Amino acid self-thickening composition, system and use thereof

An amino acid, self-thickening technology, applied in the field of daily chemicals, can solve the problems of easy to become jelly-like and limited thickening ability, and achieve the effects of mild surface activity, excellent thickening performance, and excellent low-temperature non-jelly performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

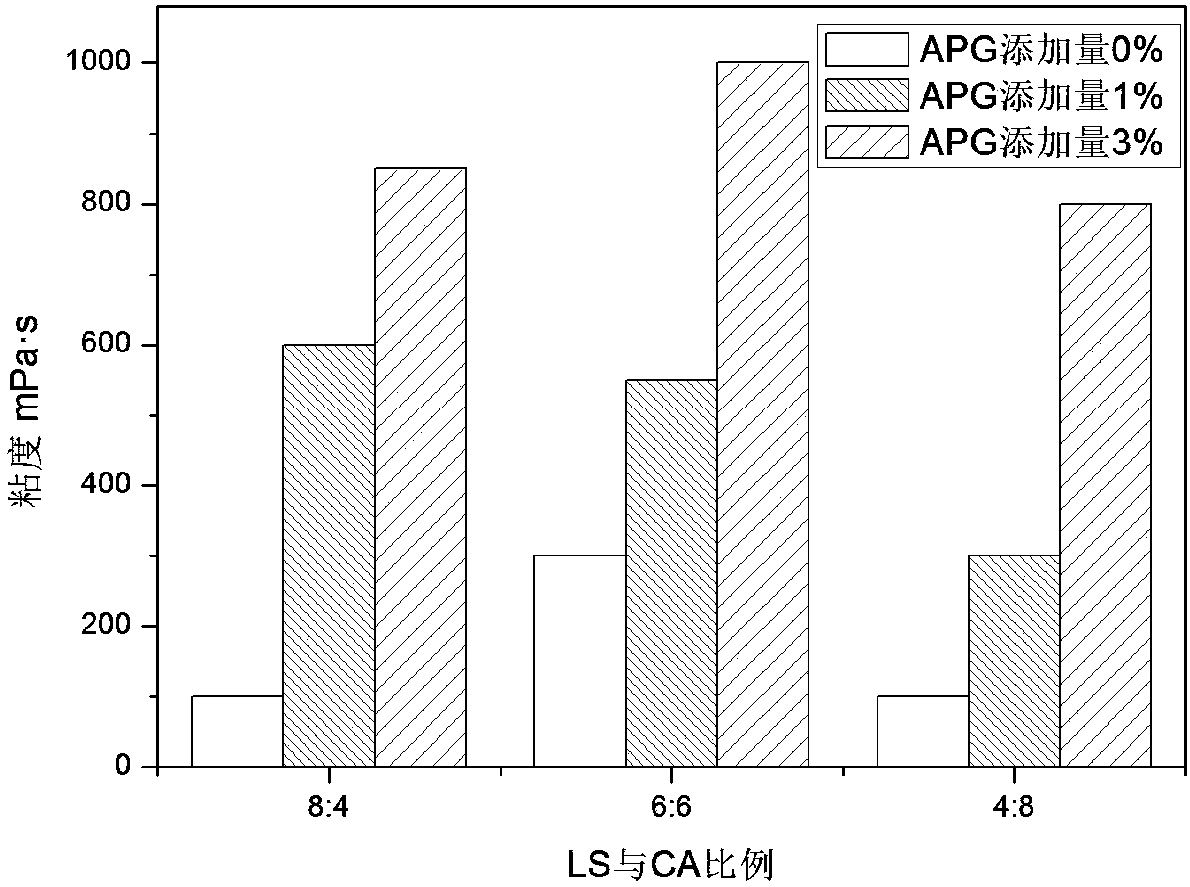

[0029] This example investigates the compounding properties of sodium lauroyl sarcosinate (LS), sodium cocoamidopropionate (CA), and alkyl glycosides (C12-C14APG).

[0030] Accurately weigh a certain quality of sodium lauroyl sarcosinate, sodium cocoamidopropionate, alkyl glucoside, deionized water, citric acid, heat in a water bath at 45°C, stir evenly, seal it and put it in a 25°C thermostat for standing After 24 hours, measure the pH5.2-5.8 and viscosity after taking it out and observe the appearance of the system.

