Metro shield tunnel extension steel ring initial construction method

A technology for subway shield tunneling and construction methods, which is applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of delaying the starting progress of shield tunneling machines, increasing the risk of shield tunneling starting, and affecting the construction environment of workers. Achieve the effect of eliminating instability, shortening the construction period, and avoiding construction environment pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

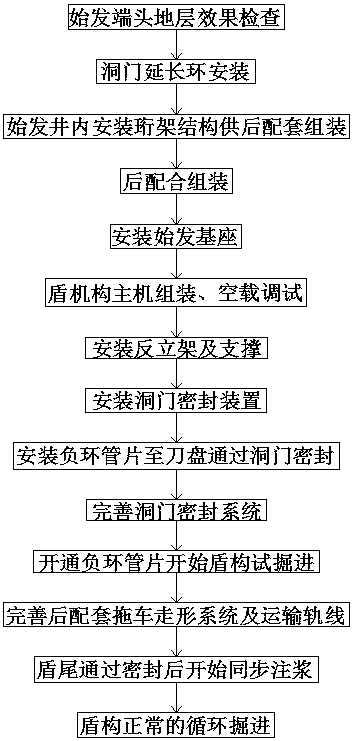

[0038] Such as Figure 1-Figure 5 As shown, a subway shield tunnel extension steel ring starting construction method comprises the following steps:

[0039] a. Inspection of the stratum effect at the starting end. Before the start of shield tunneling, 9 horizontal door probe holes 7 should be drilled along the reinforcement body within the door circle. The depth of the door probe holes 7 is the longitudinal direction of the end reinforcement. Half of the length, observe the water seepage;

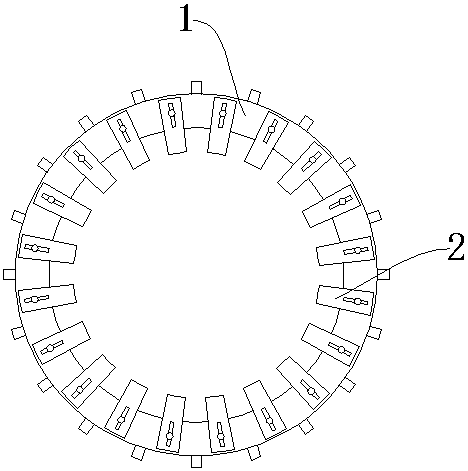

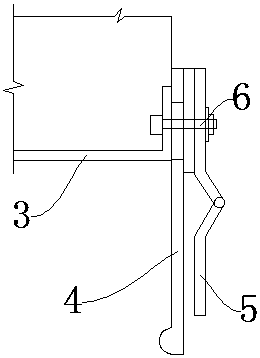

[0040] b. The door extension ring 1 is installed, and one end of the door extension ring 1 is connected to the door steel ring with M20 bolts;

[0041] c. Install the truss structure in the originating shaft for subsequent supporting assembly, retest the departure section of the main body of the station, measure the actual deviation and start installing the truss structure;

[0042] d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com