Surface anti-fingerprint treatment technique for laptop housings

A notebook computer and processing technology, which is applied to special surfaces, pretreating surfaces, and devices for coating liquids on surfaces, etc., can solve the problems of easy adhesion of dust to protective glass, affecting product performance, and unsightly appearance of products, etc. To achieve the effect of unaffected performance, good anti-fouling and anti-fingerprint effect, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Such as Figure 1-4 The surface anti-fingerprint treatment process of the shown notebook computer casing comprises the following steps:

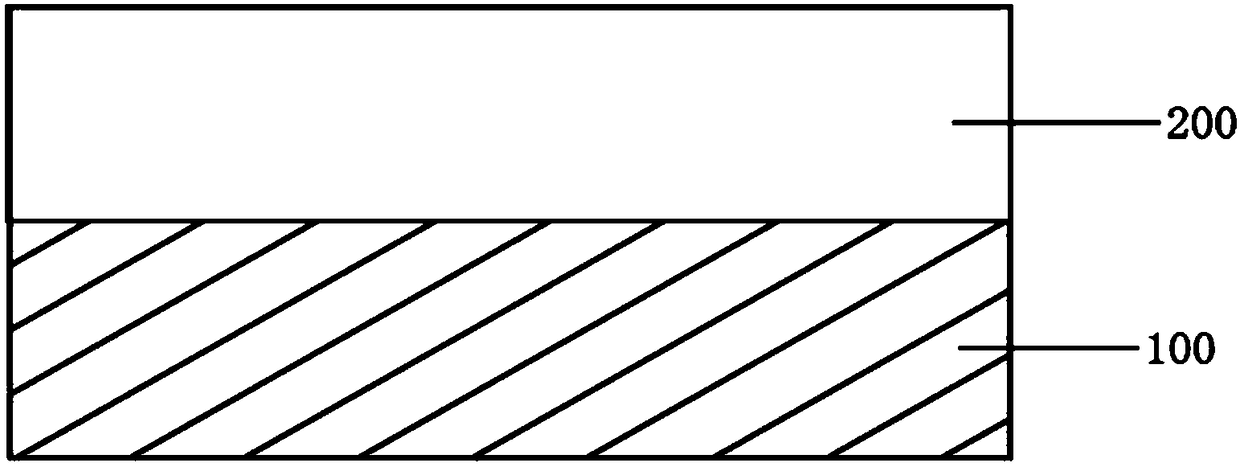

[0043] 1) Polishing the notebook computer case plate 100;

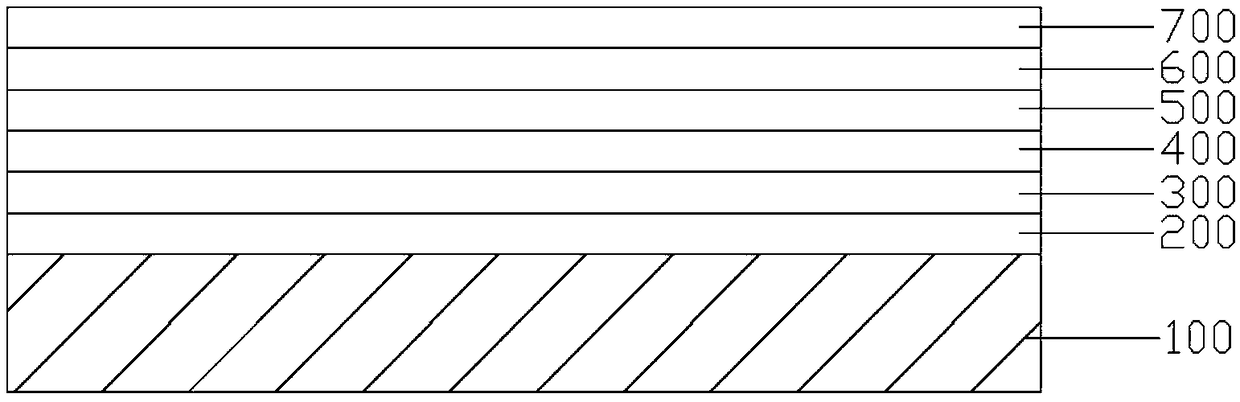

[0044] 2) Forming the first contact layer 200 on the surface of the notebook computer shell plate 100;

[0045]3) coating a layer of ink 300 on the first contact layer 200;

[0046] 4) After coating the ink 300, perform the first coating printing to form the first coating printing layer 400;

[0047] 5) Baking the notebook computer shell plate 100, and then dyeing after baking and curing to form a dyed layer 500;

[0048] 6) Carry out the second coating and printing on the dyed layer 500 to form the second coating and printing layer 600, and continue baking and curing;

[0049] 7) Before embossing, a second contact layer 700 needs to be attached above all layers;

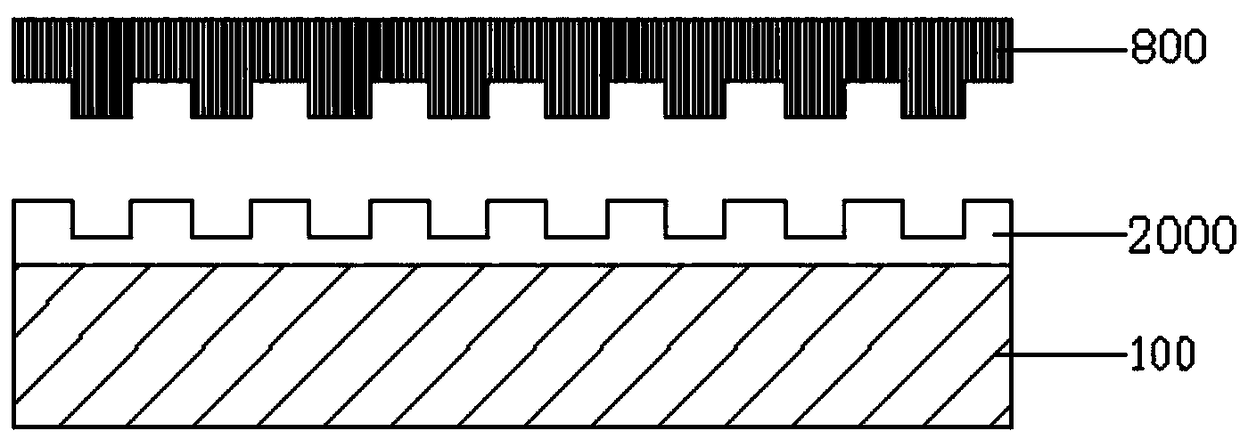

[0050] 8) Embossing with the mold 800, making textures, curing, and removing the mold 800;

[0051] 9) App...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com