Simple cutting device convenient for building heat-insulating plate

A cutting device and building insulation technology, applied in metal processing and other directions, can solve problems such as low work efficiency, failure to meet quality requirements, unevenness, etc., and achieve the effect of improving cutting efficiency, easy operation and use, and smooth cutting end surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

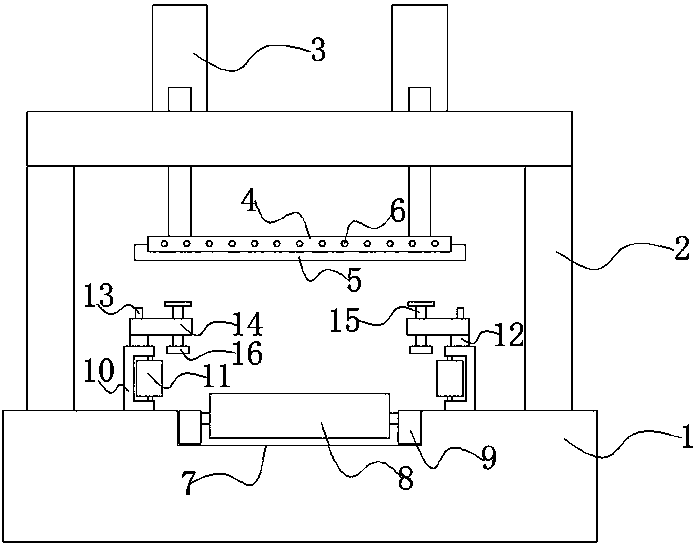

[0011] like figure 1 As shown, the present invention discloses a simple cutting device for building thermal insulation boards, comprising a base 1 and a cutting bracket 2, the base 1 is welded and fixedly installed with a gas cutting bracket 2, and the top end of the gas cutting bracket 2 is fixed Two groups of stamping cylinders 3 are installed, and the bottom ends of the two groups of stamping cylinders 3 are fixedly connected with the horizontal clamping plate 4, and the clamping plate 4 is locked with a punching knife plate 5 by fixing bolts 6, so as to facilitate The punching cylinder 3 drives the punching knife plate 5 to punch down the insulation board.

[0012] A guide roller 8 is installed under the punching knife plate 5, and the guide roller 8 is seated and installed in the installation groove 7 provided on the base, and the roller shaft ends on both sides of the guide roller 8 are rotated and installed. On the rotating seat 9, the top roller edge surface of the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com