Automatic drilling, glue applying and screwing device

A technology of locking wire and gluing, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the inability of parameters such as personal ability and experience, drilling accuracy, torque, depth, glue amount and locking wire torque. Real-time measurement and control, assembly quality cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

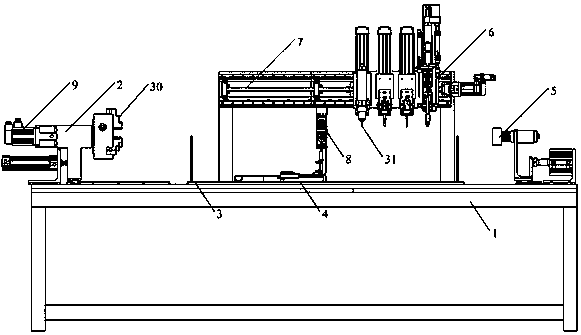

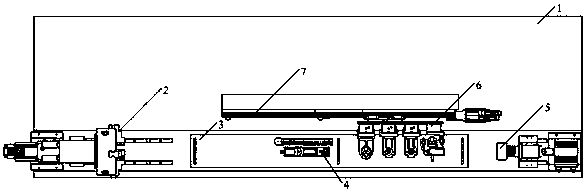

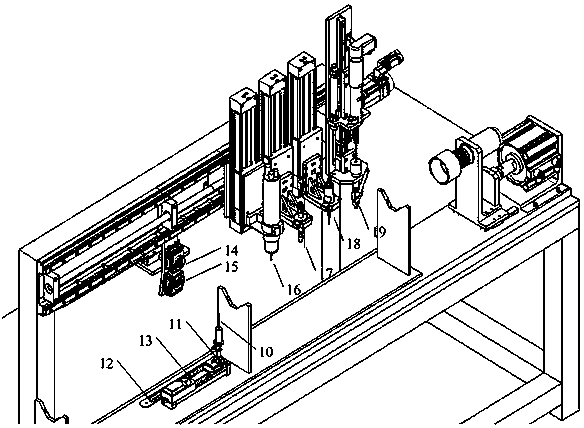

[0015] figure 1 , 2 In , 3, the main structure of the machine of the present invention includes: a working table 1, a rotating clamping mechanism 2, a supporting mechanism 3, a probe mechanism 4, a floating positioning mechanism 5, a drilling and locking thread assembly 6, a linear motion mechanism 7, and the like. The functions of each part of the main structure of the machine are as follows: the working surface 1 is used to fix and install various mechanism components; the rotating clamping mechanism 2 is used to clamp and fix the front end of the product and rotate it; the supporting mechanism 3 is used to support the middle part of the product; the probe rod mechanism 4 is used to confirm the positioning of the preset threaded hole of the product; the floating positioning mechanism 5 is used to press and fix the rear end of the product; the drilling and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com