A kind of preparation method of ammonium paratungstate

A technology of ammonium paratungstate and sodium tungstate, which is applied in the field of tungsten metallurgy, can solve the problems of small exchange volume of resin work, increased production cost, and difficult recycling, etc., and achieves the effects of low cost, easy handling, and reduced dilution water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

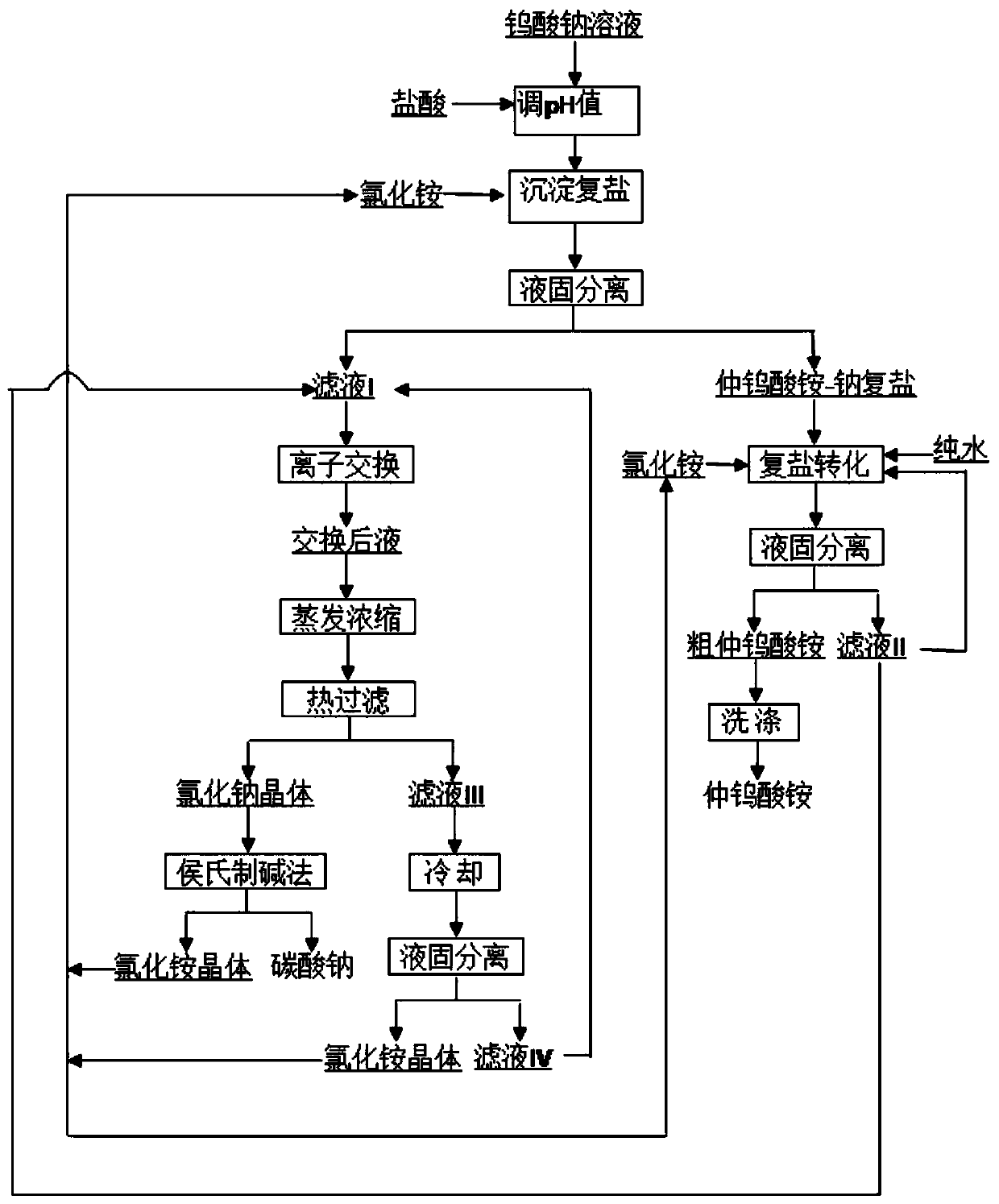

[0038] The invention provides a kind of preparation method of ammonium paratungstate, as figure 1 shown, including the following steps:

[0039] (1) Take 1000mL of 100g / L (WO 3 concentration) sodium tungstate solution, adjust the pH of the feed solution to 6.0 with a mass concentration of 35% hydrochloric acid, and then add solid NH 4 Cl (sodium tungstate and NH 4 The molar ratio of Cl is 1:4), stirred and reacted at 90°C for 0.5h and kept warm for 2h, obtained ammonium paratungstate-sodium double salt and filtrate I after solid-liquid separation, and the precipitation rate of ammonium paratungstate-sodium double salt was 98.3%;

[0040] (2) Take ammonium paratungstate-sodium double salt product as raw material, take 100g of the double salt product in a beaker, and then add 400mL of 28% NH 4Cl solution, converted at a constant temperature of 85°C for 20min, filtered to obtain crude ammonium paratungstate and filtrate II, with 3% NH 4 The crude ammonium paratungstate is was...

Embodiment 2

[0045] The invention provides a kind of preparation method of ammonium paratungstate, as figure 1 shown, including the following steps:

[0046] (1) Take 1000mL of 300g / L (WO 3 concentration) sodium tungstate solution, adjust the pH of the feed solution to 7.2 with a mass concentration of 30% hydrochloric acid, and then add solid NH 4 Cl (sodium tungstate and NH 4 The molar ratio of Cl is 1:3), stirred and reacted at 60°C for 1.0h and kept warm for 4h, and obtained ammonium paratungstate-sodium double salt and filtrate I after solid-liquid separation, and the precipitation rate of ammonium paratungstate-sodium double salt was 98.8%;

[0047] (2) Take ammonium paratungstate-sodium double salt product as raw material, take 100g of the double salt product in a beaker, and then add 600mL of 15% NH 4 Cl solution, converted at a constant temperature of 95°C for 40min, and filtered to obtain crude ammonium paratungstate and filtrate II, with 5% NH 4 The crude ammonium paratungsta...

Embodiment 3

[0052] The invention provides a kind of preparation method of ammonium paratungstate, as figure 1 shown, including the following steps:

[0053] (1) Take 1000mL of 500g / L (WO 3 concentration) sodium tungstate solution, adjust the pH of the feed solution to 7.5 with a mass concentration of 20% hydrochloric acid, and then add solid NH 4 Cl (sodium tungstate and NH 4 The molar ratio of Cl is 1:1.6), stirred and reacted at 95°C for 2.0 hours and kept warm for 8 hours, and obtained ammonium paratungstate-sodium double salt and filtrate I after solid-liquid separation, and the precipitation rate of ammonium paratungstate-sodium double salt was 97.6%;

[0054] (2) Using ammonium paratungstate-sodium double salt product as raw material, take 100g of the double salt product in a beaker, and then add 500mL of 25% NH 4 Cl solution, converted at a constant temperature of 90°C for 30min, and filtered to obtain crude ammonium paratungstate and filtrate II, with 5% NH 4 The crude ammoniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com