Cargo location optimization method of automatic three-dimensional warehouse of pharmaceutical enterprise and system thereof

A three-dimensional warehouse and optimization method technology, applied in the field of logistics and warehousing, can solve problems such as only considering the turnover rate of goods and shelf stability, unsatisfactory optimization results, and inability to describe practical problems well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

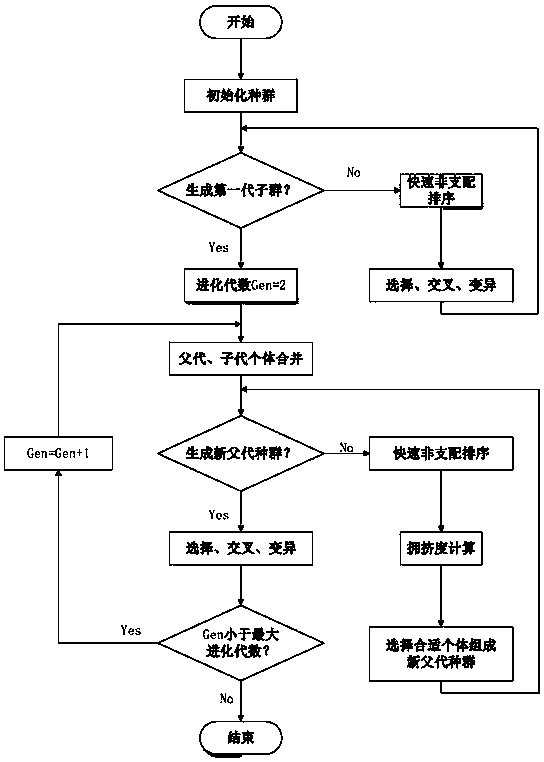

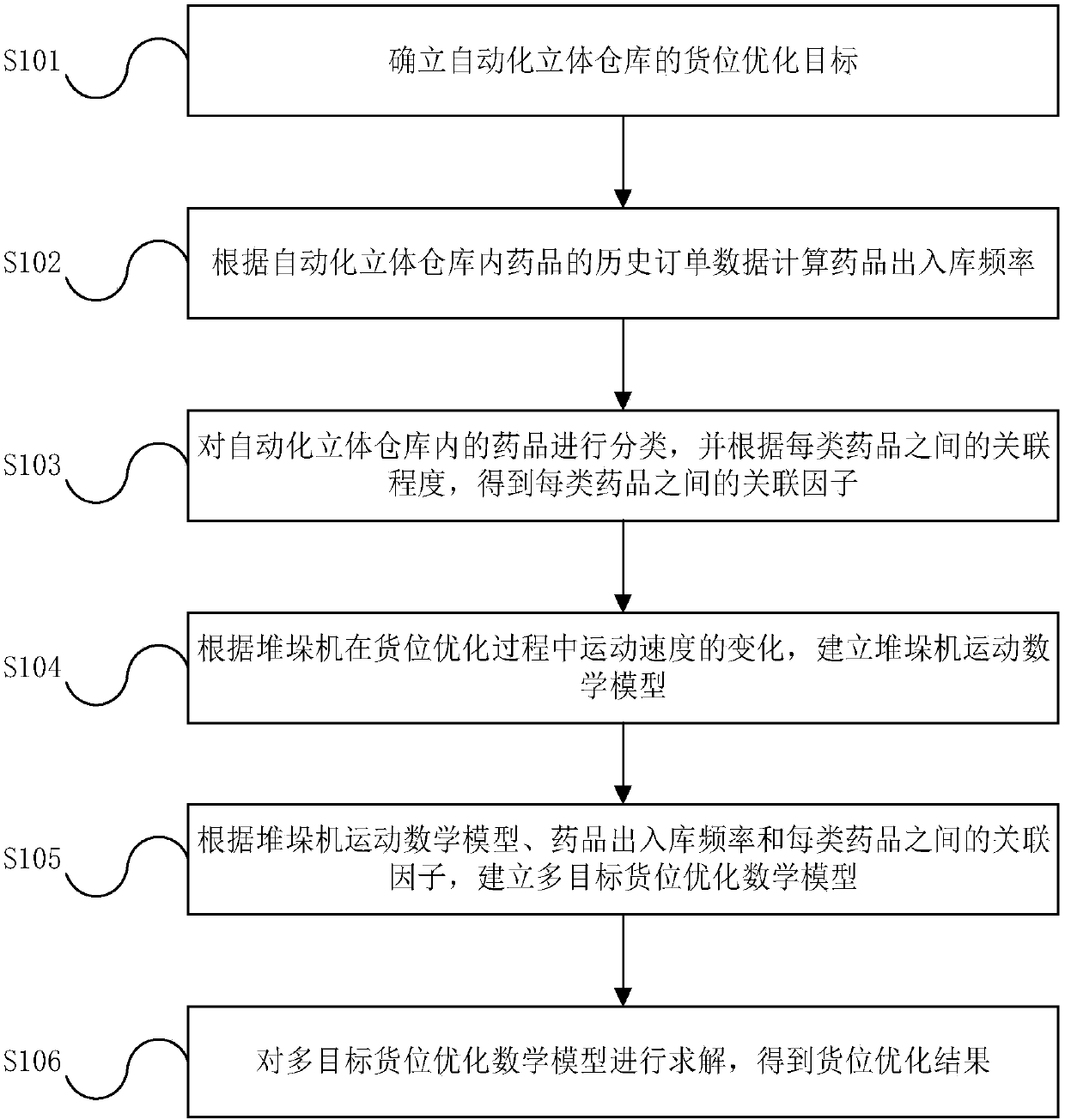

[0067] refer to figure 1 According to the first embodiment of the present invention, the cargo location optimization method of the automated three-dimensional warehouse of a pharmaceutical enterprise includes:

