A tubeless liquid cooling system

A liquid-cooled heat dissipation and heat dissipation device technology, applied in cooling/ventilation/heating transformation, tubular elements, indirect heat exchangers, etc., can solve the problems of inconvenient installation and operation, poor installation flexibility, complex overall design, etc., and achieve flexible installation and use. Convenience and space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the purpose, technical solutions and advantages of the present invention clearer, the various embodiments to be described below will refer to the corresponding drawings, and these drawings constitute a part of the embodiments, which describe various possible implementations of the present invention. kind of embodiment. It is to be understood that other embodiments may be utilized or structural and functional modifications may be made to the embodiments set forth herein without departing from the scope and spirit of the present invention.

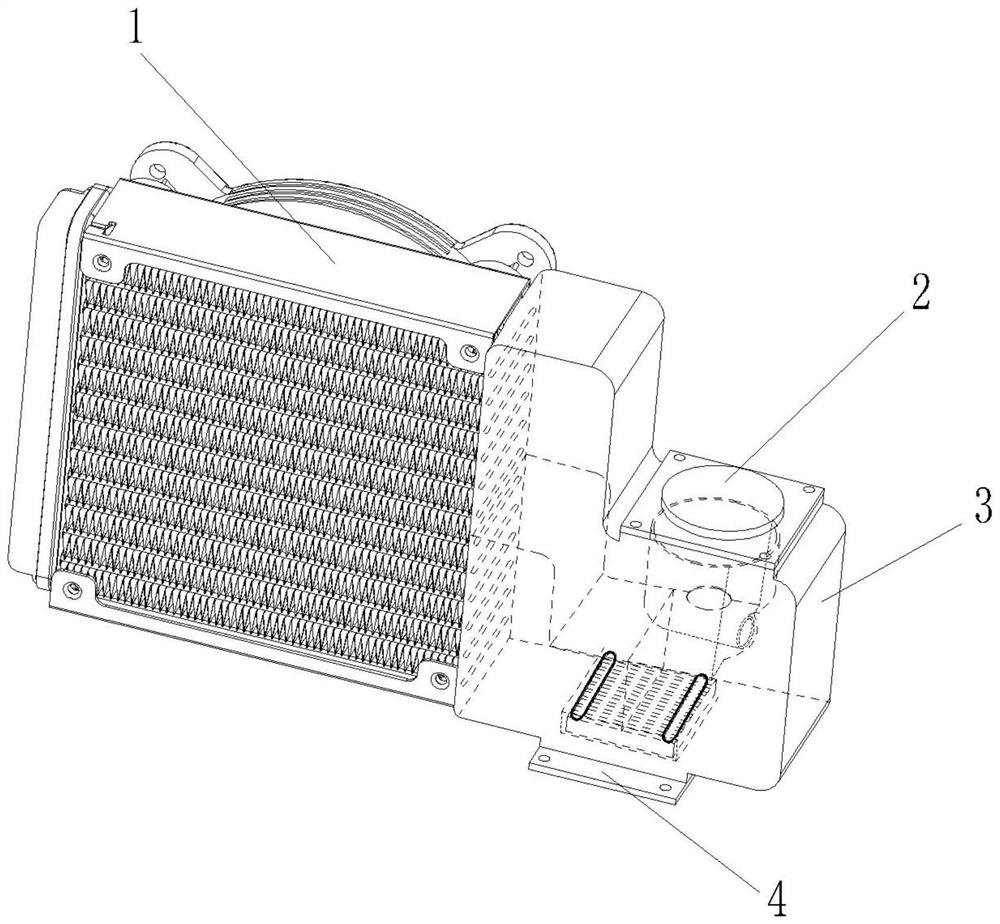

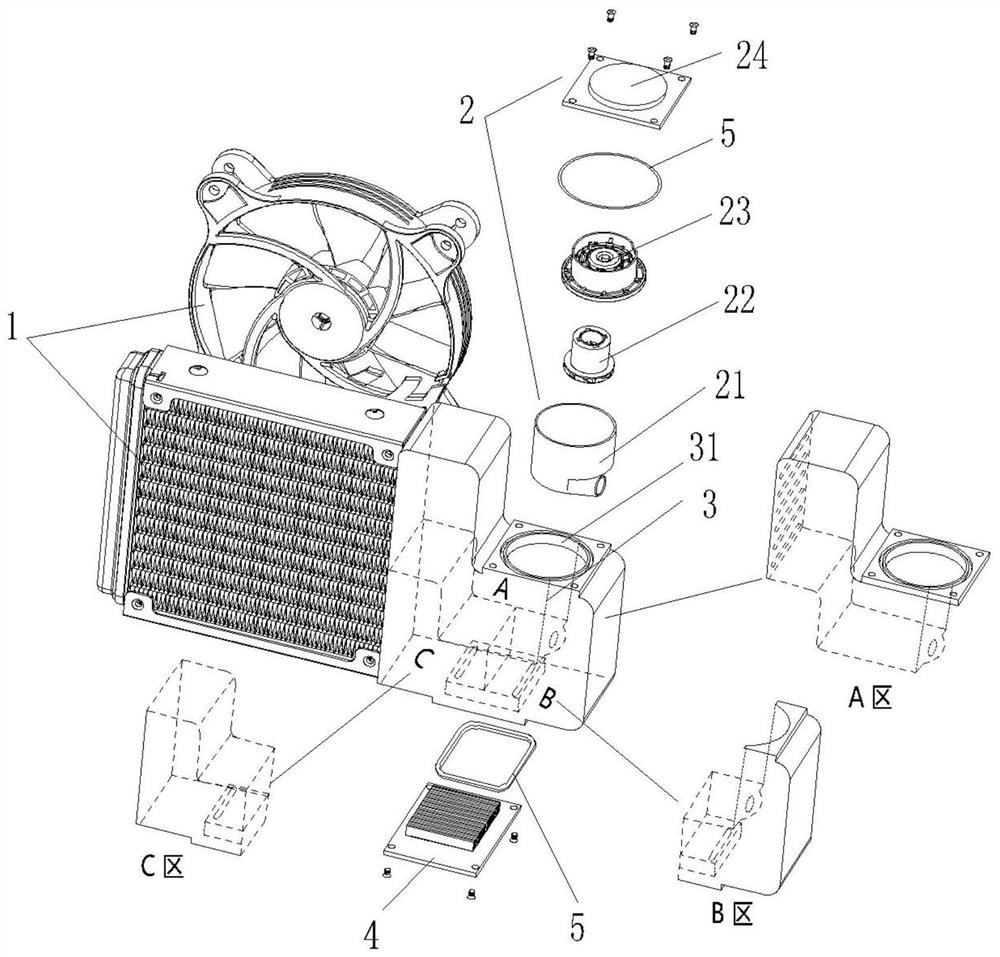

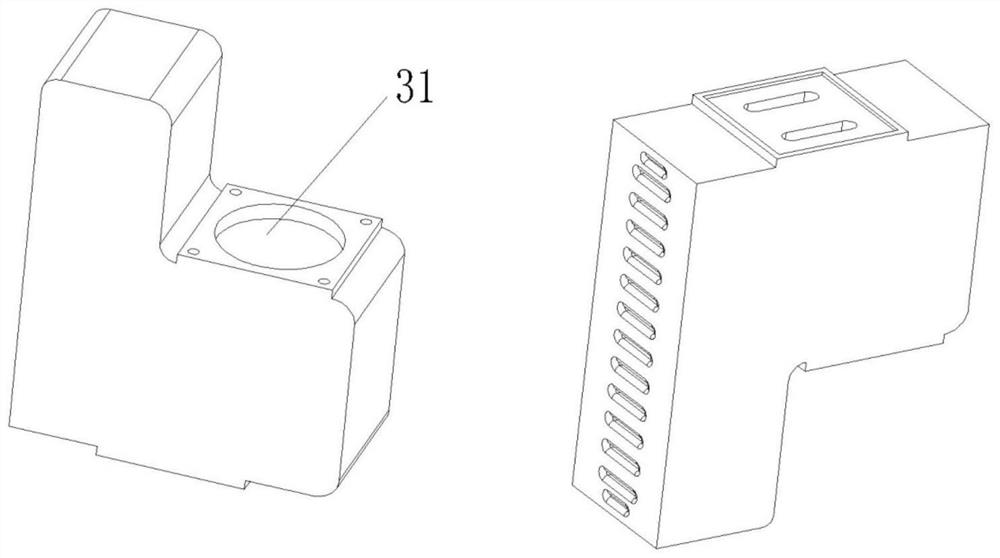

[0047] refer to Figure 1 to Figure 3As shown, a tubeless liquid-cooled heat dissipation system of the present invention includes a heat dissipation device 1, a pumping device 2, a water tank 3, and a heat absorbing device 4. The pumping device 2, the heat absorbing device 4, the heat sink 1 and the water tank 3. It is integrated and connected in a pipeless manner, that is, the connecting pipes between the parts are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com