Milling cutting method of large melon petal shaped aluminum alloy component

An aluminum alloy and component technology, which is applied in the field of allowance milling of large thin-walled components, can solve problems such as troublesome operation, and achieve the effects of precise product, saving manufacturing cost and time cost, and high one-time pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

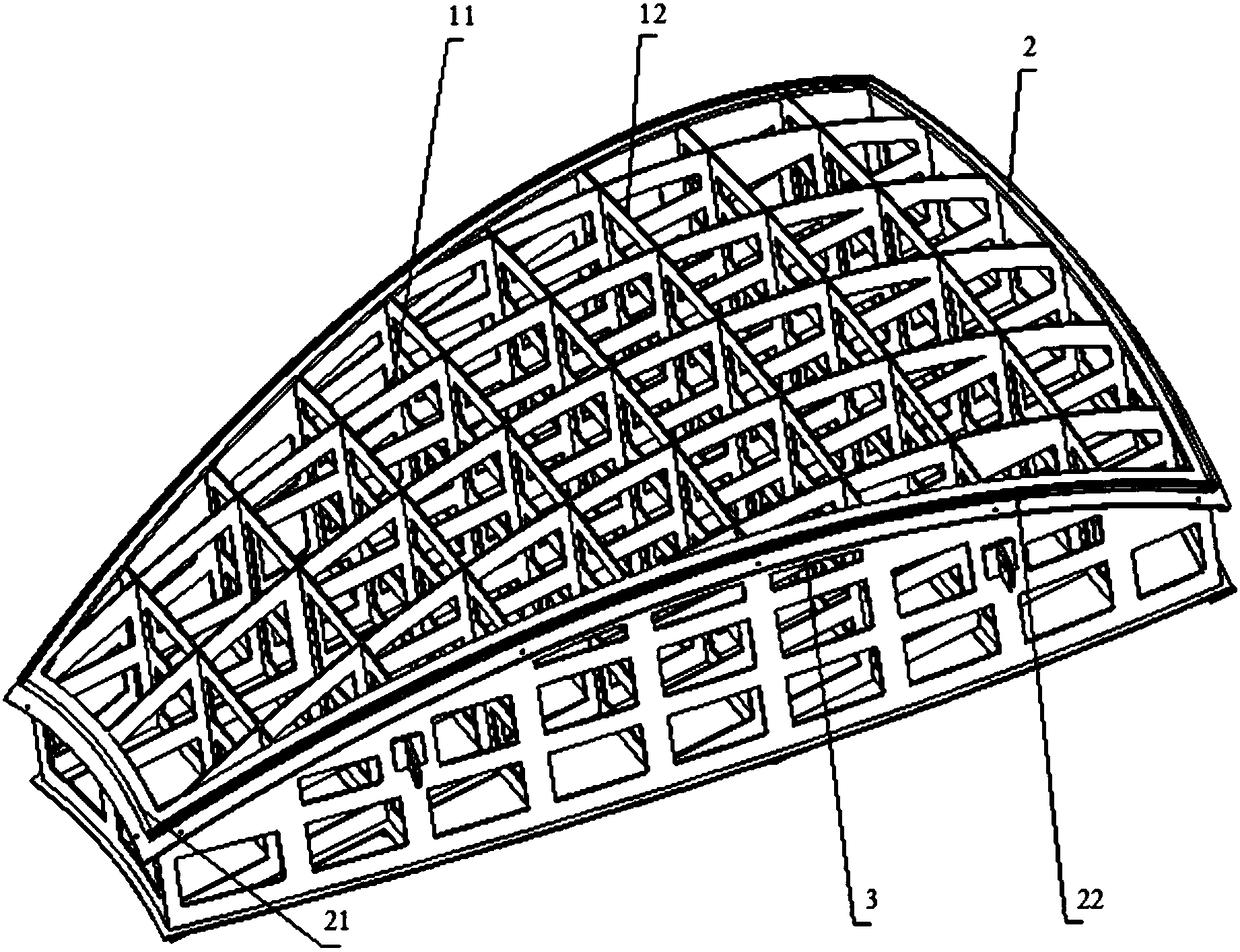

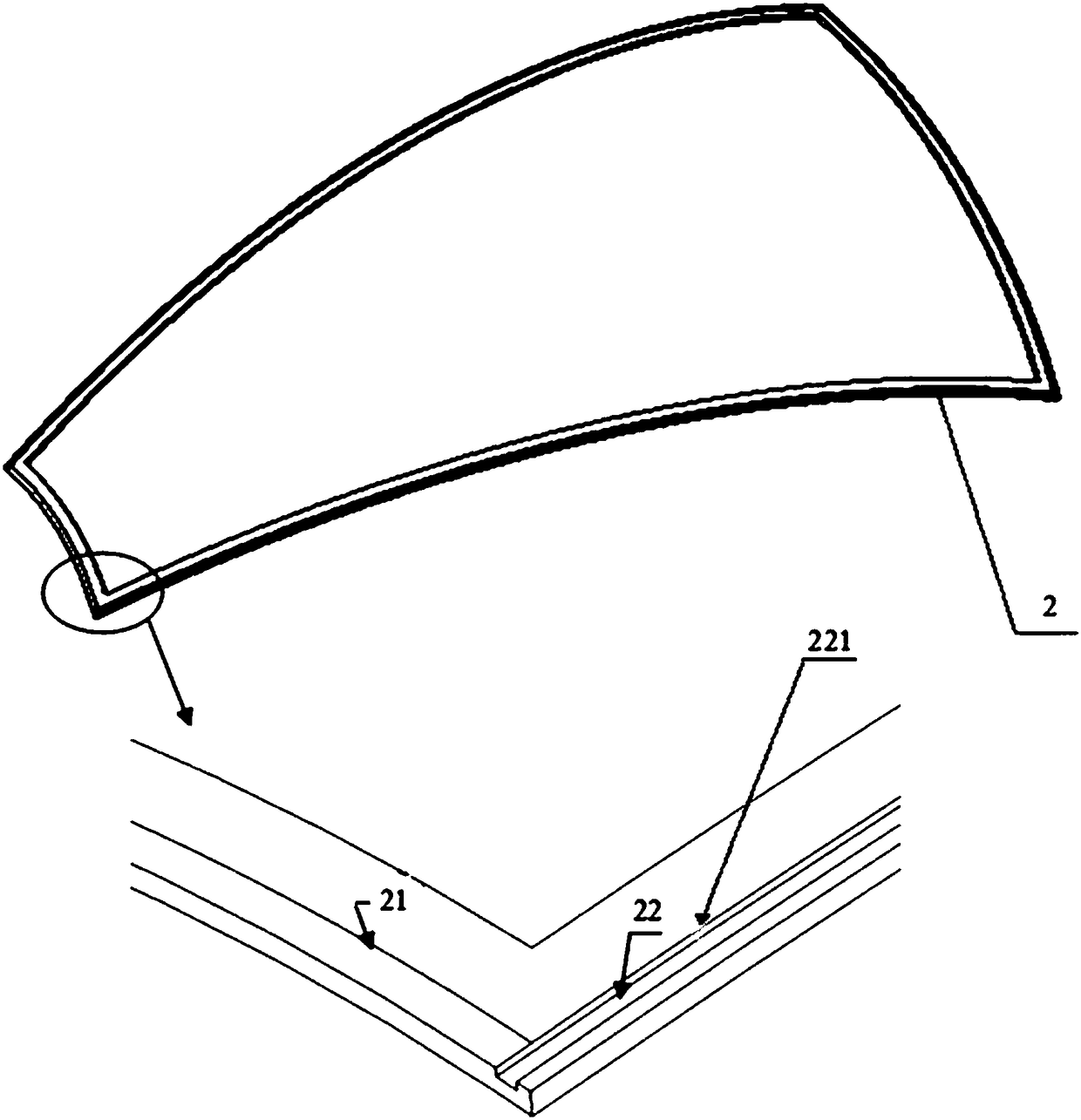

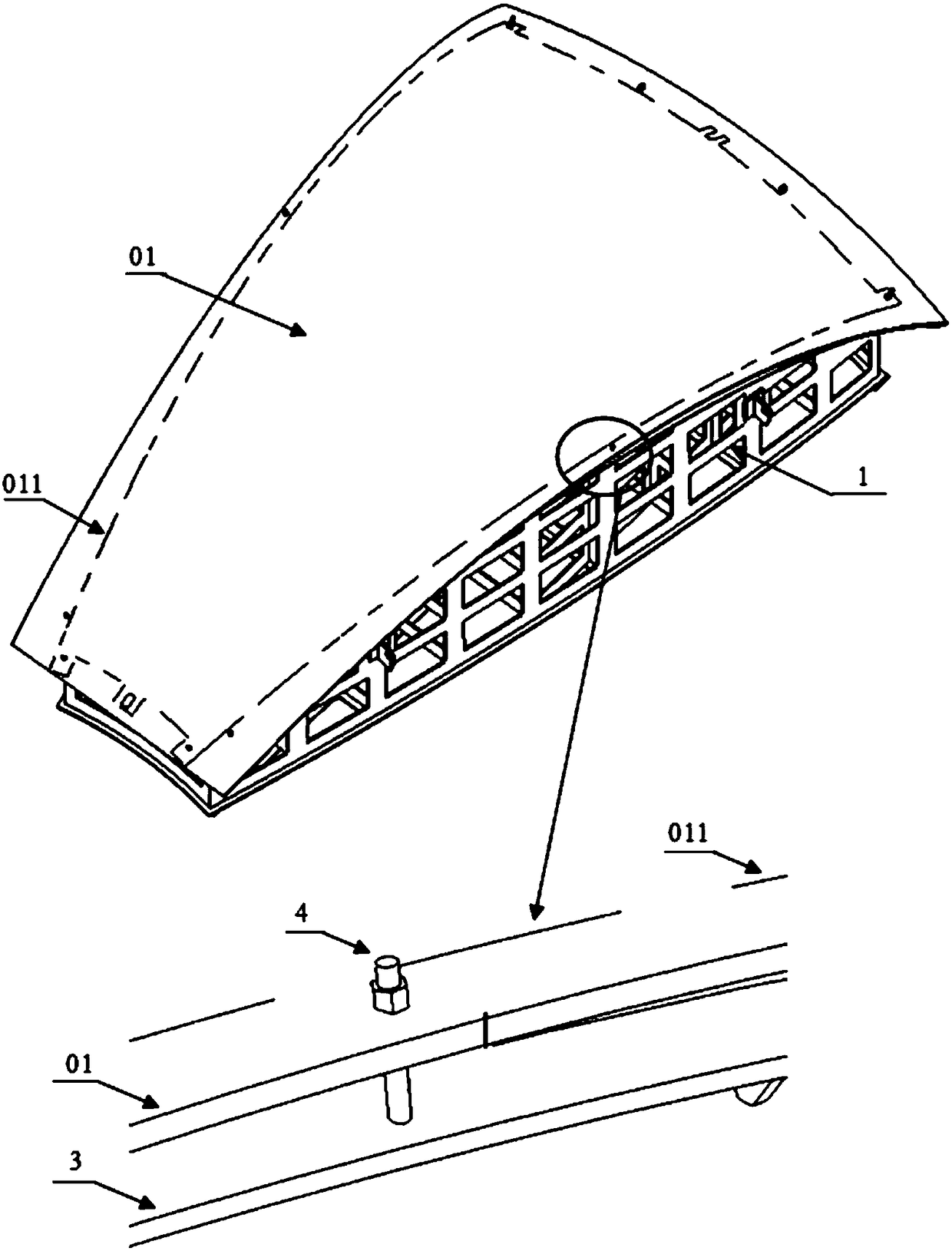

[0032] The present invention firstly provides a kind of large-scale thin-walled component surface accuracy detection and margin milling composite tooling (composite device), such as figure 1 As shown, its basic features include that the tooling has the function of detecting the surface accuracy of thin-walled components and the function of milling the surrounding allowance; The tooling described before the accuracy test is mainly composed of a clamping plate 1, a narrow panel 2 around, a knife groove 22 arranged on the panel 2 around the narrow panel 2, a theoretical line 21, and a pressure bearing plate 3, such as figure 1 . The horizontal and vertical clamps are made of 10mm thick steel plates. In order to achieve weight reduction and ensure sufficient strength and rigidity, holes are opened in the middle of the clamps. Weld a 75mm×18mm (width×thickness) narrow profile around the top surface of the integral frame tooling, such as figure 2 , where the theoretical profile i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com