[0068] Step S101, establishing the cargo location optimization goal of the automated three-dimensional warehouse;

[0069] Step S102, calculating the frequency of medicines entering and leaving the warehouse according to the historical order data of medicines in the automated three-dimensional warehouse;

[0070] Step S103, classify the drugs in the automated three-dimensional warehouse, and obtain the correlation factor between each type of drugs according to the degree of correlation between each type of drugs;

[0071] Step S104, according to the change of the movement speed of the stacker during the cargo location optimization process, a mathematical model of the movement of the stacker is established;

[0072] Step S105, according to the mathematical model of th...

Embodiment 2

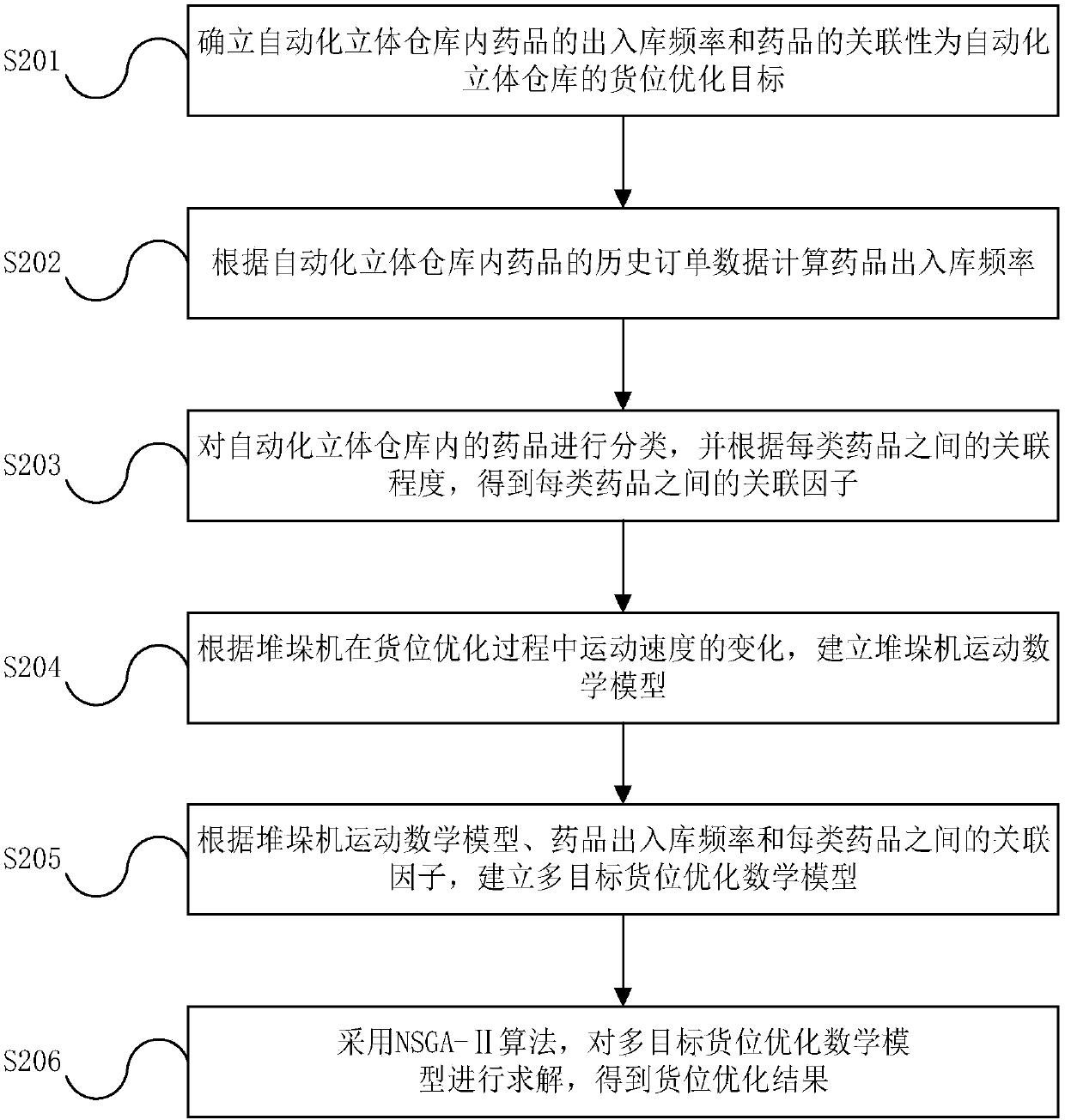

[0081] refer to figure 2 , the cargo location optimization method of the automated three-dimensional warehouse of a pharmaceutical enterprise provided by Embodiment 2 of the present invention includes:

[0082] Step S201, establishing the relationship between the frequency of medicines entering and leaving the warehouse in the automated warehouse and the correlation between medicines as the cargo location optimization goal of the automated warehouse.

[0083] Step S202, calculating the frequency of medicines entering and leaving the warehouse according to the historical order data of medicines in the automated three-dimensional warehouse.

[0084] Specifically, within a production cycle, the frequency of entry and exit of the jth drug in category i is:

[0085]

[0086] Among them, p ij is the frequency of entry and exit of the jth drug in the i category, M ij is the total number of stock-in and out of the j-th drug of category i in the corresponding production cycle, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com