Method for predicting crystallizer breakout based on agglomerative hierarchical clustering

A technology of agglomerative hierarchical clustering and hierarchical clustering, which is applied in the field of iron and steel metallurgy continuous casting detection, can solve the problems of increased number of false alarms, low sensitivity, and decreased forecast accuracy, and achieves the alarm accuracy rate without missing alarms and robustness. And the effect of good stability and fast alarm response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

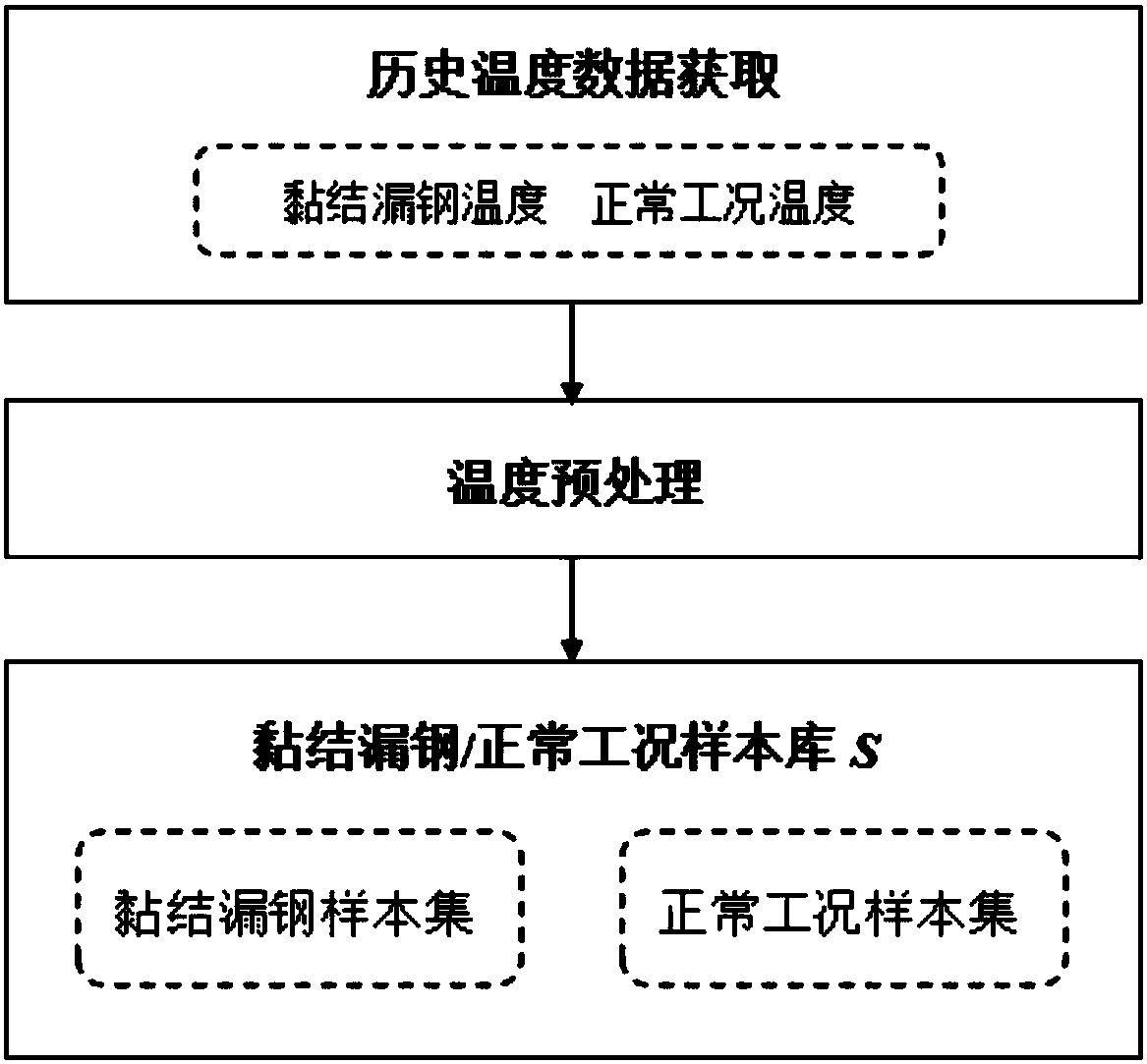

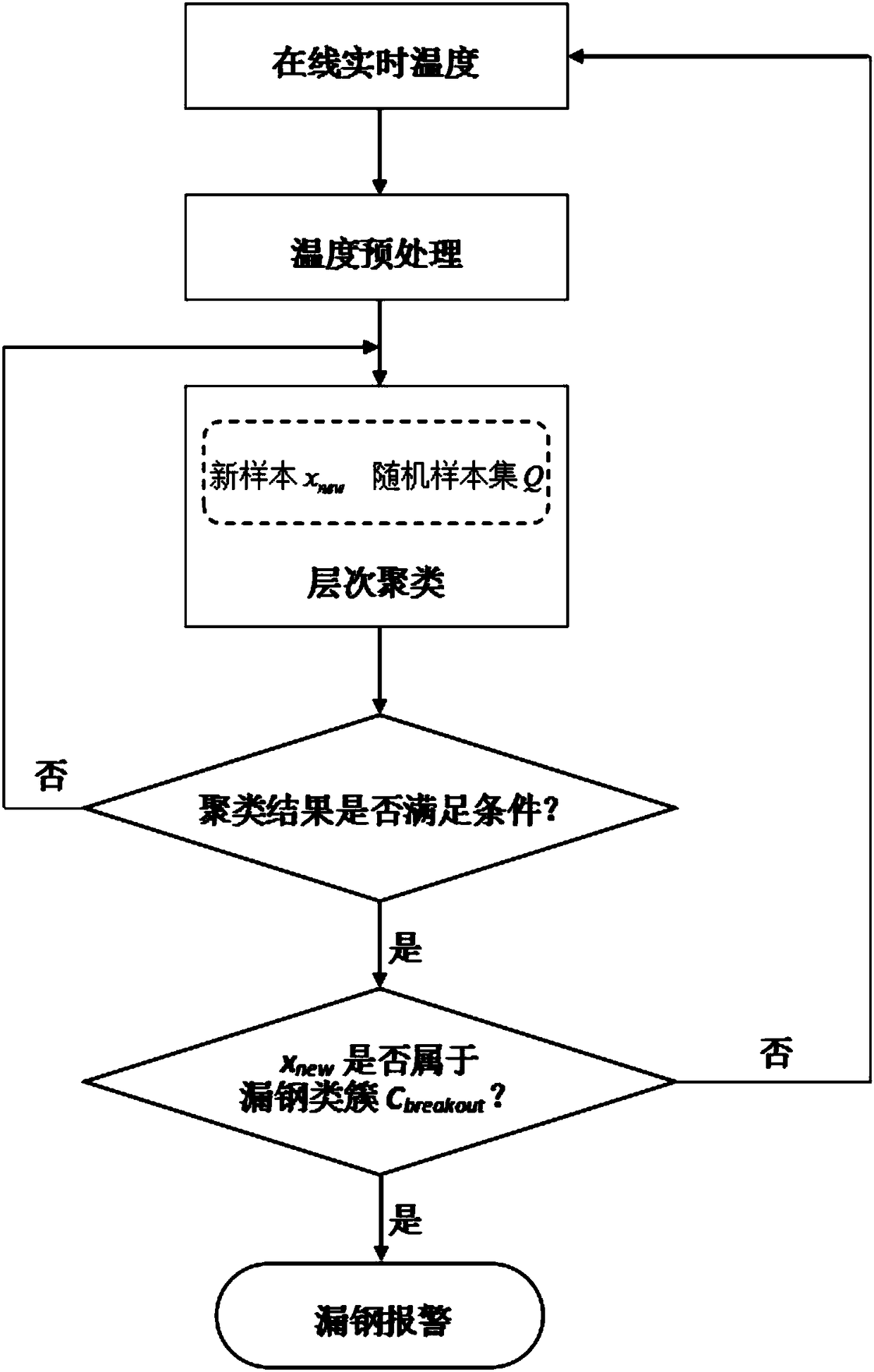

[0052] The invention mainly consists of three parts: establishment of bonded breakout / normal working condition sample library, random sample set hierarchical clustering, breakout identification and alarm.

