Multilevel density compensation for digital printing machines

A color density, computer technology, applied in the field of correcting color density unevenness, can solve the problem of insufficient compensation in the image area, and achieve the effect of color density improvement and rapid correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

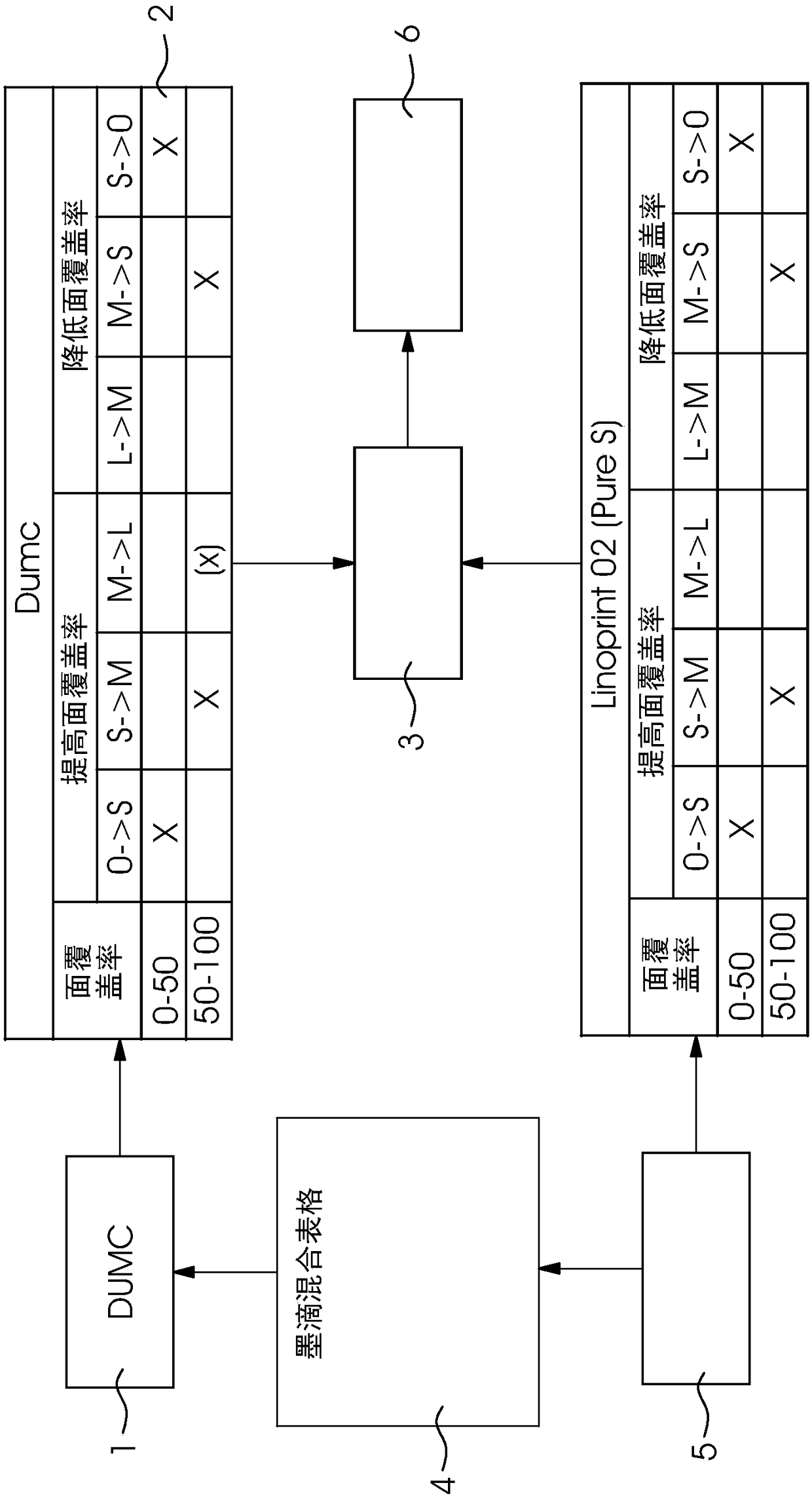

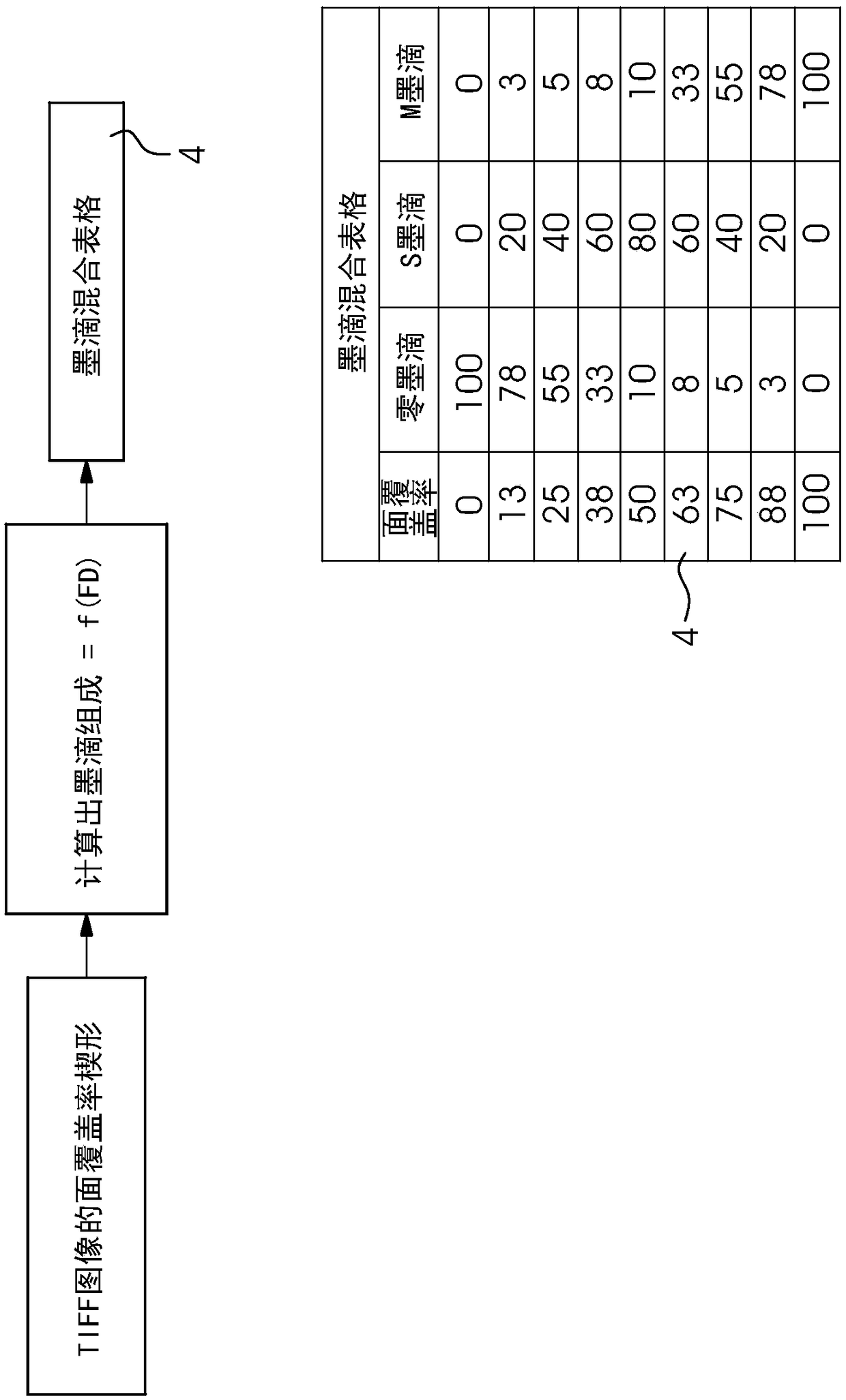

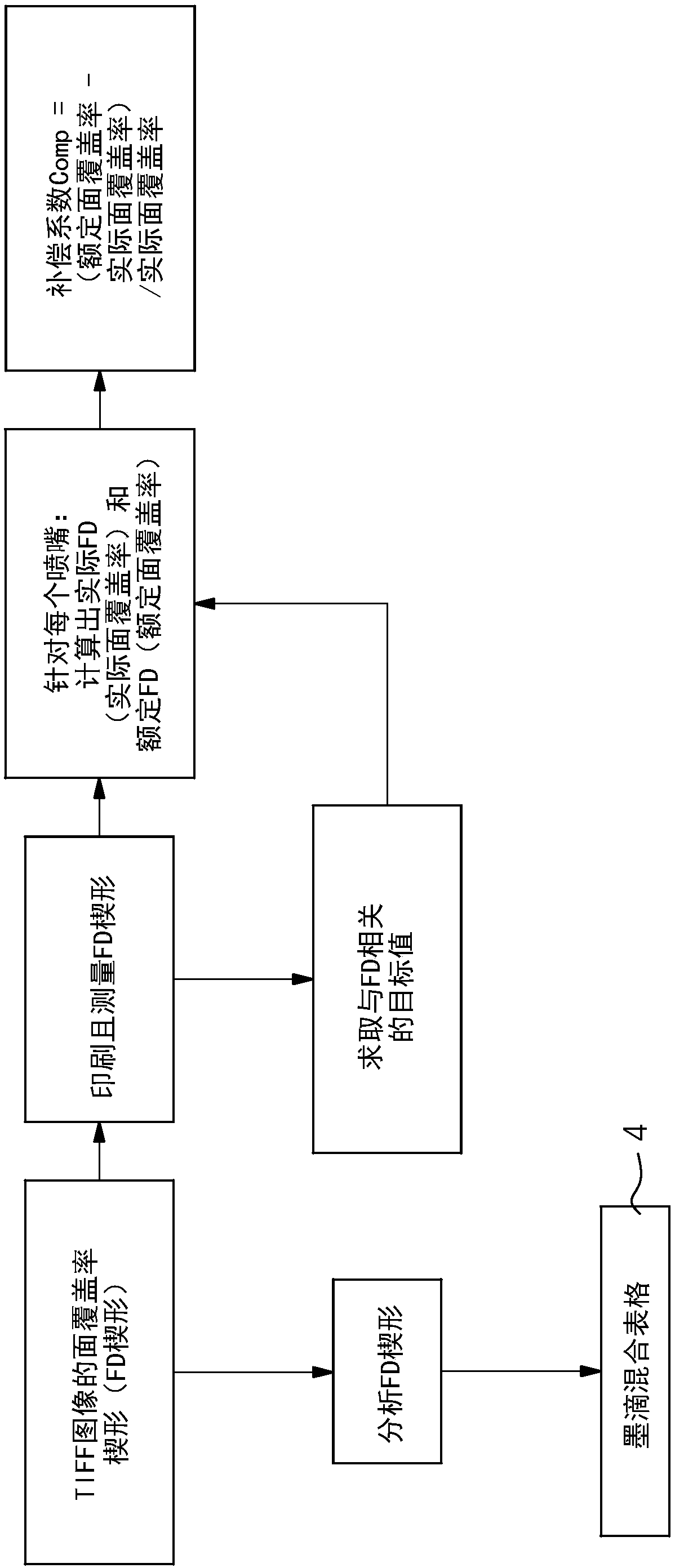

[0019] figure 1 The influence of the novel multi-level density compensation method (Multi-Level-Dichte-Kompensations-verfahren) on the screened printed image during the generation of ink droplets for the control of an inkjet printer is shown. First, as in the prior art, the printed image is screened into color separations by means of the screening method 5 . In the screening method 5, a color separation is produced in gray scale for each color. These grayscale pixels must then be converted into corresponding control parameters for controlling the printing nozzles of the inkjet printer. exist figure 1 , here working with two different drop sizes, namely: drop sizes S and M. In addition, from the conversion table Linoprint 02 (Pure S) of the screening software with screening type, it can be seen that when increasing the area coverage, in the range of area coverage between 0 and 50%, the image that does not exist will be The dots become small ink droplets S, and in the case o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com