Permanent-magnetic rotor structure of motor of shielding pump

A permanent magnet rotor, shielded pump technology, applied in the shape/style/structure of the magnetic circuit, the rotating parts of the magnetic circuit, the magnetic circuit and other directions, can solve the problems affecting the performance of the motor, the limited improvement space, and the increase of the temperature of the motor, etc. Improve efficiency, improve motor performance, and reduce the effect of motor temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

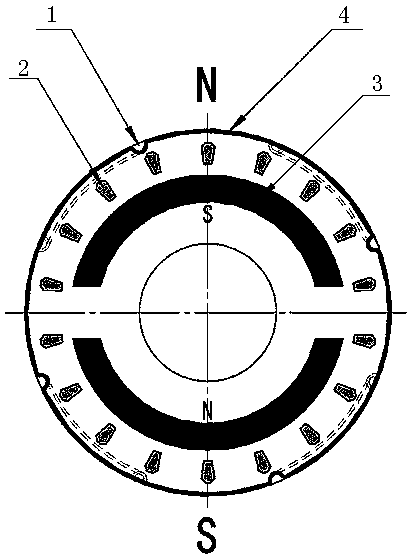

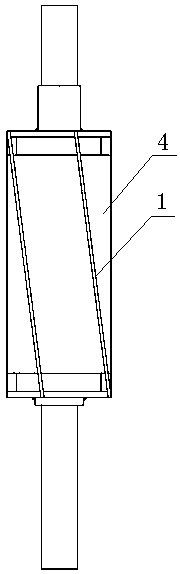

[0011] The structure of the permanent magnet rotor of the canned pump motor of the present invention is as follows: figure 1 and figure 2 As shown, it includes arc-shaped magnetic steel 3, cast aluminum winding 2 and shielding sleeve 4, the rotor is embedded with arc-shaped magnetic steel 3, the rotor is provided with cast aluminum winding 2, the outer side of the rotor is provided with shielding sleeve 4, and the stainless steel shielding sleeve 4 is on the A diversion groove 1 is provided.

[0012] The invention adopts the matching structure of the permanent magnet synchronous motor and the pump, designs a self-starting permanent magnet synchronous shielded electric pump, designs a self-starting cast aluminum winding 2 on the rotor, and relies on the asynchronous torque generated by the interaction between the stator rotating magnetic field and the cage rotor to realize starting . During normal operation, the rotor runs at synchronous speed, and the cage rotor no longer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com