Hydrogenation-reactor inner-guide technology and design method and application thereof

A hydrogenation reactor and reactor technology, applied in chemical instruments and methods, petroleum industry, chemical/physical/physicochemical processes, etc., can solve the problems of large temperature difference between the upper and lower reactors, too thick air cushion, etc., and achieve medium flow Longer, less fatigue, less effect on the probability of contact with light component outlets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

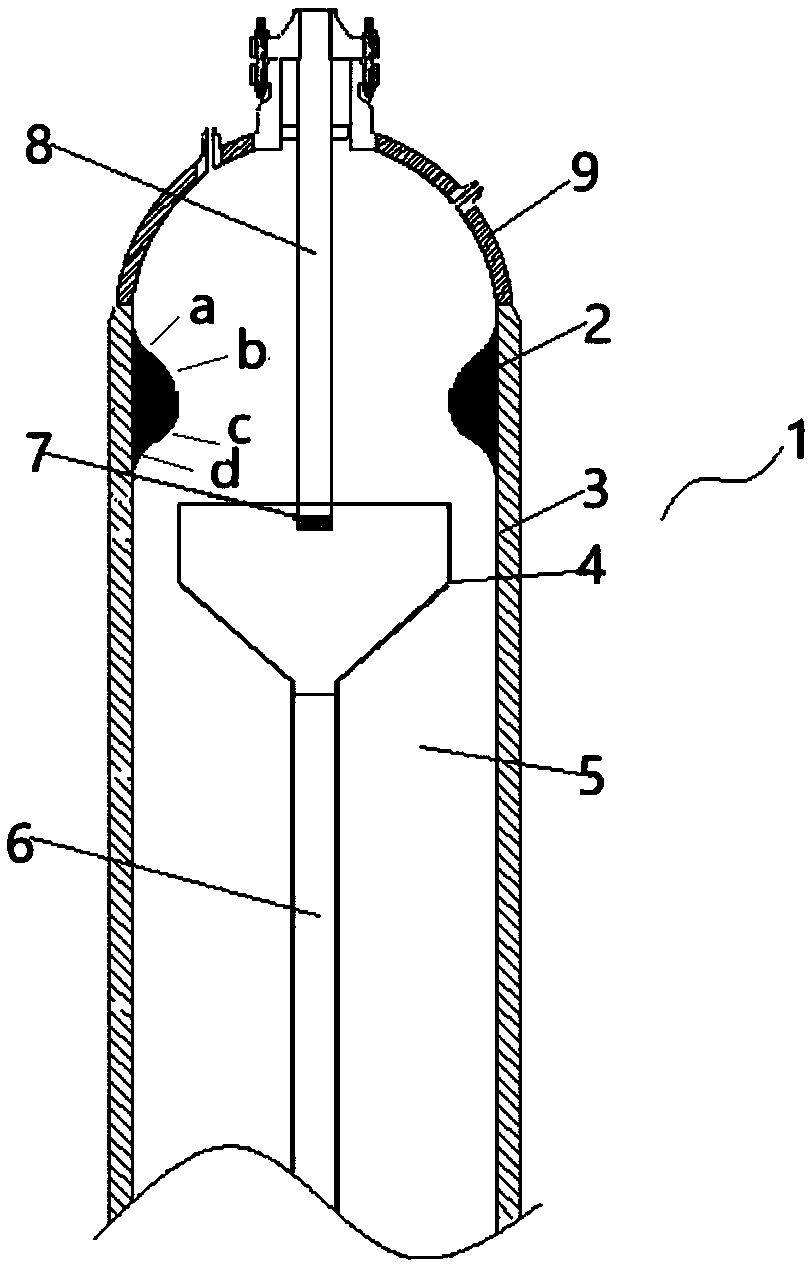

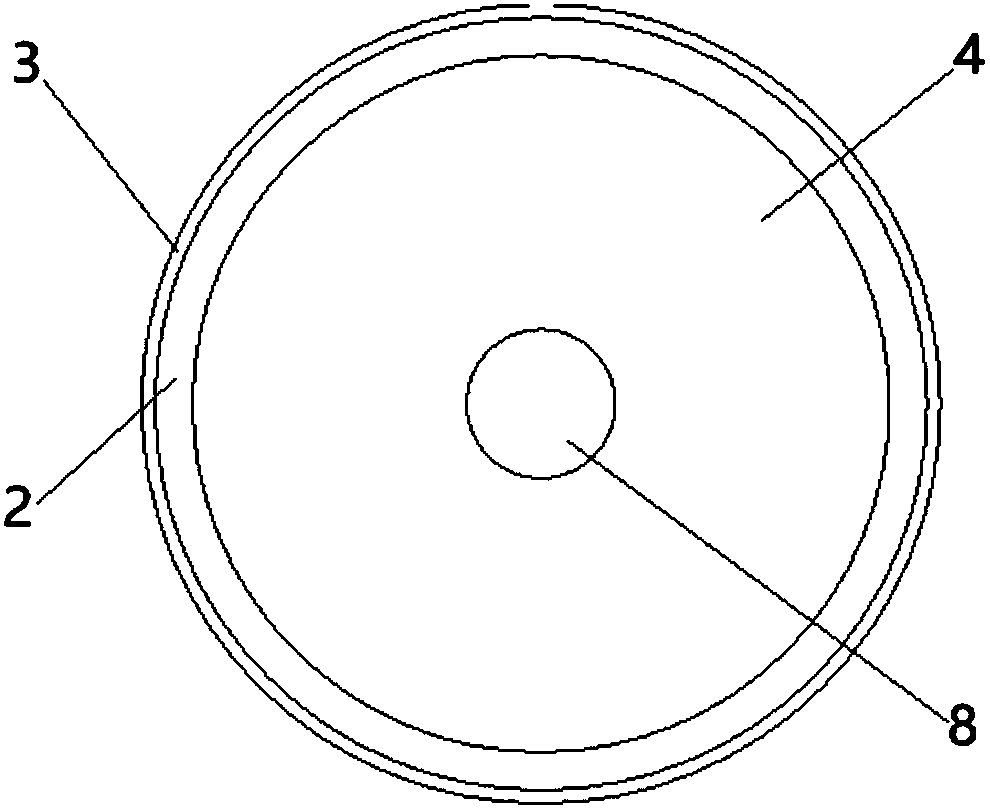

[0028] Such as figure 1 As shown, a kind of internal diversion hydrogenation reactor adopted in the process of this embodiment includes a reactor cylinder 1, and the reactor cylinder 1 includes a reactor head 9, a reactor body 3, and a reactor body 3 A round guide ring 2 is installed on the upper part of the inner wall, and a reactor discharge pipe 8, a guide tube distributor 4, a guide tube 6, and a guide tube distributor 4 are installed in the center of the reactor cylinder 1 from top to bottom. It is funnel-shaped, the upper surface is flush with or slightly lower than the bottom end of the guide ring 2, the top of the reactor discharge pipe 8 passes through the top outlet of the reactor cylinder 1, and the bottom end is located below the guide ring 2 and inserted into the guide ring 2. The tube distributor 4 has a length of 10 mm, and the top end of the draft tube 6 is connected to the bottom end of the draft tube distributor 4 . The guide ring 2 is an annular structure w...

Embodiment 2

[0031] This embodiment is a slurry bed hydrogenation reactor used in the residual oil slurry bed hydrogenation process. The overall structure is similar to that of Example 1. The inner diameter of the reactor cylinder 1 is 800mm, and the inner diameter of the upper opening end of the draft tube distributor 4 is The vertical height of the diversion ring 2 is 15mm, and the maximum width of the horizontal protrusion is 150mm. The heavy component flows upward from the bottom of the reactor cylinder 1, and enters the diversion tube distributor after being diverted by the diversion ring 2 In 4, under the action of gravity, the light and heavy components of the reactants enter the diversion tube distributor 4 and flow in layers in the horizontal direction, and the heavy components are farthest from the outlet pipe 8 of the reactor, which reduces the contact with the light component outlet. The probability is low, and it is not easy to form coke at the light component outlet. The light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com