Building-material stirring equipment

A technology for mixing equipment and building materials, which is applied to cement mixing devices, unloading devices, clay preparation devices, etc. It can solve the problems of mixing bucket mixing dead angle, difficult to clean, time-consuming and labor-intensive, etc., to improve mixing speed, save labor costs, The effect of reducing time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

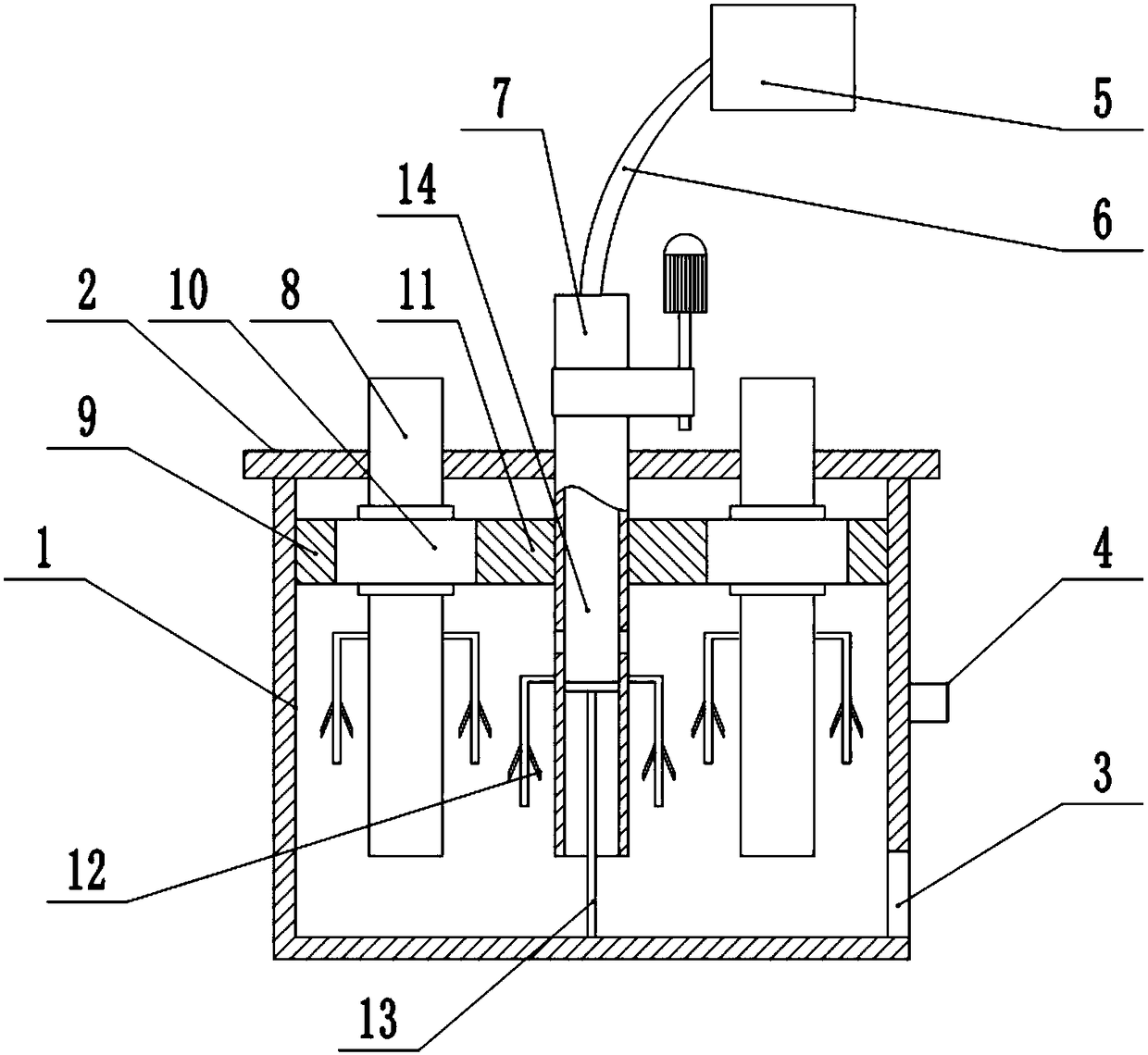

[0022] The reference signs in the drawings of the description include: mixing bucket 1, cover plate 2, discharge port 3, guide block 4, water bucket 5, water inlet pipe 6, stirring shaft 7, rotating shaft 8, inner ring gear 9, driven gear 10 , Drive gear 11, stirring blade 12, piston rod 13, water outlet trough 14.

[0023] Such as figure 1 As shown, the construction material mixing equipment includes a frame on which a mixing tank 1 is arranged, and the inner wall of the mixing tank 1 is provided with spike-like protrusions. A stirring shaft 7 is rotatably connected to the frame, and four rotating shafts 8 are rotatably connected to the surrounding of the stirring shaft 7 on the frame. The driving gear 10, the inner wall of the mixing tank 1 is spline connected with the inner ring gear 9 meshing with the driven gear 10, the frame is fixedly connected with a pole, the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com