Mechanical support device for semiconductor substrate processing microcavity

A substrate processing and mechanical support technology, applied in the field of chemical processing of semiconductor wafer surface, cleaning, etching and other similar processing devices, can solve the problems of increasing weight, increasing power, difficult level deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] "One embodiment" or "an embodiment" or "another embodiment" referred to in this specification means that specific features, structures or characteristics related to the embodiment can be included in at least one implementation of the present invention. The appearances of "in one embodiment" or "in another embodiment" in various places in this specification are not necessarily all referring to the same embodiment, nor are separate or selected embodiments mutually exclusive of other embodiments. "Multiple" in the present invention means two or more, and "several" means one or more. "And / or" in the present invention means "and" or "or".

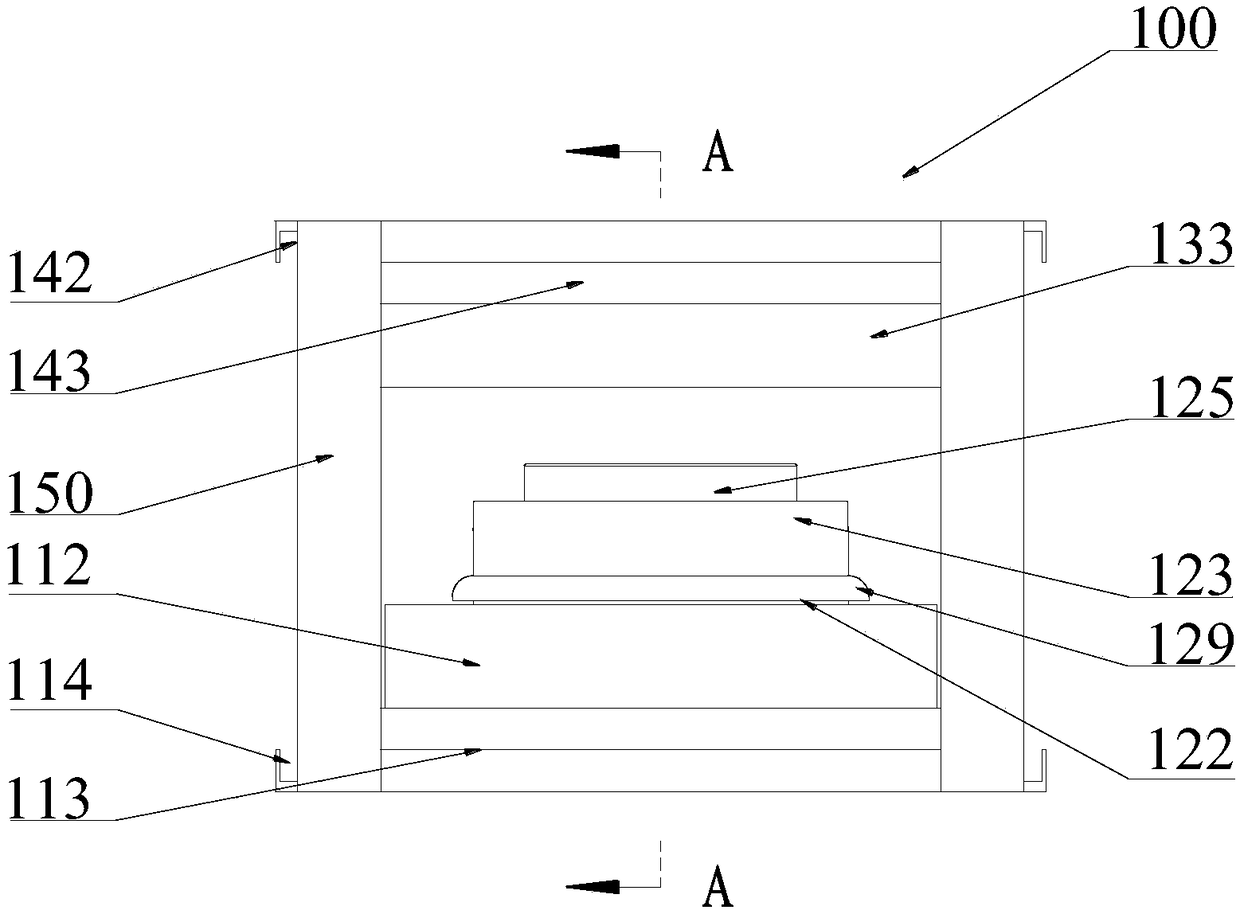

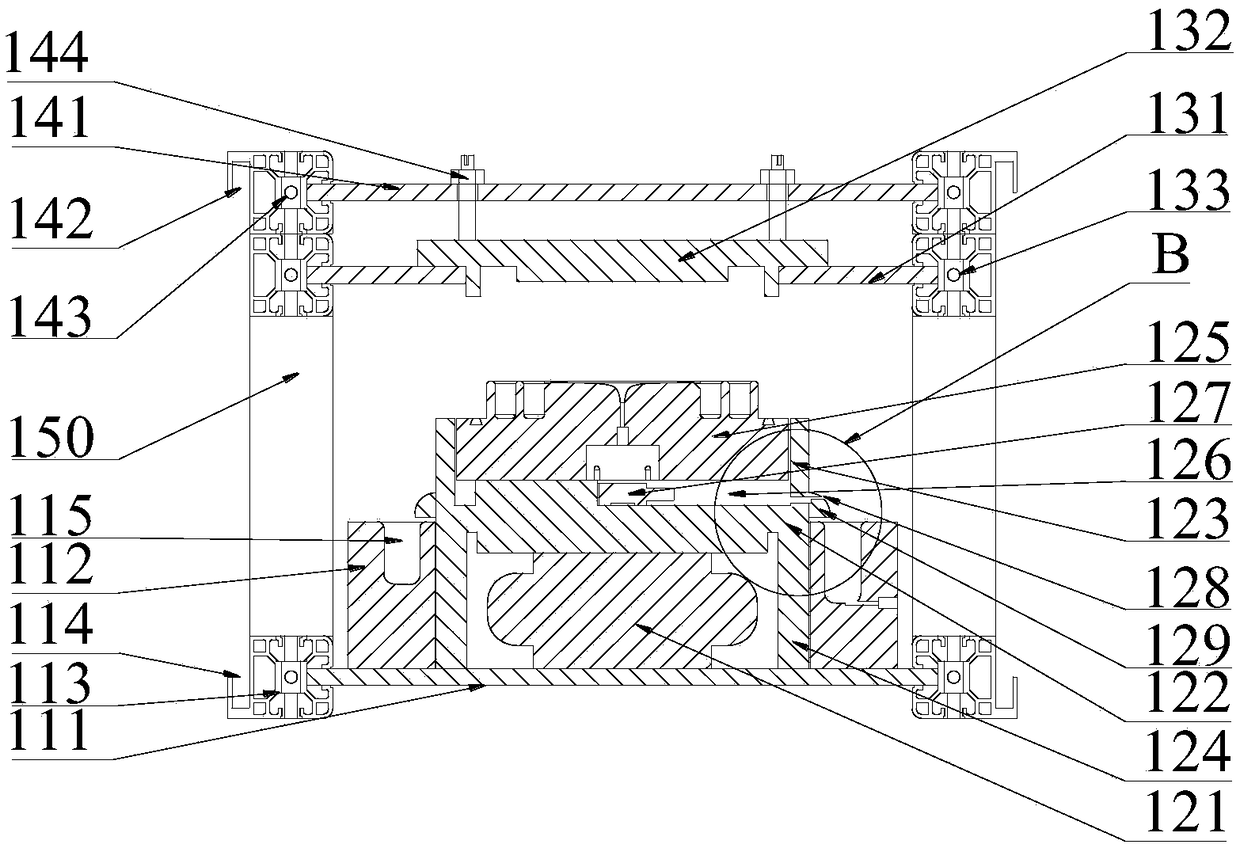

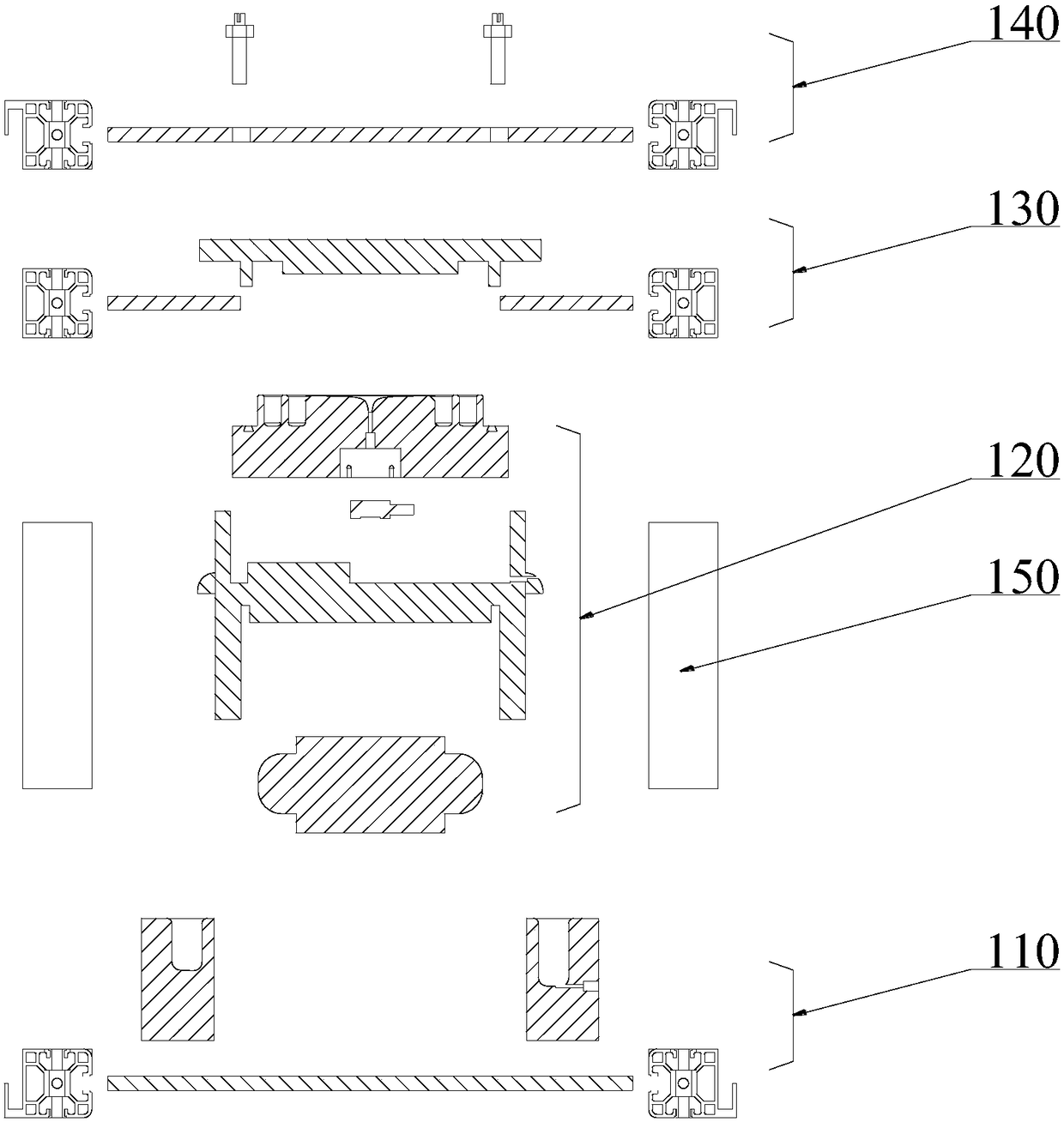

[0024] exist Figure 1 to Figure 5 The mechanical support device 100 of the semiconductor substrate processing microchamber of the present invention is schematically shown in .

[0025] Please refer to Figure 1-5 The mechanical support device 100 for the semiconductor substrate processing microchamber of the present invention may incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com