Flower planting equipment

A flower and equipment technology, applied in the field of flower planting equipment, can solve the problems of fertilizer residue, uneven concentration of received fertilizer, easy sedimentation of fertilizer at the bottom of a kettle, etc., and achieve the effect of preventing waste and uniform concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

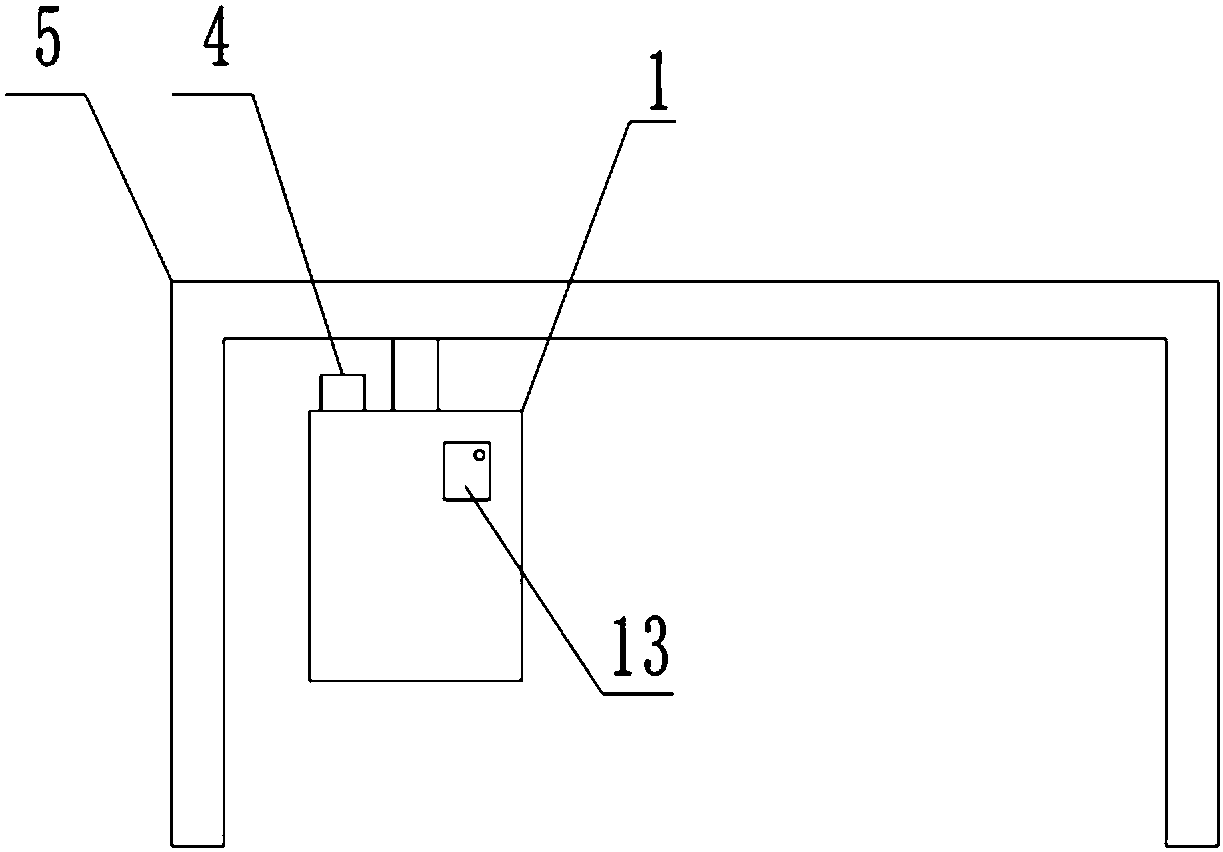

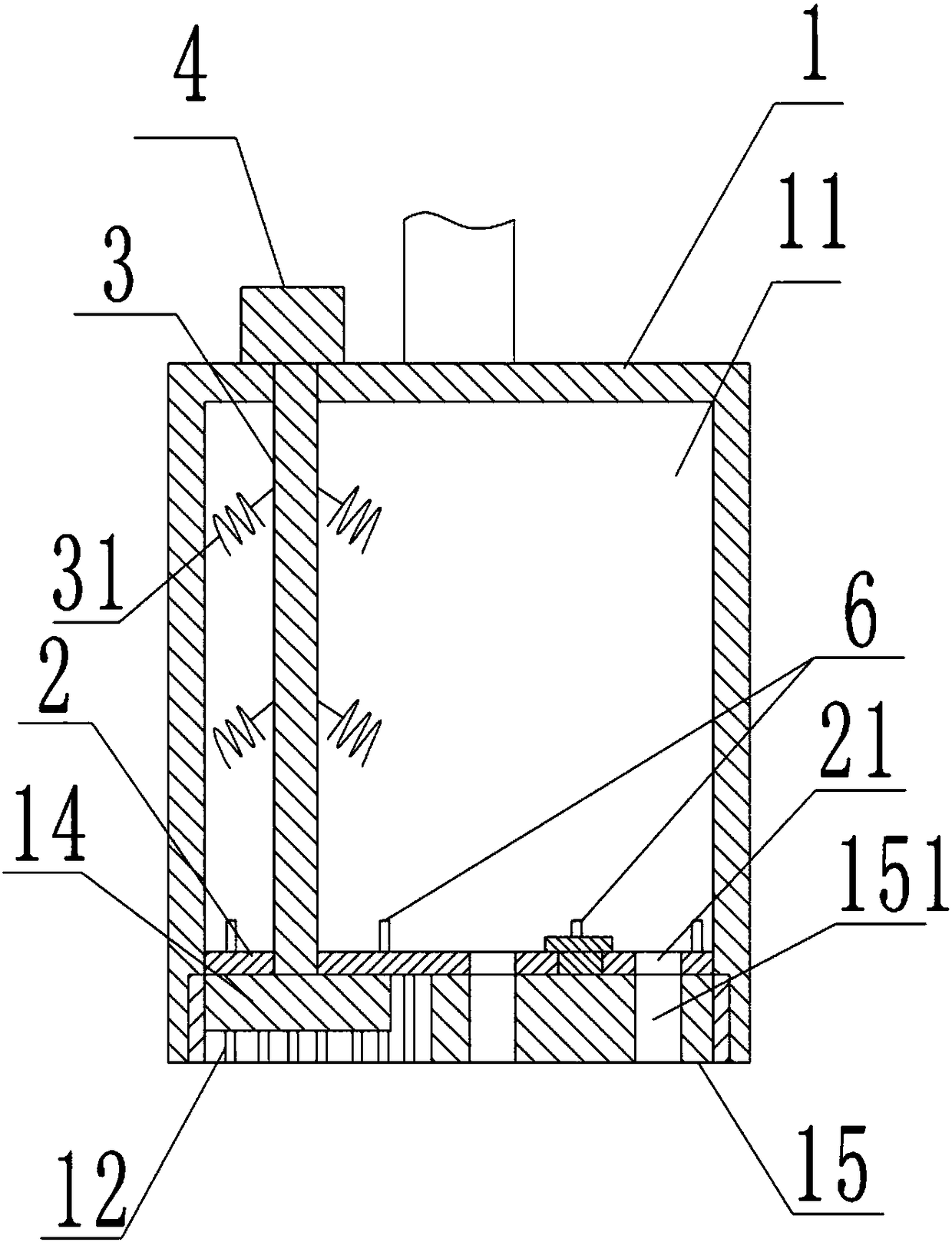

[0020] The reference numerals in the accompanying drawings of the description include: material tank 1, material chamber 11, inner ring gear 12, material inlet 13, power gear 14, material discharge gear 15, through hole 151, partition plate 2, material discharge hole 21 , stirring shaft 3, stirring pole 31, motor 4, support frame 5, rubber column 6.

[0021] Such as figure 1 and figure 2 As shown, in order to achieve the above object, the basic scheme of the present invention is as follows: the equipment for planting flowers includes a mixing tank 1, a dividing plate 2 and a stirring shaft 3 driven by a power unit; On the inner wall, and the partition plate 2 divides the material tank 1 into a material cavity 11 and a rotating cavity; the material tank 1 is also provided with a feed port 13 for discharging materials into the material cavity 11; the inner wall of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com