Centrifugal pump impeller

A centrifugal pump impeller and impeller technology, applied to pumps, pump components, non-variable pumps, etc., can solve problems such as difficult welding and slow water flow, and achieve the effects of improving connection strength, facilitating welding, and reducing the impact of flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

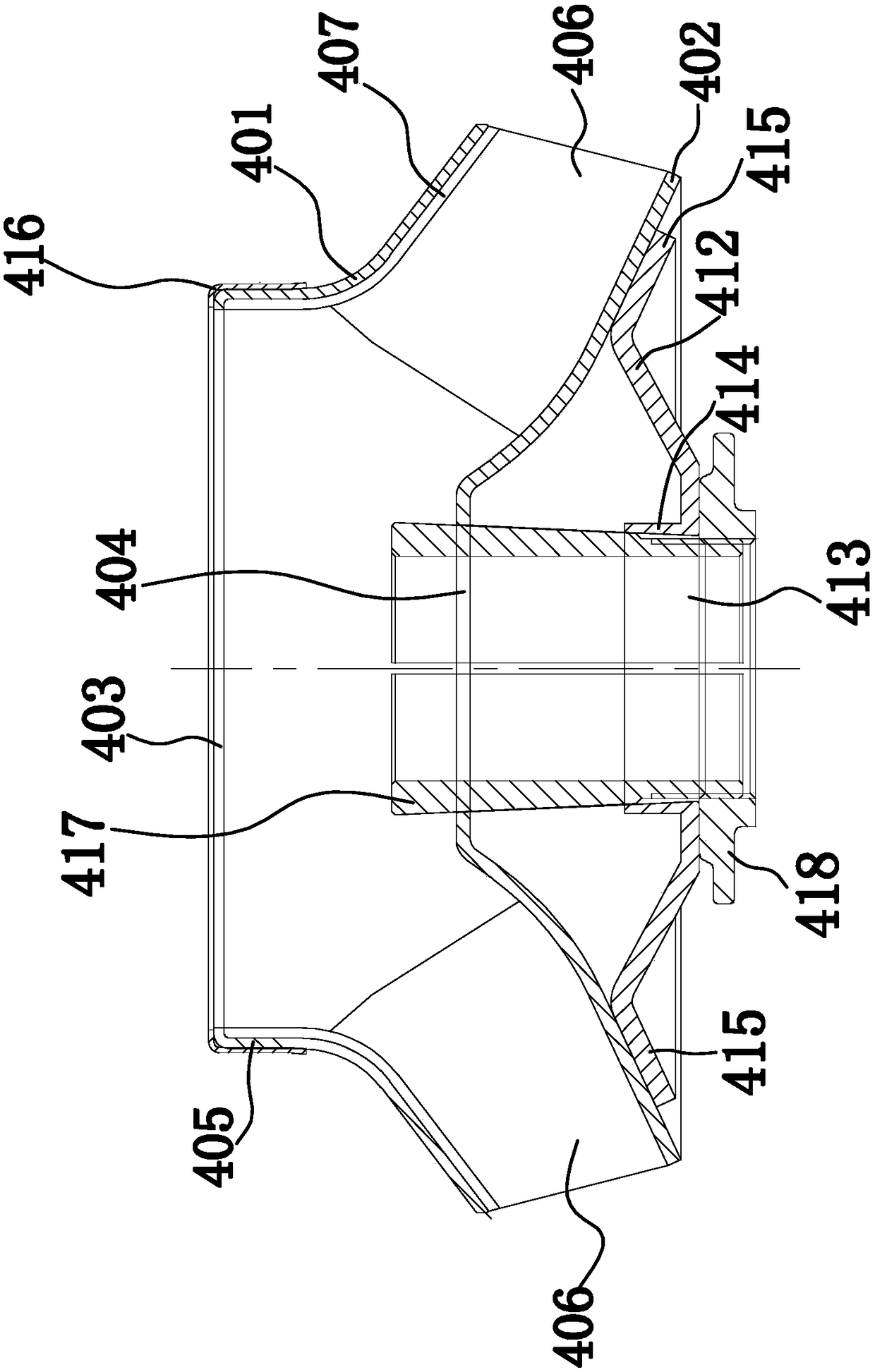

