Clamping device for chemical membrane optical element

A clamping device and optical element technology, applied in the direction of load hanging element, transportation and packaging, etc., can solve the problems of easy damage, no physical film wipeability, lack of self-healing ability, etc., to achieve reliable connection, The effect that the technical indicators are not reduced and the cleanliness is not polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

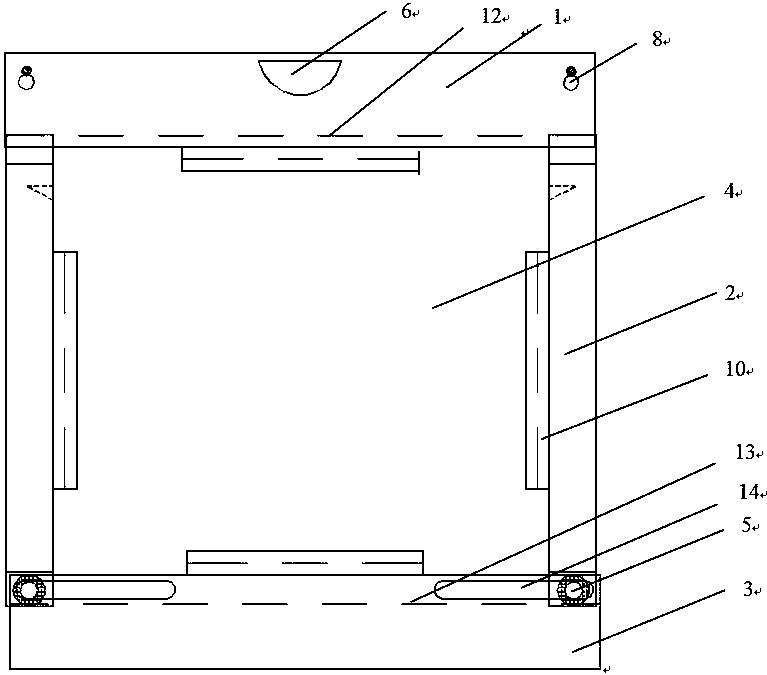

[0039] The assembly process of the optical element clamping device of the present invention is as follows:

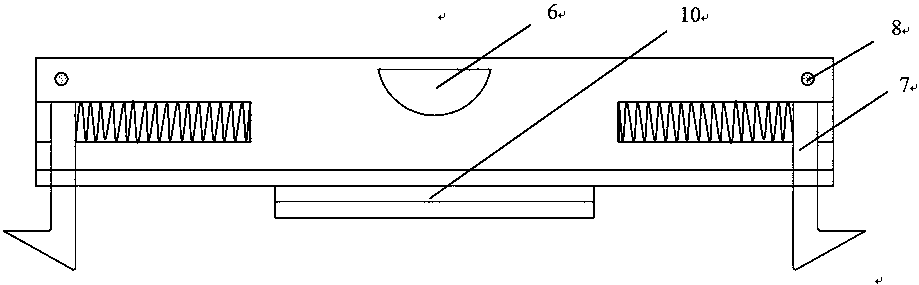

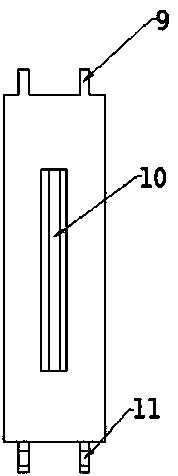

[0040] Place the chemical film optical element to be clamped in the U-shaped clamping groove of the load-bearing beam 3, and then move the clamping beam 2 along the sliding groove 13 of the load-bearing beam 3 according to the specific size of the chemical film optical element until The U-shaped clamping groove of the clamping beam 2 fits the chamfering edge of the chemical film optical element, and the load-bearing beam 3 is fixedly connected with the two clamping beams 2 through the positioning bolt 5; then the lifting beam 1 is placed on the exposed chemical film optical element On the side wall, turn off the adjustment switch 7 to fix the chemical film optical element in the clamping device, so as to ensure that the chemical film optical element does not move in the three-dimensional space. Then the sealing plate 4 is installed, and the loading and unloading of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com