[0031] The addition amount (percentage by weight) of sodium lauroyl sarcosinate, sodium cocoamidopropionate and alkyl glucoside is respectively:

[0032] 8%:4%:0%; 8%:4%:1%; 8%:4%:3%; 6%:6%:0%; 6%:6%:1%; 6%:6% :3%; 4%:8%:0%; 4%:8%:1%; 4%:8%:3%;

[0033] Its performance data can be found in the appendix figure 1 .

Embodiment 2

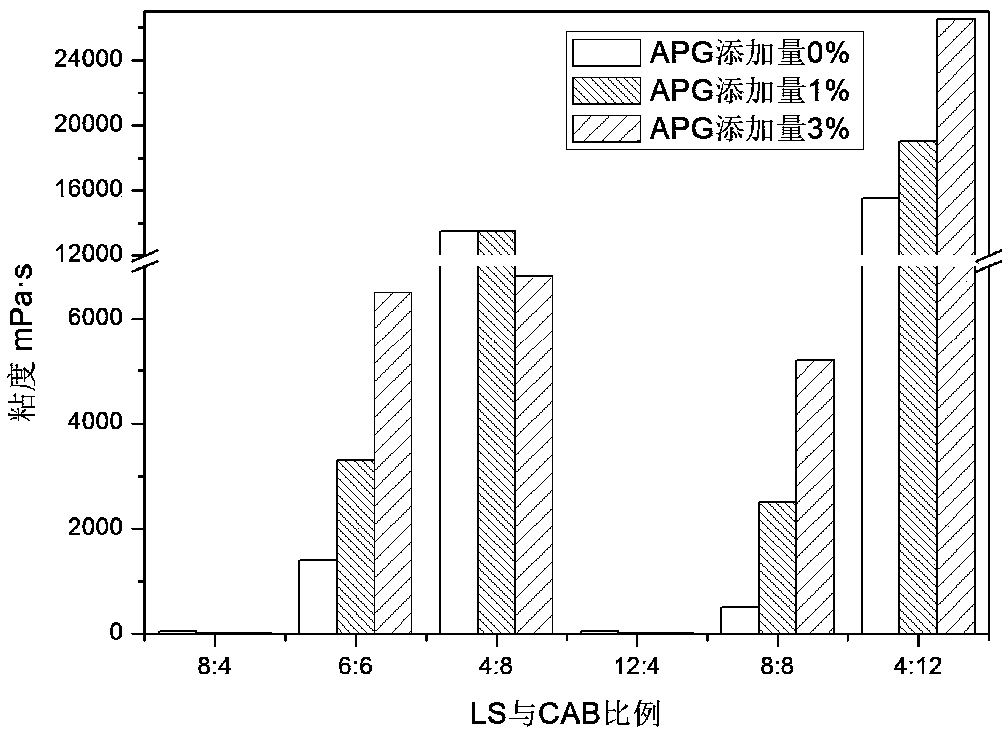

[0035] This example investigates the compounding properties of sodium lauroyl sarcosinate (LS), cocamidopropyl betaine (CAB), and alkyl glycosides (C12-C14APG).

[0036] Accurately weigh a certain quality of sodium lauroyl sarcosinate, cocamidopropyl betaine, alkyl glucoside, deionized water, citric acid, heat in a water bath at 45°C, stir evenly, seal it and put it in a 25°C thermostat for standing After 24 hours, measure the pH5.2-5.8 and viscosity after taking it out and observe the appearance of the system.

[0037] The addition (percentage by weight) of sodium lauroyl sarcosinate, cocamidopropyl betaine, and alkyl glucoside is respectively: 8%: 4%: 0%; 8%: 4%: 1%; 8%: 4% %:3%;6%:6%:0%;6%:6%:1%;6%:6%:3%;4%:8%:0%;4%:8%:1%; 4%:8%:3%; 12%:4%:0%; 12%:4%:1%; 12%:4%:3%; 8%:8%:0%; 8%:8% :1%;8%:8%:3%;4%:12%:0%;4%:12%:1%;4%:12%:3%;

[0038] Its performance data can be found in the appendix figure 2 .

