Fluid-chip separation device for metal cutting machines

A metal cutting and separation device technology, applied in metal processing machinery parts, filtration separation, separation methods, etc., can solve the problems of insufficient separation effect, inability to recover cutting fluid and debris, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

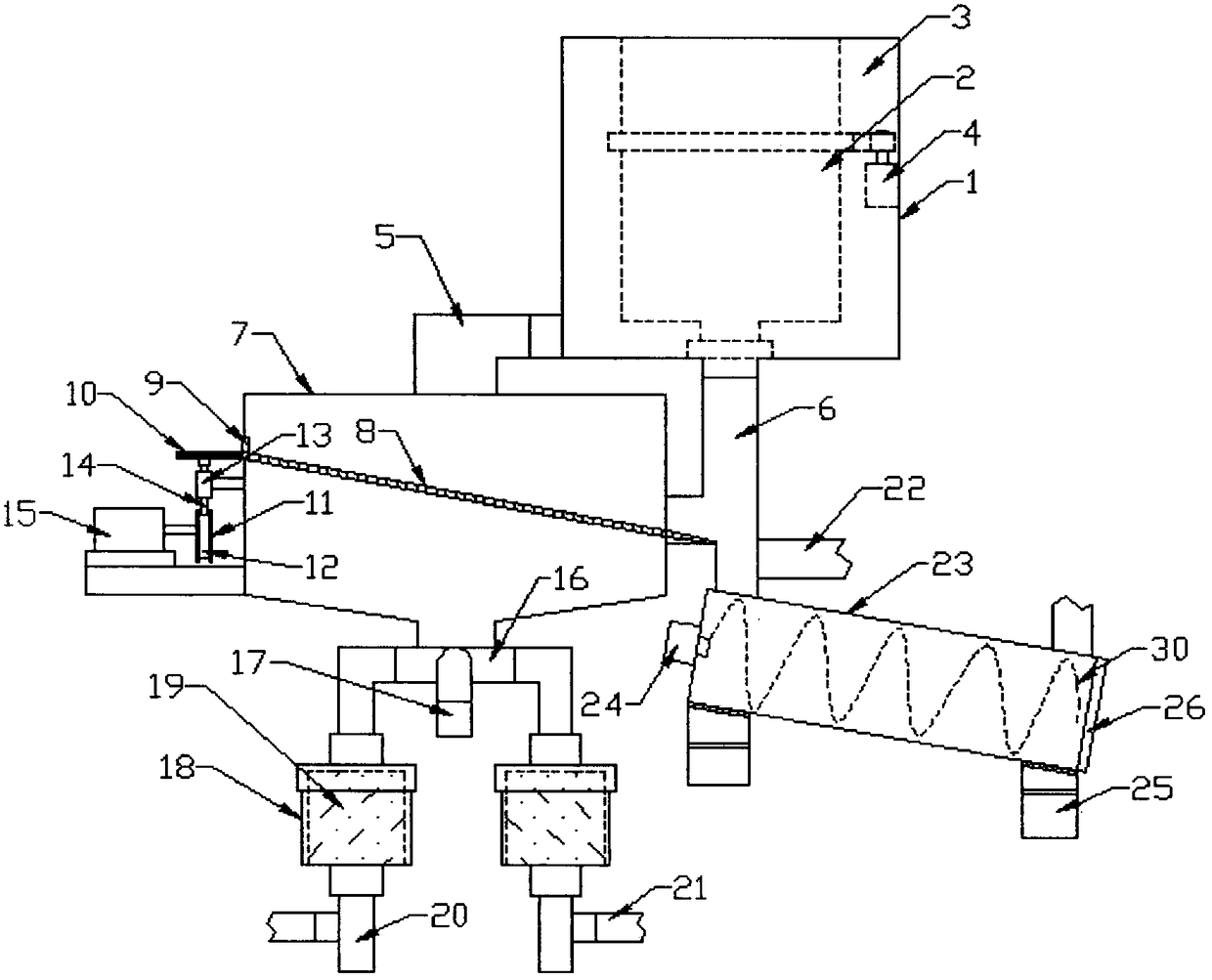

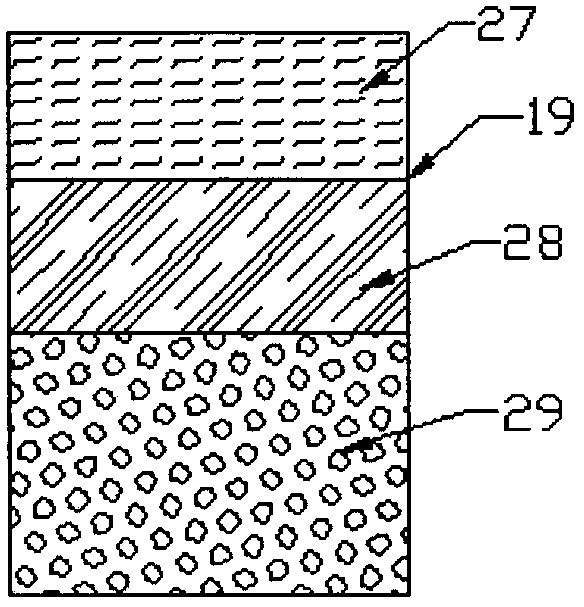

[0019] Example: such as Figure 1-2 As shown, the present invention is a liquid chip separation device for metal cutting machine tools, including a separator 1, the separator 1 includes a separation barrel 2, the separation barrel 2 is made of a filter screen 27, and the outer side of the separation barrel 2 is provided with a storage A No. 1 motor 4 is installed on the inner wall of the liquid chamber 3 and the liquid storage chamber 3. A No. 1 gear is fixed outside the output shaft of the No. 1 motor 4. A rack is fixed outside the separation barrel 2. The No. 1 gear is connected to the rack by a chain, and the storage One side of the bottom of the liquid chamber 3 is provided with a liquid outlet, and the liquid outlet is connected with a catheter 5, and the outlet of the catheter 5 is connected to the inlet of the separation box 7, and the outlet of the bottom of the separation barrel 2 Connect the chip guide tube 6, and the chip guide tube 6 is also connected to the separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com