Glass product cross-workshop transfer method

A technology for glass products, transfer methods, applied in the direction of conveyor objects, furnaces, lighting and heating equipment, etc., which can solve the problems of occupying ground space, glass plate damage, economic loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

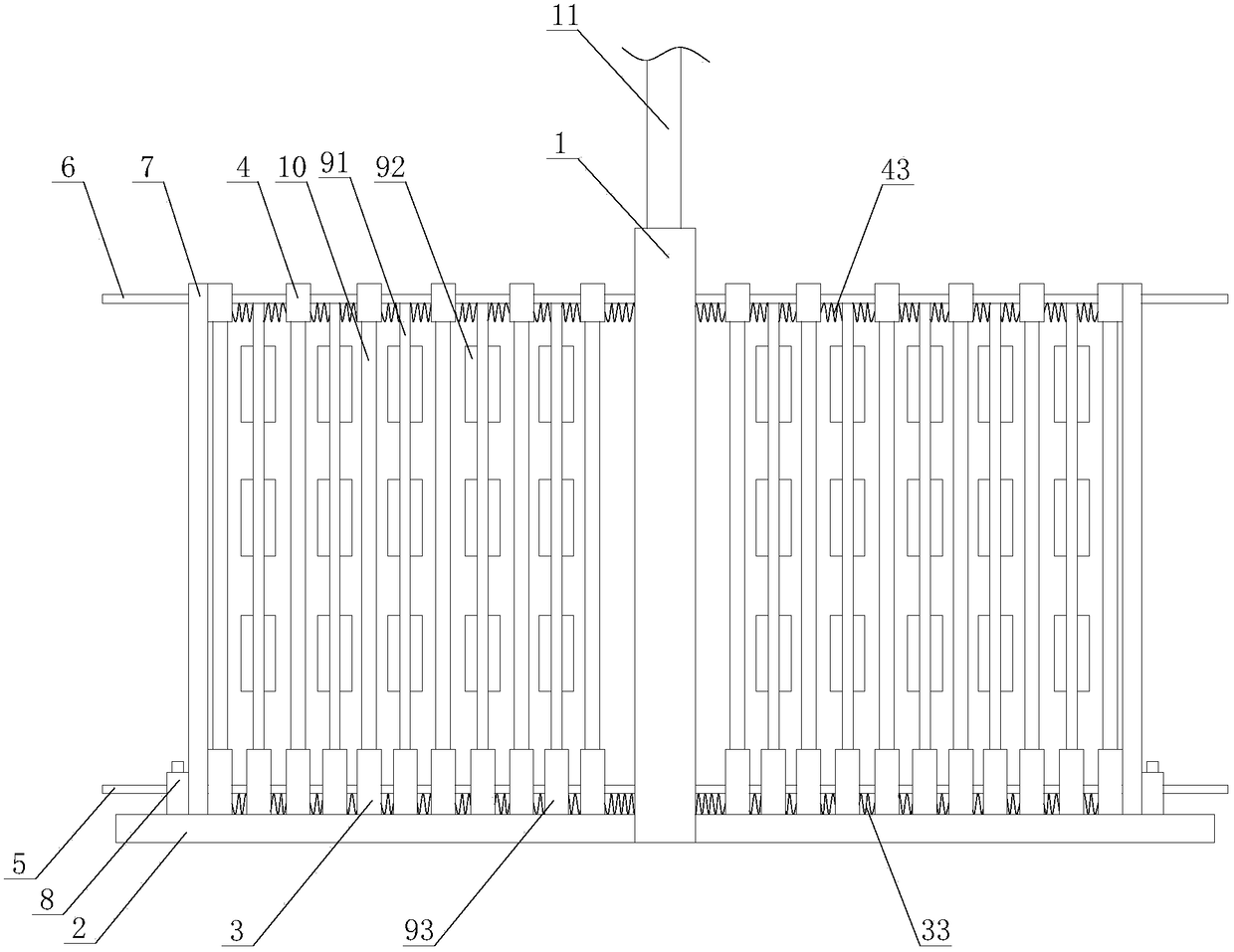

[0045] like Figure 1 to Figure 4 In the illustrated embodiment, the cross-workshop transfer method of glass products includes the following steps:

