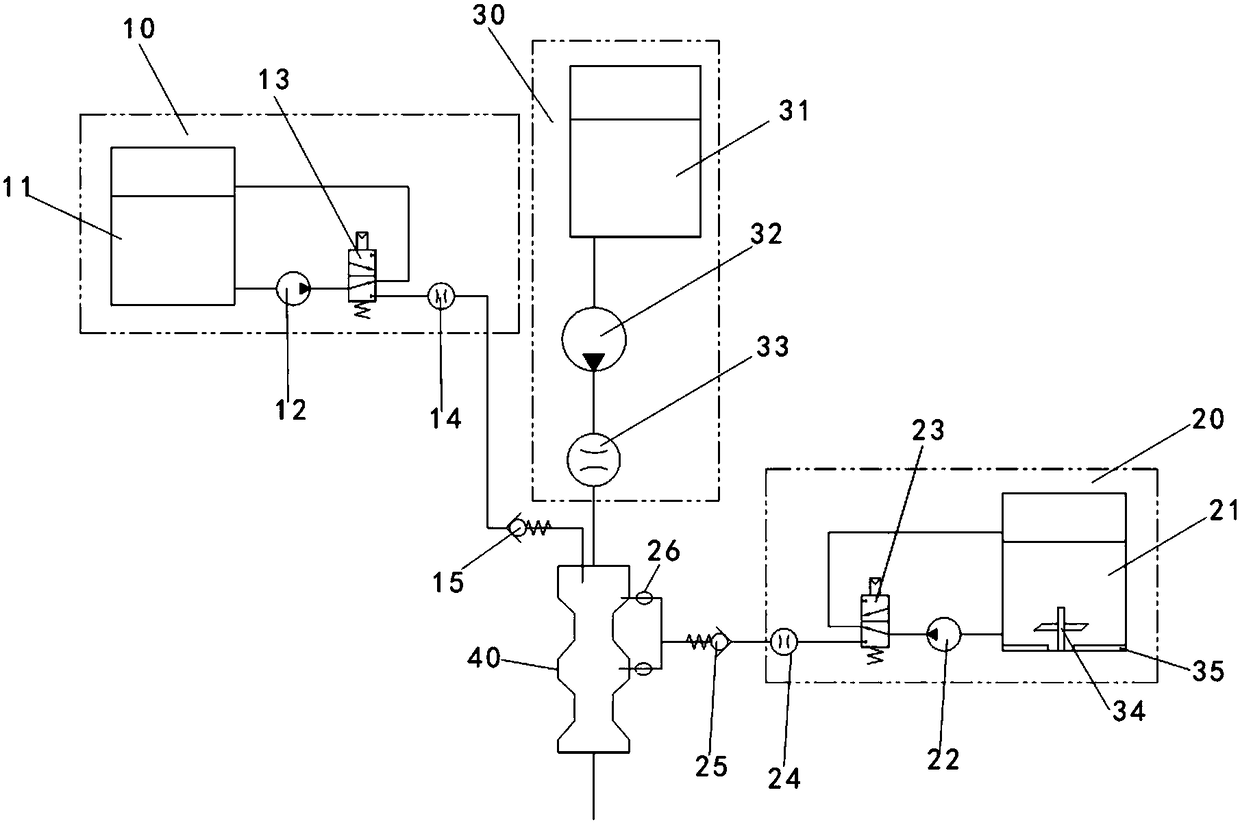

Asphalt foam warm mixing system and asphalt foam warm mixing process

An asphalt and foam technology, which is applied in the field of asphalt foam warm mix system and foam warm mix process, can solve the problem that the addition ratio of foam stabilizer cannot be quantitatively controlled, and achieve the effect of excellent effect and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

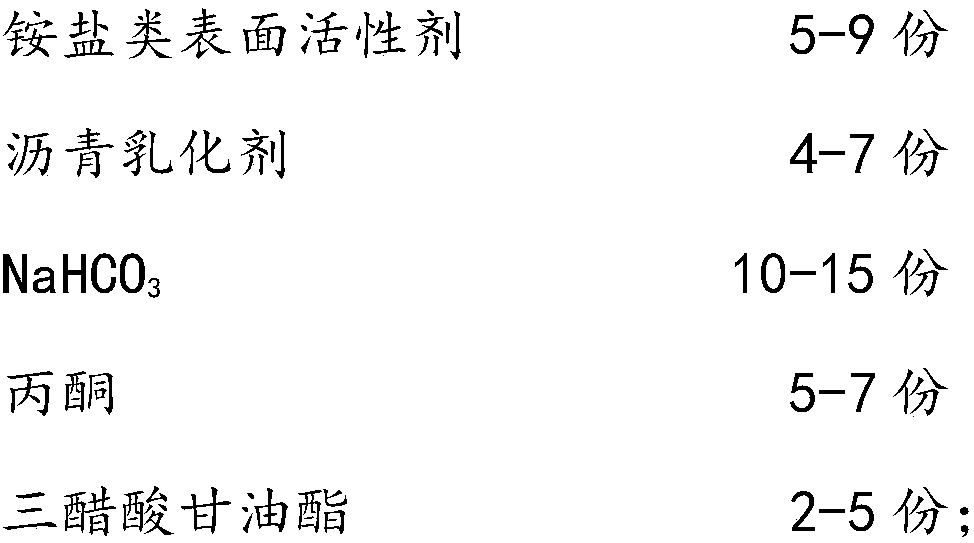

[0068] 1. Preparation of foam stabilizer:

