Method for predicting industrial sewage inflow based on ARIMA model

A technology for industrial sewage and water inflow, applied in forecasting, CAD numerical modeling, energy industry, etc., can solve problems such as large fluctuation range, uncontrollable influent load, and strong mutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

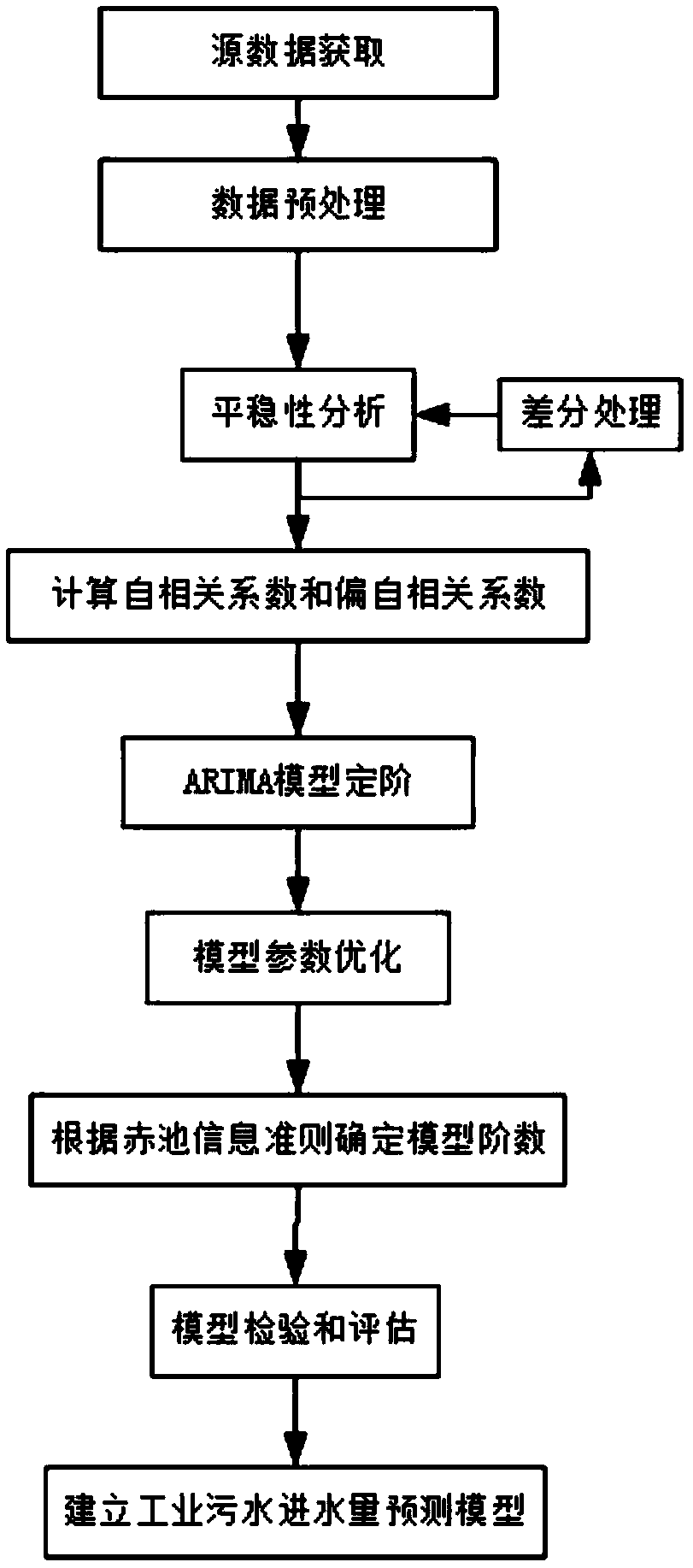

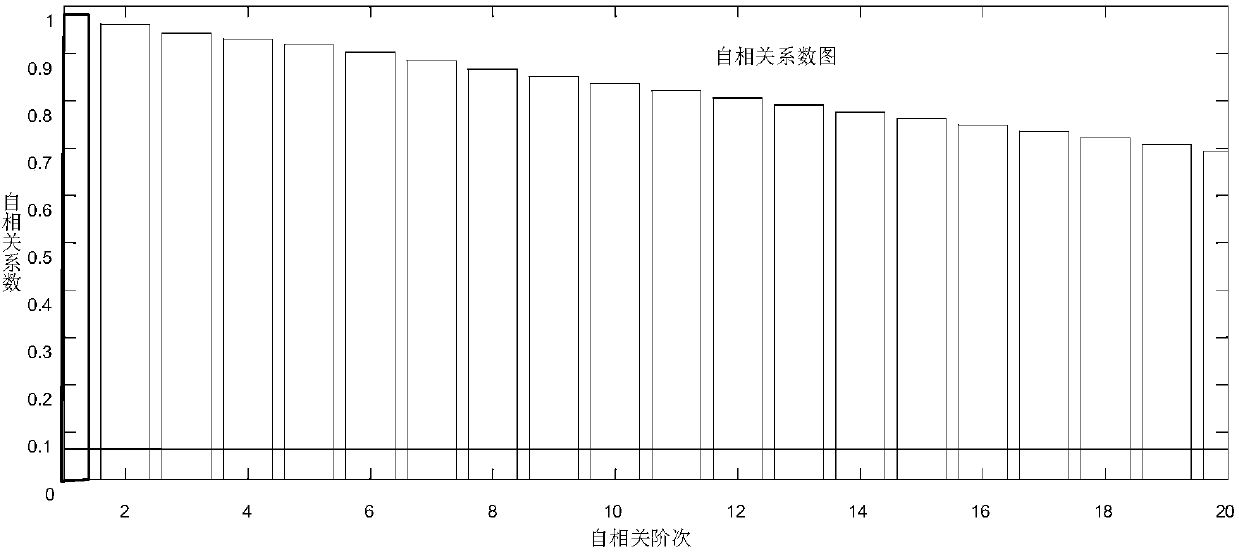

[0072] Such as figure 1 As shown, a prediction method of industrial sewage inflow based on ARIMA model includes the following steps:

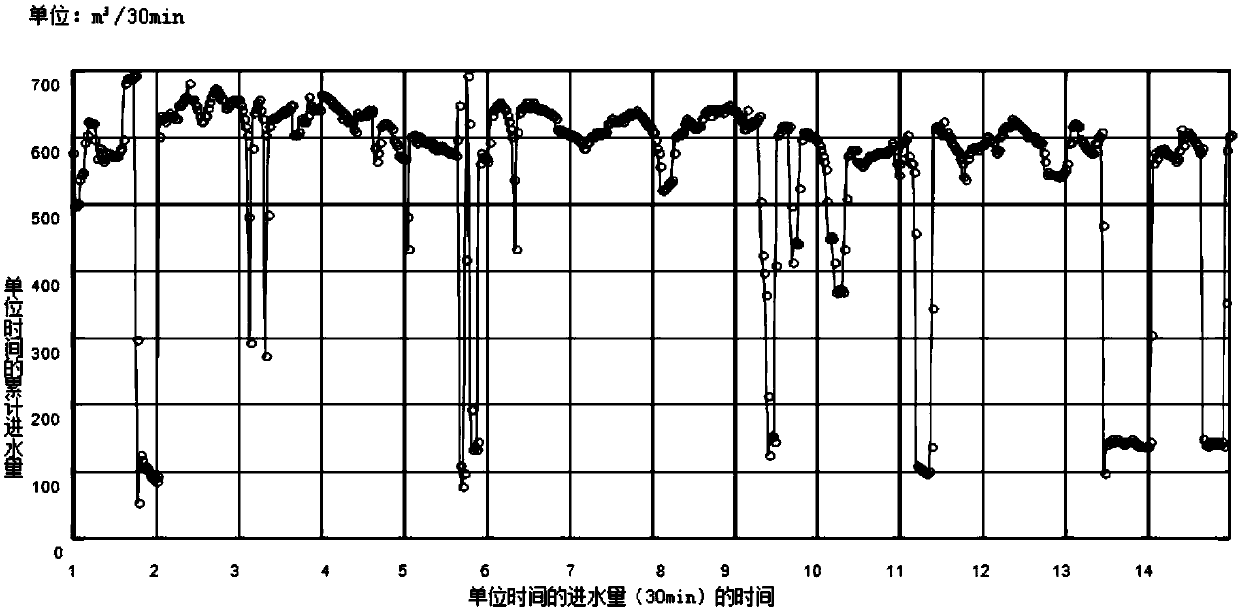

[0073] S1. Considering that the main influencing factor of the water inflow is the sudden discharge of industrial sewage or natural precipitation, the reason why these data cannot be obtained at present is that the water inflow is only based on the characteristics of the data sequence itself, so the sewage inflow itself is selected as the input variable; the sewage is obtained The original time series data of water inflow, and conduct data quality analysis to check whether there are dirty data and data that cannot be directly analyzed in the original time series data;

[0074] The dirty data includes missing values, outliers, and data containing special characters; the outliers are initially judged by using a univariate scatter diagram, and then the outliers are checked using the statistical 3σ method;

[0075] In this embodiment, data feature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com