[0046] (A) Assemble the top fixing piece and the two bottom fixing pieces on the glass plate, attach the two bottom fixing pieces to the two right angles at the bottom of the glass plate, then install the first spring, and clamp the top fixing piece on the glass the top of the board;

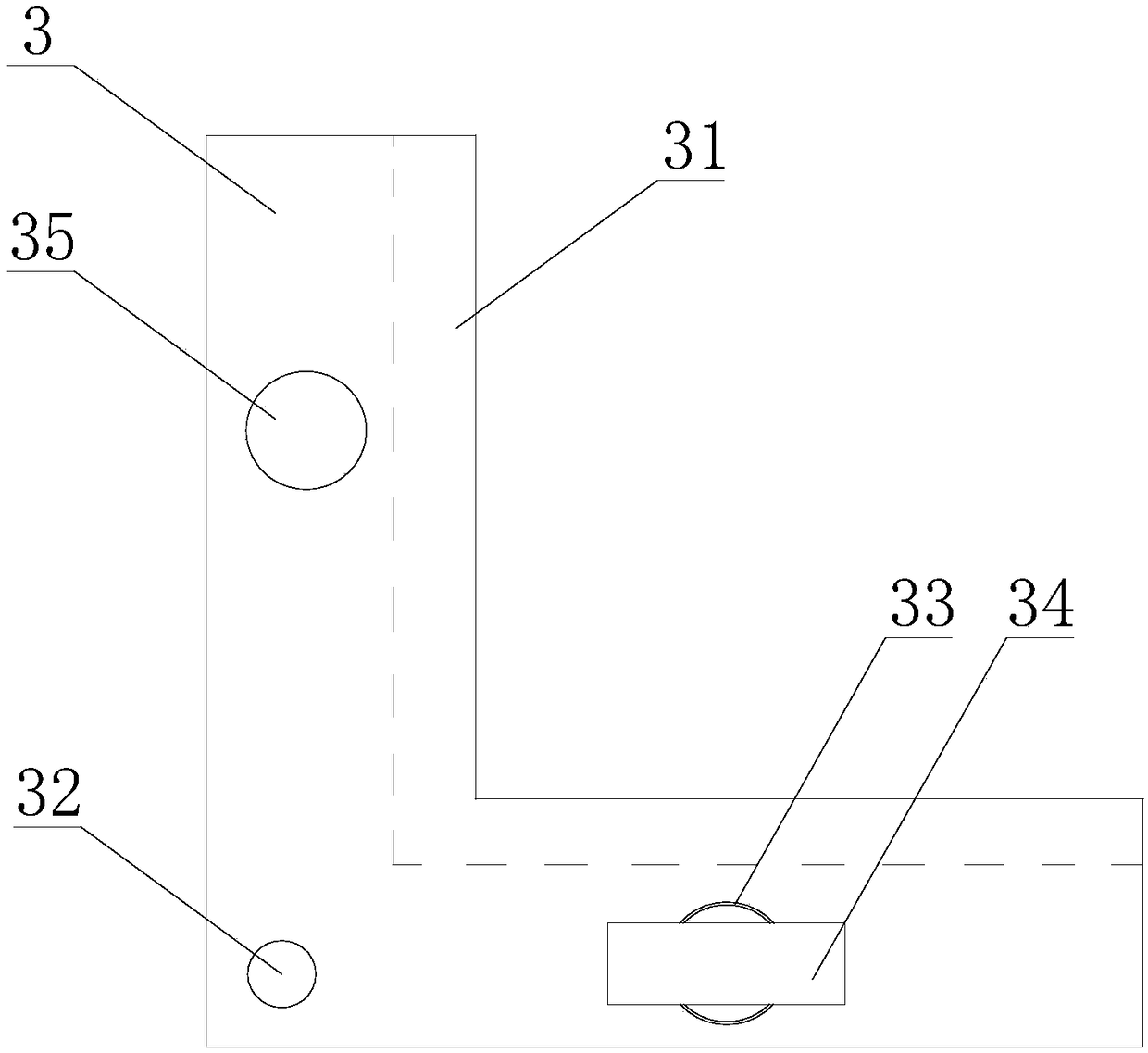

[0047] (B) Install the top fixing piece on the top guide rod, install the bottom fixing piece on the bottom guide rod, push the glass plate towards the hanging plate, set the top fixing piece on the top guide rod, and set the bottom fixing piece on the On the bottom guide bar, the top fixing piece and the two bottom fixing pieces limit the glass plate. At this time, the glass plate will not move relative to the top fixing piece or the bottom fixing piece. The glass plate, the bottom fixing piece and the top fixing piece constitute move together a...