[0069] 4 parts of 1-N-hydroxyethyl-2-alkyl imidazoline quaternary ammonium salt, 3 parts of cracked asphalt emulsifier, 11 parts of NaHCO 3 Powder, 5 parts of acetone and 3 parts of triacetin are stirred and mixed, and put into the foam stabilizer storage tank;

[0070] 2. Asphalt foam warm mixing process

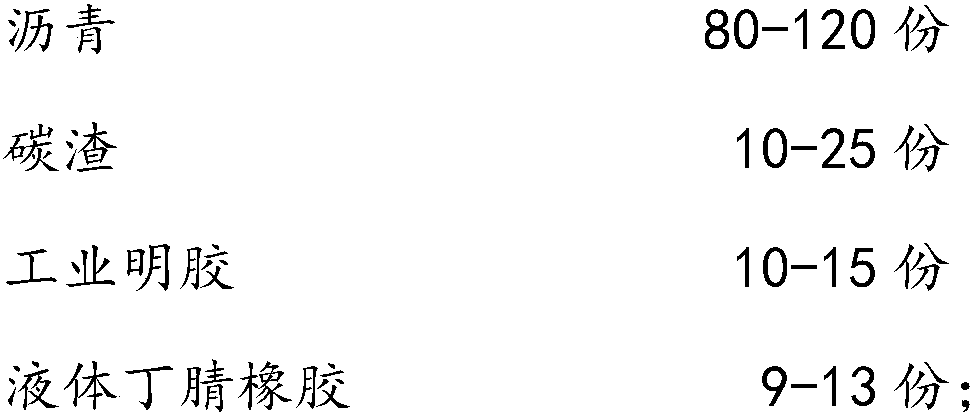

[0071] S100. Add 85 parts of pitch and carbon residue to the pitch tank, and stir at 100°C for 35 minutes;

[0072] S200, continue to stir the asphalt in the asphalt tank, heat the temperature to 130°C, add 10 parts of industrial gelatin and 9 parts of liquid nitrile rubber into the asphalt tank, and stir for 30 minutes to form a mixture;

[0073] S300. After passing the mixture in the asphalt tank into the foaming pipe, add water with 0.9% of the weight of the mixture from the water tank to the foaming pipe, and add a foam stabilizer with 0.5% of the weight of the asphalt within 5s to perform mixing and foaming;

[0074] S400,...

Embodiment 2

[0076] 1. Preparation of foam stabilizer:

[0077] 9 parts of 1-N-hydroxyethyl-2-alkyl imidazoline quaternary ammonium salt, 7 parts of cracked asphalt emulsifier, 15 parts of NaHCO 3 Powder, after stirring and mixing 7 parts of acetone and 5 parts of triacetin, put it in the foam stabilizer storage tank;

[0078] 2. Asphalt foam warm mixing process

[0079] S100. Add 120 parts of pitch and carbon residue to the pitch tank, and stir at 110°C for 60 minutes;

[0080] S200, continue to stir the asphalt in the asphalt tank, heat the temperature to 140°C, add 15 parts of industrial gelatin and 13 parts of liquid nitrile rubber into the asphalt tank, and stir for 35 minutes to form a mixture;

[0081] S300. After passing the mixture in the asphalt tank into the foaming tube, stir water and carbon powder according to the weight ratio of 100:1 to form a turbid liquid, add 1% of the mixture weight turbid liquid from the water tank to the foaming tube, and Add a foam stabilizer of 1...

Embodiment 3

[0084] 1. Preparation of foam stabilizer:

[0085] 8 parts of 1-N-hydroxyethyl-2-alkyl imidazoline quaternary ammonium salt, 5 parts of cracked asphalt emulsifier, 12 parts of NaHCO 3 Powder, after stirring and mixing 6 parts of acetone and 4 parts of glycerol triacetate, put into the foam stabilizer storage tank;

[0086] 2. Asphalt foam warm mixing process

[0087] S100. Add 90 parts of pitch and carbon residue to the pitch tank, and stir at 110°C for 65 minutes;

[0088] S200, continue to stir the asphalt in the asphalt tank, heat the temperature to 140°C, add 12 parts of industrial gelatin and 10 parts of liquid nitrile rubber into the asphalt tank, and stir for 40 minutes to form a mixture;

[0089] S300. After passing the mixture in the asphalt tank into the foaming tube, stir water and carbon powder according to the weight ratio of 100:1 to form a turbid liquid, add 1% of the mixture weight turbid liquid from the water tank to the foaming tube, and Add a foam stabilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com