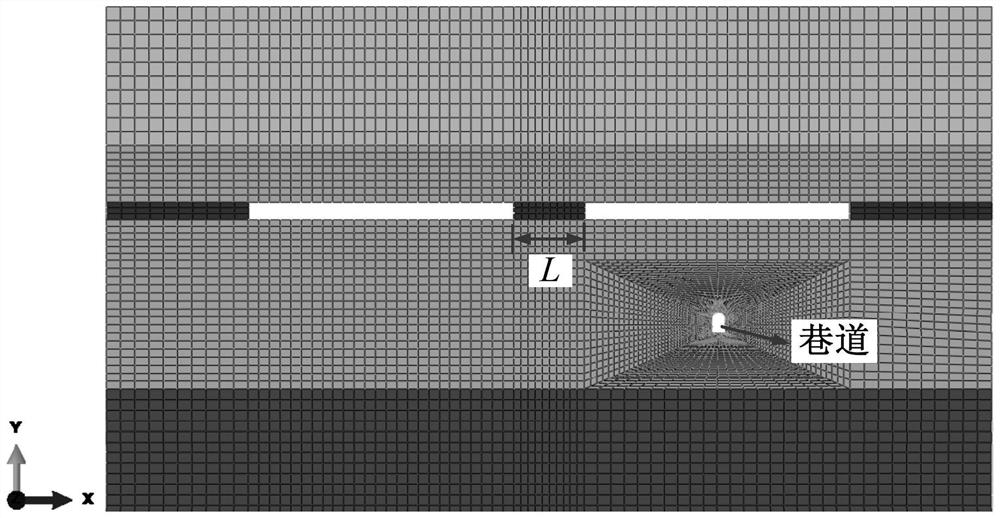

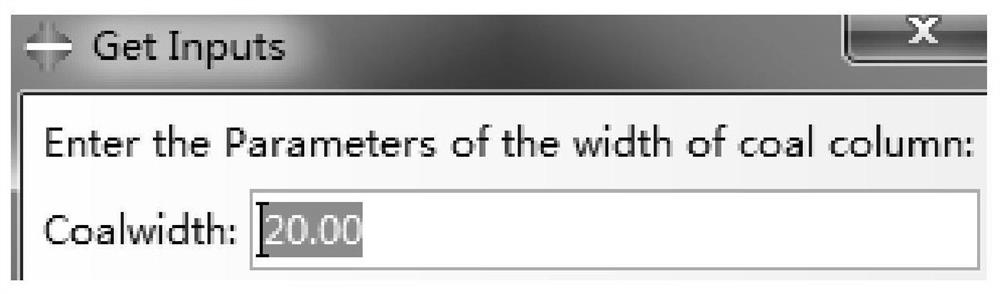

[0054] Using the standard design language Python of the large-scale finite element software ABAQUS to compile a parametric variable model capable of simulating different reserved coal pillar widths, such as figure 1 As shown, in order to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com