High-precision air flow control type stable film forming method using glue spinning machine

A technology of airflow control and film forming method, which is applied in the direction of pretreatment surface, coating, surface coating liquid device, etc. Small air flow disturbance, optimized film formation effect, and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

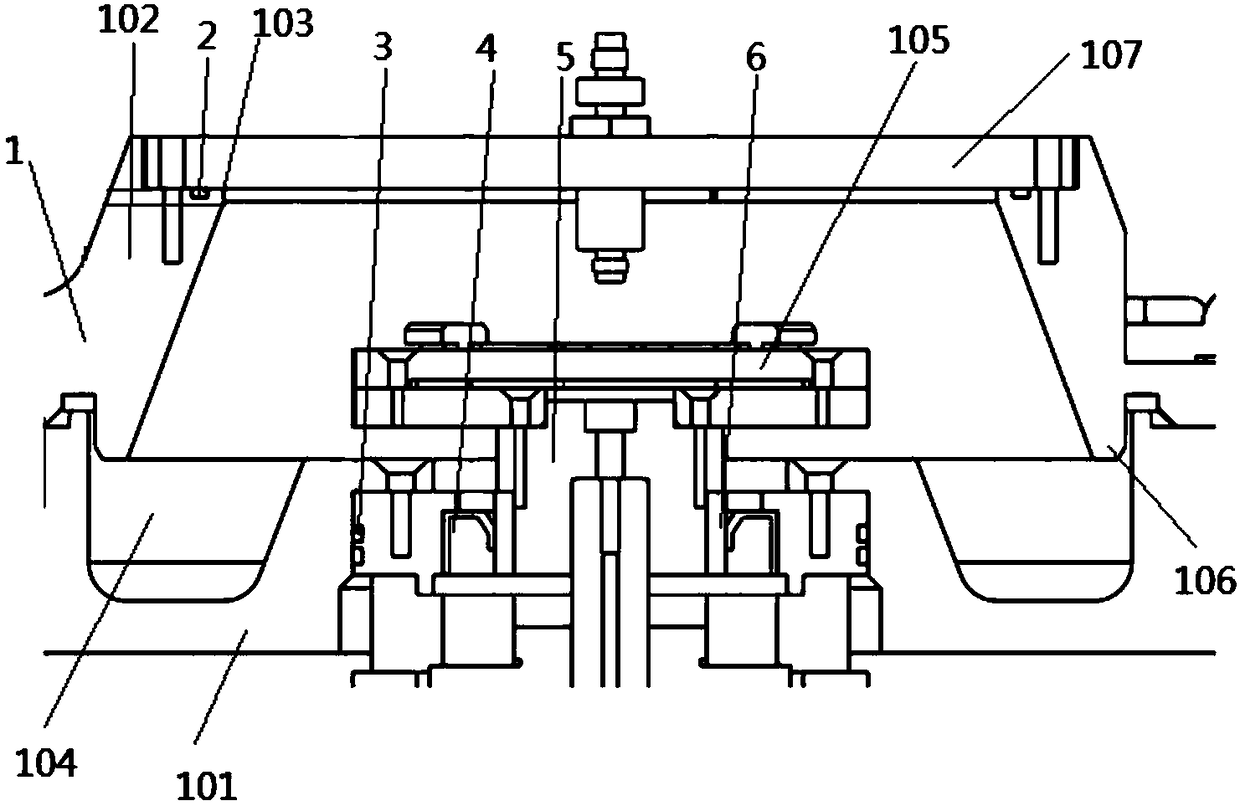

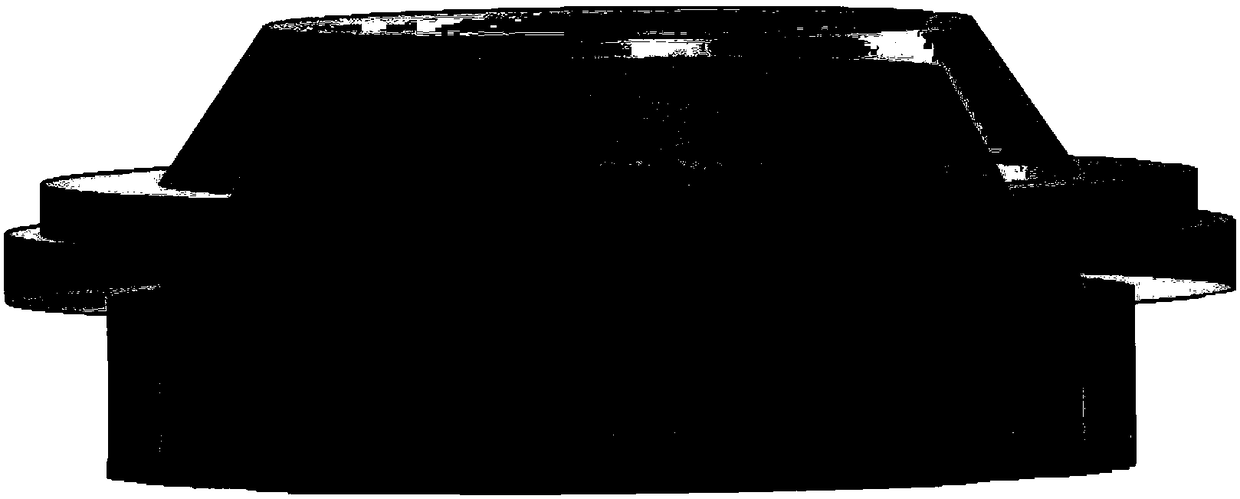

[0018] see Figure 1~3 , the present invention relates to a high-precision glue homogenizer airflow control stable film-forming method, the film-forming method is based on a glue homogenizer, the structure includes an upper cover 102 placed on the tray 101, the upper An observation window 107 is provided on the cover 102, a heating and rotating cavity is formed between the tray 101 and the upper cover 102, and the heating and rotating object tray 105 is located in the heating and rotating cavity;

[0019] The bottom of the tray 101 is provided with a ring-shaped spin-coating inner chamber 104, and the bottom of the upper cover 102 is provided with a ring-shaped guide step 106, and the guide step 106 is inserted in the spin-coating inner chamber 104, the The inner wall of the loam cake 102 is a tapered structure, and the top cover wall of the loam cake 102 is provided with an exhaust hole 103; The upper cover 102 is provided with a ring-shaped groove on its contact surface wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com