Flow field optimization device capable of improving capacity of coal mill

An optimization device and coal mill technology, which is applied in the direction of grain processing, can solve the problems of reducing coal mill output, high energy consumption, and affecting the coal grinding effect, etc., to achieve improved output, simple structural design, and effective separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

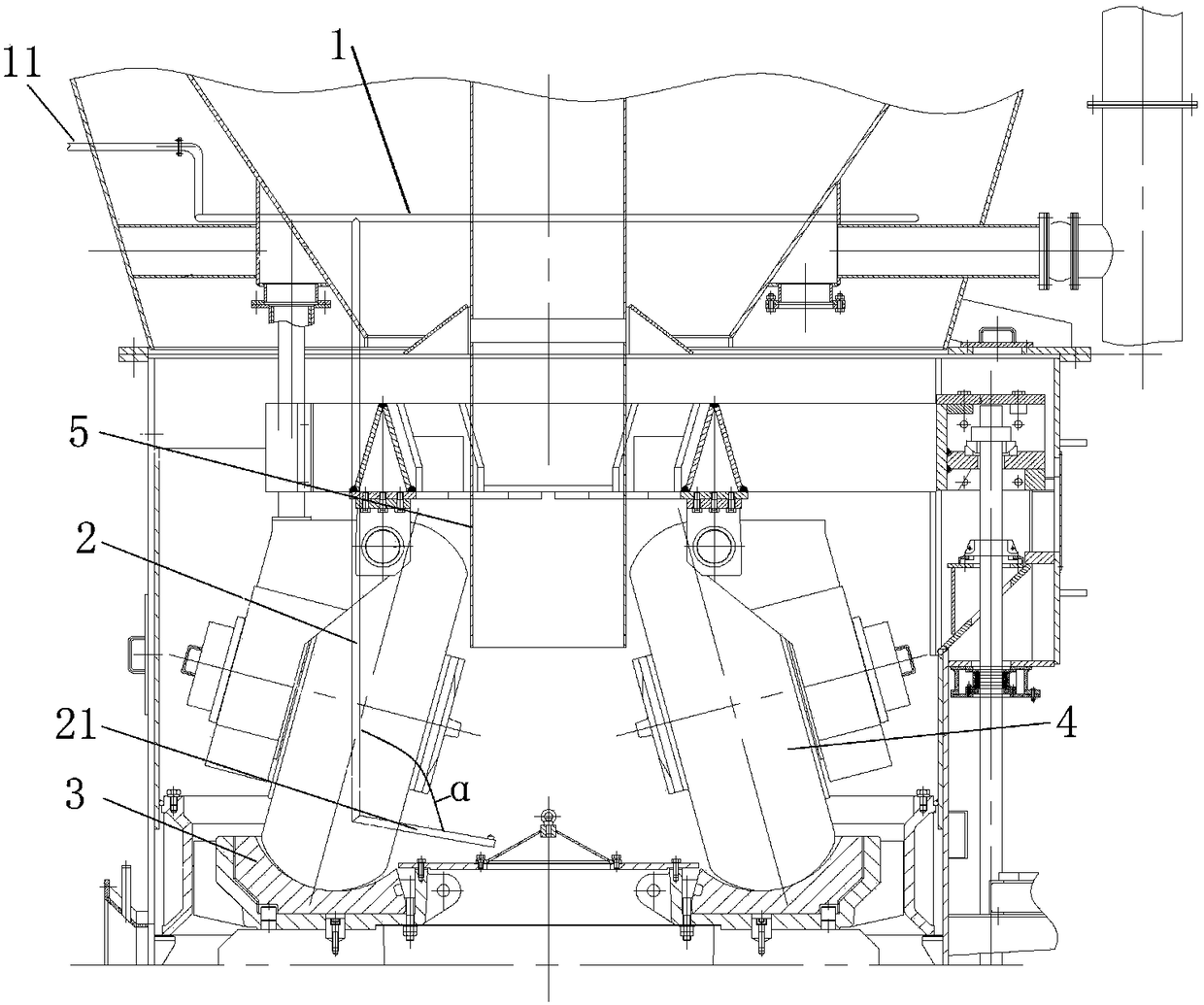

[0033] Example: such as Figures 1 to 4 As shown, the flow field optimization device for improving the output of the coal mill in this embodiment includes an air inlet pipe 1 and three air guide pipes 2;

[0034] The above-mentioned air inlet pipe 1 is arranged above the millstone 3 of the coal mill, and its air inlet extends out of the above-mentioned coal mill, and is externally connected to the air source;

[0035] Inside the coal mill, there are three grinding rollers 4 that are evenly spaced along the circumference of the above-mentioned grinding table 3 and are in rolling contact with the upper part of the grinding table 3, and the coal drop pipe 5 of the coal mill is located above the middle part of the above-mentioned grinding table 3;

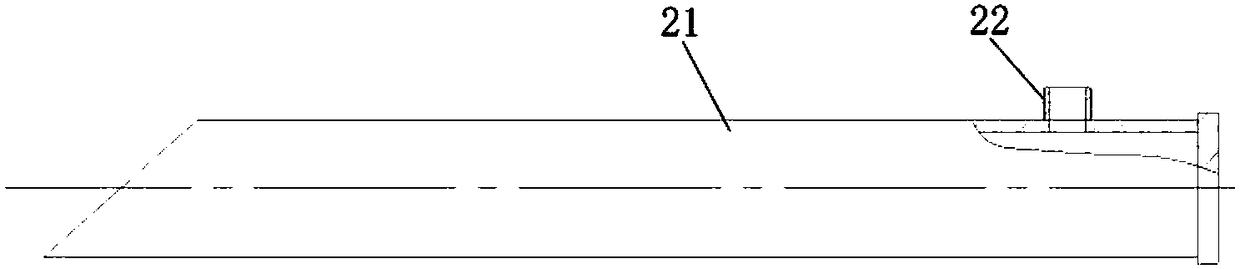

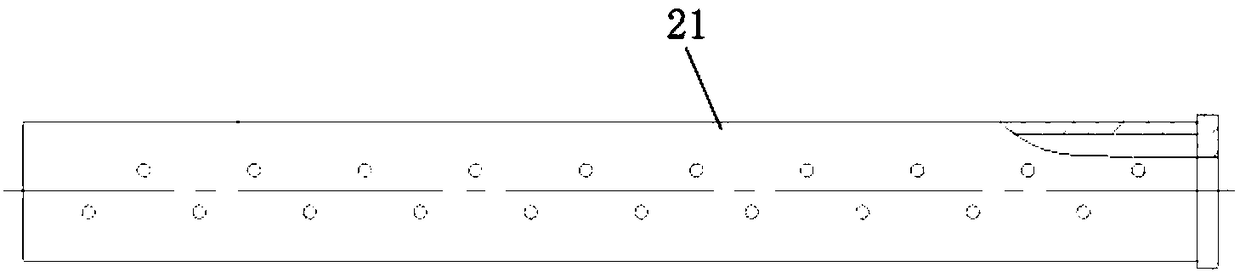

[0036] The three above-mentioned air guide pipes 2 are respectively arranged vertically above the edge of the above-mentioned grinding disc 3 along the circumferential direction uniformly and at intervals, and are respectively located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com