Embodiment 3

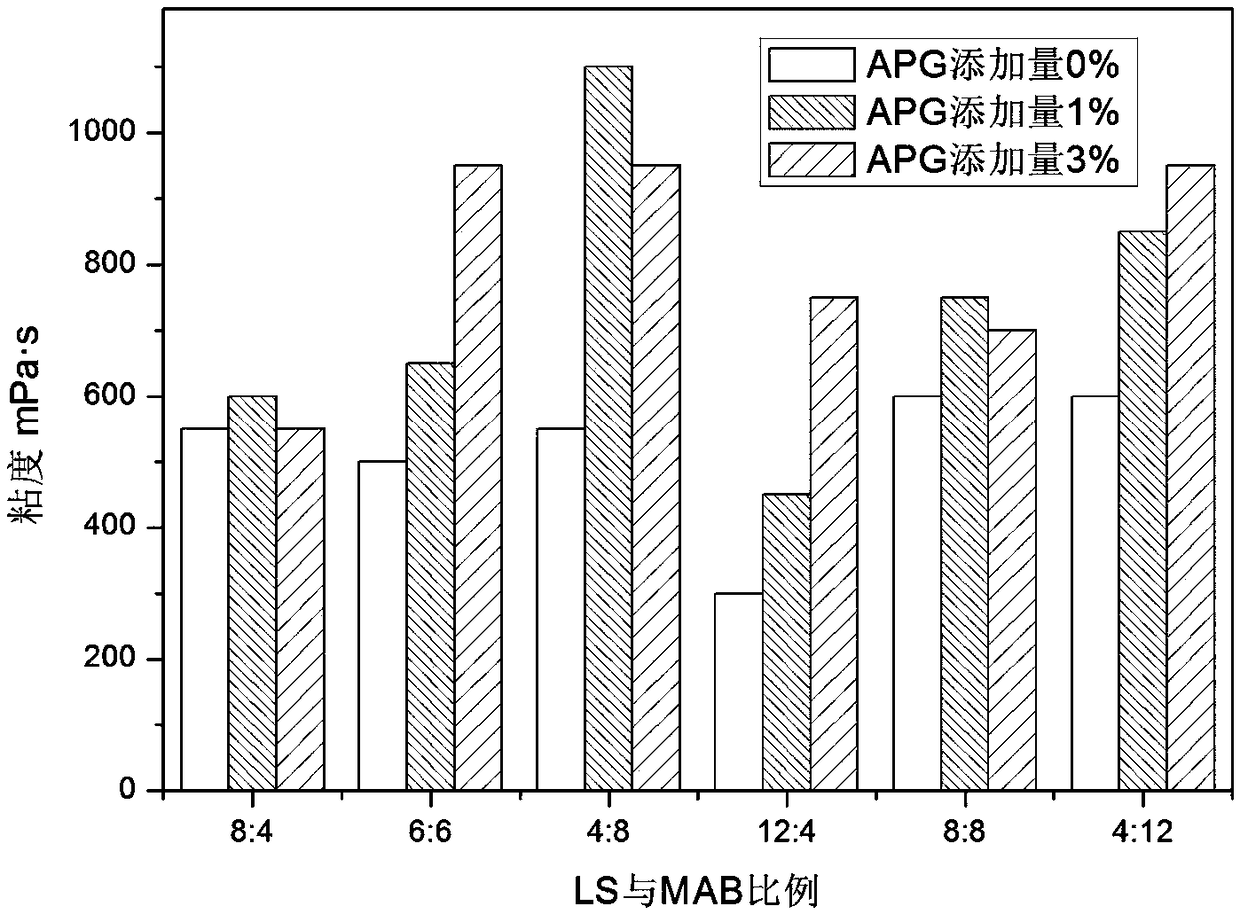

[0040] This example investigates the compounding properties of sodium lauroyl sarcosinate (LS), disodium cocoamphodiacetate (MAB), and alkyl glycosides (C12-C14APG).

[0041]Accurately weigh a certain quality of sodium lauroyl sarcosinate, disodium cocoamphodiacetate, alkyl glucoside, deionized water, citric acid, heat in a water bath at 45°C, stir evenly, seal and place in a 25°C incubator Let it stand for 24 hours, take it out, measure the pH5.2-5.8 and viscosity and observe the appearance of the system.

[0042] The addition amounts (percentage by weight) of sodium lauroyl sarcosinate, disodium cocoamphodiacetate, and alkyl glycosides are respectively: 8%: 4%: 0%; 8%: 4%: 1%; 8% :4%:3%;6%:6%:0%;6%:6%:1%;6%:6%:3%;4%:8%:0%;4%:8%:1 %;4%:8%:3%;12%:4%:0%;12%:4%:1%;12%:4%:3%;8%:8%:0%;8%: 8%:1%; 8%:8%:3%; 4%:12%:0%; 4%:12%:1%; 4%:12%:3%;

[0043] Its performance data can be found in the appendix image 3 .

[0044] By the experiment of embodiment 1-3, we can obtain following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com