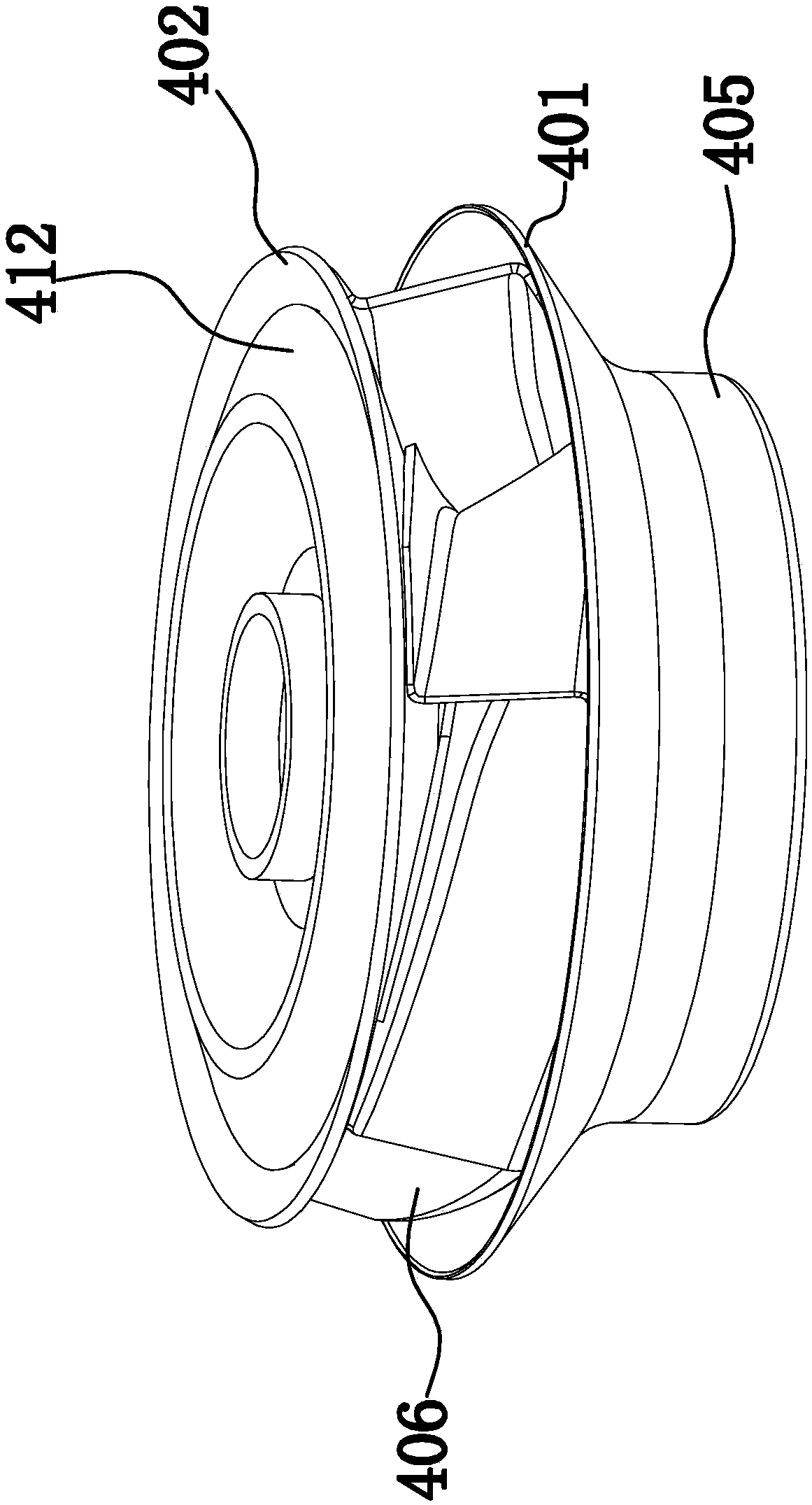

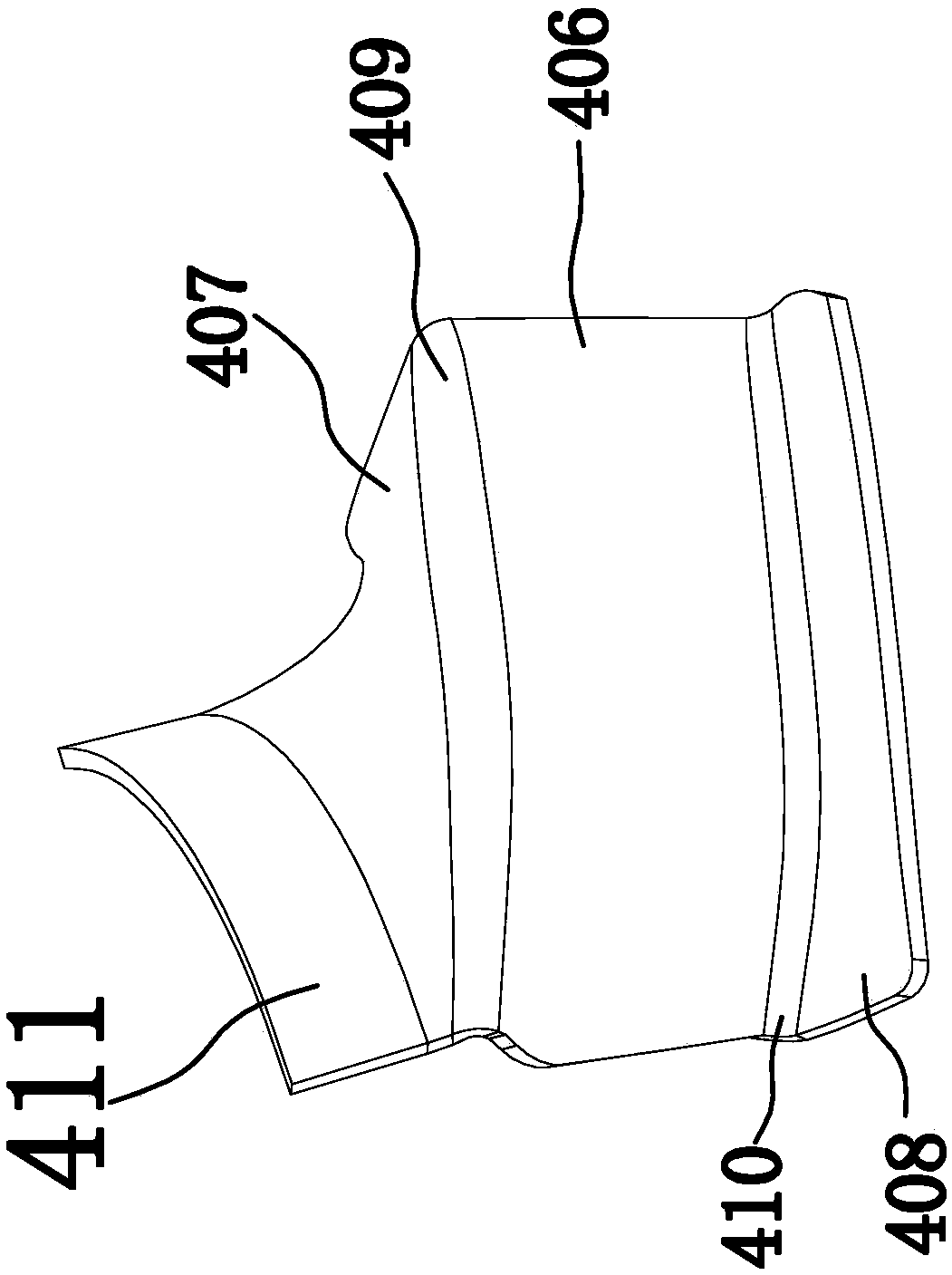

[0024] Such as Figures 1 to 6 As shown, the impeller of the centrifugal pump includes a first impeller cover plate 401 and a second impeller cover plate 402 arranged in sequence along the same axial direction. An impeller through hole 403, the middle part of the second impeller cover plate 402 is provided with a second impeller through hole 404 for the external pump shaft 101 to pass through, between the first impeller cover plate 401 and the second impeller cover plate 402 there is a The coaxial impeller fixing member for fixing the impeller on the pump shaft 101 and keeping the impeller and the pump shaft 101 rotating synchronously is characterized in that: the first impeller cover plate 401 is located in the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com