A kind of low-carbon bainitic weathering steel and its production method

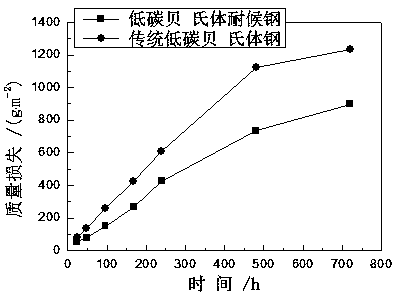

A low-carbon bainite and production method technology, applied in the field of low-alloy steel production, can solve problems such as accelerated corrosion of pearlite, and achieve the effects of good seawater corrosion resistance, good surface quality, good low-temperature toughness and weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

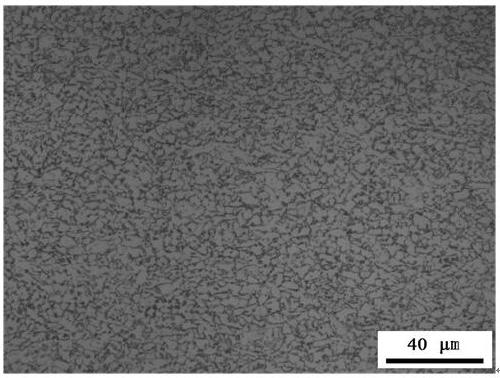

[0033] The weight percentage of chemical composition of steel is C=0.05, Si=0.62, Mn=1.25, P=0.012, S=0.0013, Al=0.033, Ti=0.014, Nb=0.012, Cu=0.66, Ni=0.80, Ca=0.0027 , the balance being Fe and unavoidable impurity elements.

[0034] The production process steps of steel include: use converter, LF furnace and RH furnace to smelt molten steel according to the above composition and continuously cast it into a slab, cool it to room temperature and then grind the surface, then reheat the slab for rolling and finishing, After the surface shot blasting, the heat treatment process of normalizing + accelerated cooling + isothermal aging is carried out, and finally the performance is tested by sampling.

[0035] The production process steps of steel include key process parameters: 250m of Ca wire is fed after the LF furnace, and the soft argon blowing time is 15min; 350m of the Ca wire is fed after the RH furnace, and the soft argon blowing time is 18min; ~14°C, steel flow rate 3.2t / ...

Embodiment 2

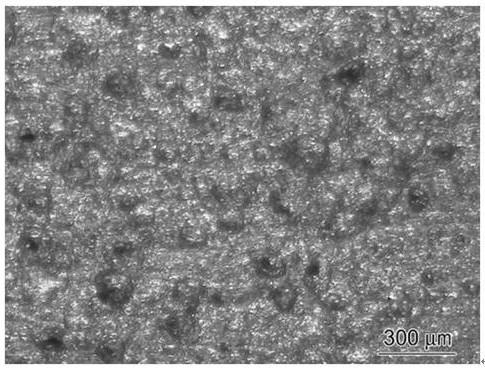

[0044] The weight percentage of chemical composition of steel is C=0.04, Si=0.65, Mn=1.23, P=0.013, S=0.0015, Al=0.030, Ti=0.016, Nb=0.015, Cu=0.64, Ni=0.82, Ca=0.0026 , Mo=0.11, Cr=0.17, the balance is Fe and unavoidable impurity elements.

[0045] The production process of steel includes the use of converter, LF furnace and RH furnace to smelt molten steel according to the above composition and continuously cast it into slabs. After the stack is cooled to room temperature, the surface is ground. After the surface shot blasting, the heat treatment process of normalizing + accelerated cooling + isothermal aging is carried out, and finally the performance is tested by sampling.

[0046] The key process parameters in this production method are: 250m of Ca wire is fed after the LF furnace, and the soft argon blowing time is 12min; 350m of the Ca wire is fed after the RH furnace, and the soft argon blowing time is 20min; 15°C, steel flow rate 3.2t / min, crystallizer vibration freq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com