[0053] Step 1. Establish bonded breakout / normal working condition sample library

[0054] figure 1 Create a flow chart for bonded breakout / normal working condition sample library. Depend on figure 1 It can be seen that the establishment of the sample library mainly includes the following sub-steps:

[0055] (1) Extract historical temperature data, which includes two parts: breakout temperature data where real bonding occurs and temperature fluctuation data under normal working conditions.

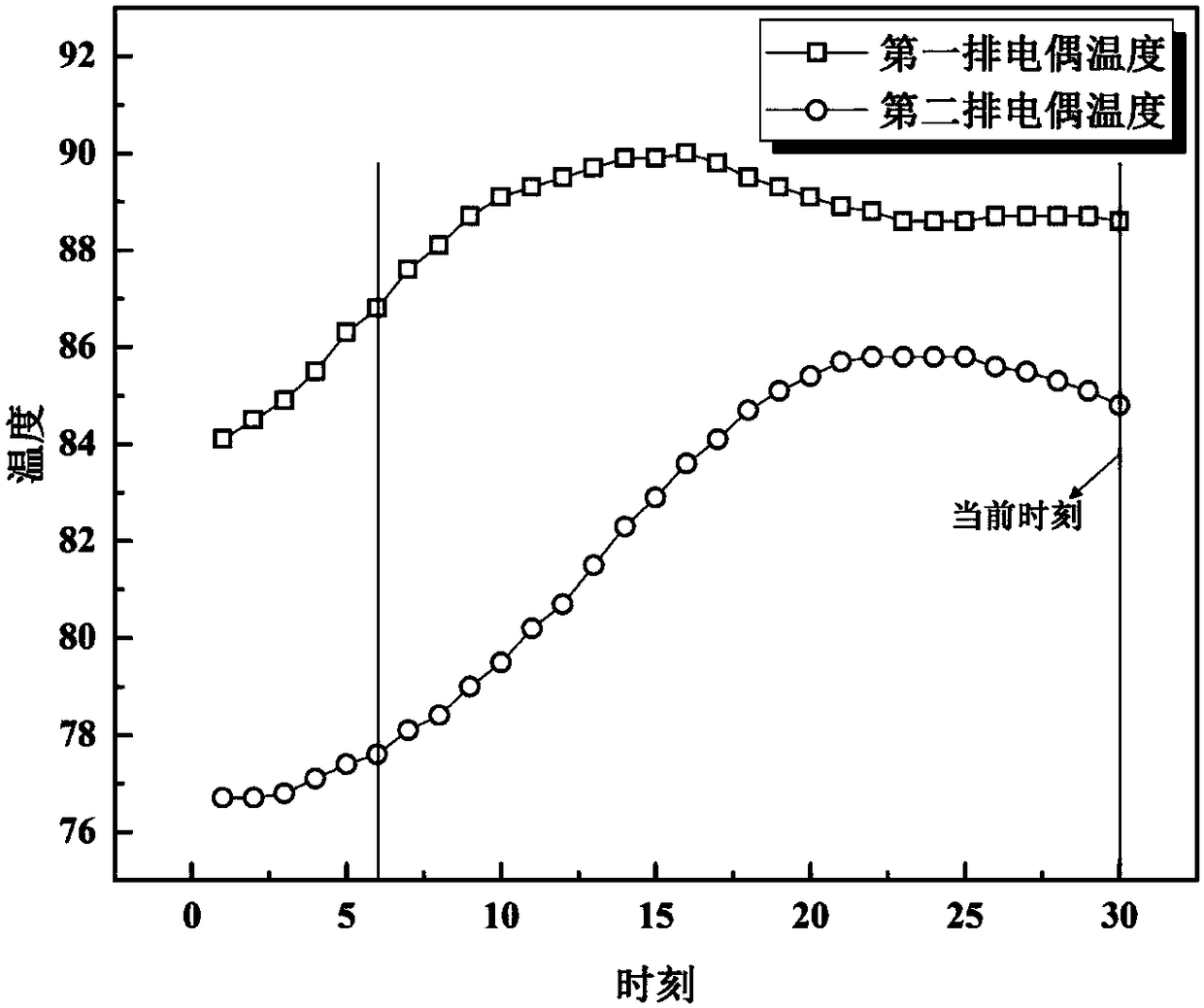

[0056] 1.1) For the actual bonded breakout temperature, mark the moment of the highest temperature of the first row of galvanic couples where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com