Tool for cutting off packaged flat steel and manufacturing method

A technology for cutting packaging and manufacturing methods, which is applied in the direction of shearing devices, manufacturing tools, metal processing equipment, etc., can solve the problems of finger injury, time-consuming and laborious, small gap between packaging flat steel and section steel, etc., and achieves simple and convenient use of tools and improved The effect of work efficiency and simple tool structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

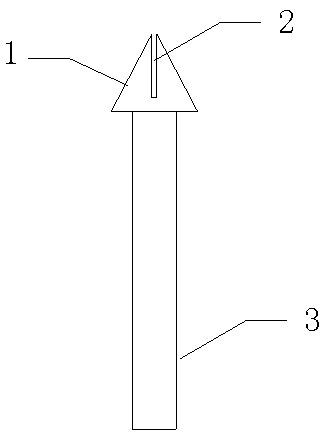

[0032] The tool for cutting packaging flat steel of the present invention includes a cutting head and a handle.

[0033] see now figure 1 , figure 1 It is a structural schematic diagram of a tool for cutting packaging flat steel according to an embodiment of the present invention. As shown in the figure, the cutting head is an isosceles triangle with a height of 60 mm and a base length of 40 mm. The material of the cutting head of the triangle is a steel plate with a thickness of 20 mm.

[0034] The handle is a steel pipe 3, the steel pipe material is DN32, and the length of the steel pipe is 1.5m.

[0035] Wherein: the center point of the bottom edge of the triangular cutting head 1 is welded and fixed to one end of the steel pipe, and the top of the corner corresponding to the bottom edge is provided with a groove 2 with a depth of 40mm, and the center line of the groove is on the same straight line as the axis of the steel pipe.

Embodiment 2

[0037] The manufacturing method of the tool that is used to cut off packing flat steel of the present invention, comprises the following steps:

[0038] a. Use a 20mm thick steel plate to make a triangle with a width of 40mm and a height of 60mm;

[0039] b. A groove with a width of 20mm is opened in the middle of the triangle, and the depth of the groove is 40mm, which is used as the cone head;

[0040] c. The bottom of the cone head is welded and fixed to the steel pipe of DN32, the steel pipe is 600mm long, and the tool for cutting the flat steel for packaging is completed.

Embodiment 3

[0042] The method of using the tool for cutting the packaged flat steel of the present invention: when cutting the packaged flat steel, make the triangular cutting head perpendicular to the flat steel, all the grooves go deep into the flat steel, lift the steel pipe upwards, and the packaged flat steel is quickly cut off.

[0043] The present invention has substantive features and significant technological progress. The tool and manufacturing method for cutting flat steel for packaging in the present invention has simple structure, convenient manufacture, and is convenient to carry. It can cut flat steel simply and quickly, save manpower and time, and improve work efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com