Embodiment 2

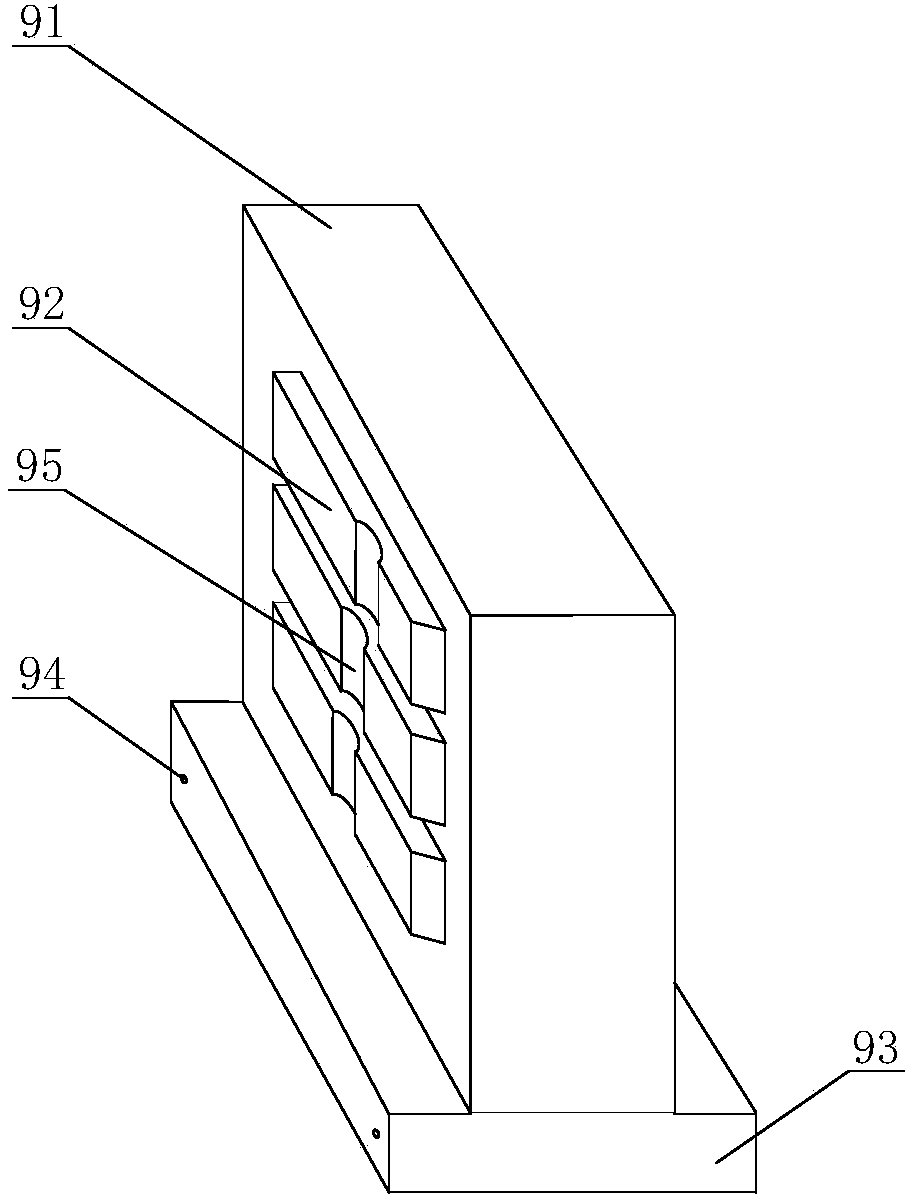

[0055] like figure 2 As shown, on the basis of Embodiment 1, the spoiler vane 92 of this embodiment is provided with a spoiler groove 95, and the spoiler groove 95 is a semi-cylindrical body. The above-mentioned design prevents the glass plate 10 from being damaged by the impact force of the water flow on the glass plate 10, and the cleaning effect is very good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com