System and method of segment water curing and carrying

A handling system and segment technology, which is applied in transportation and packaging, auxiliary forming equipment, ceramic molding machines, etc., can solve the problem of high manpower requirements, poor automation and poor movement continuity, and the inability to realize the water-supported vertical side of segments. Placement status and other issues to achieve the effect of saving volume, good promotion value, and reducing manual participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

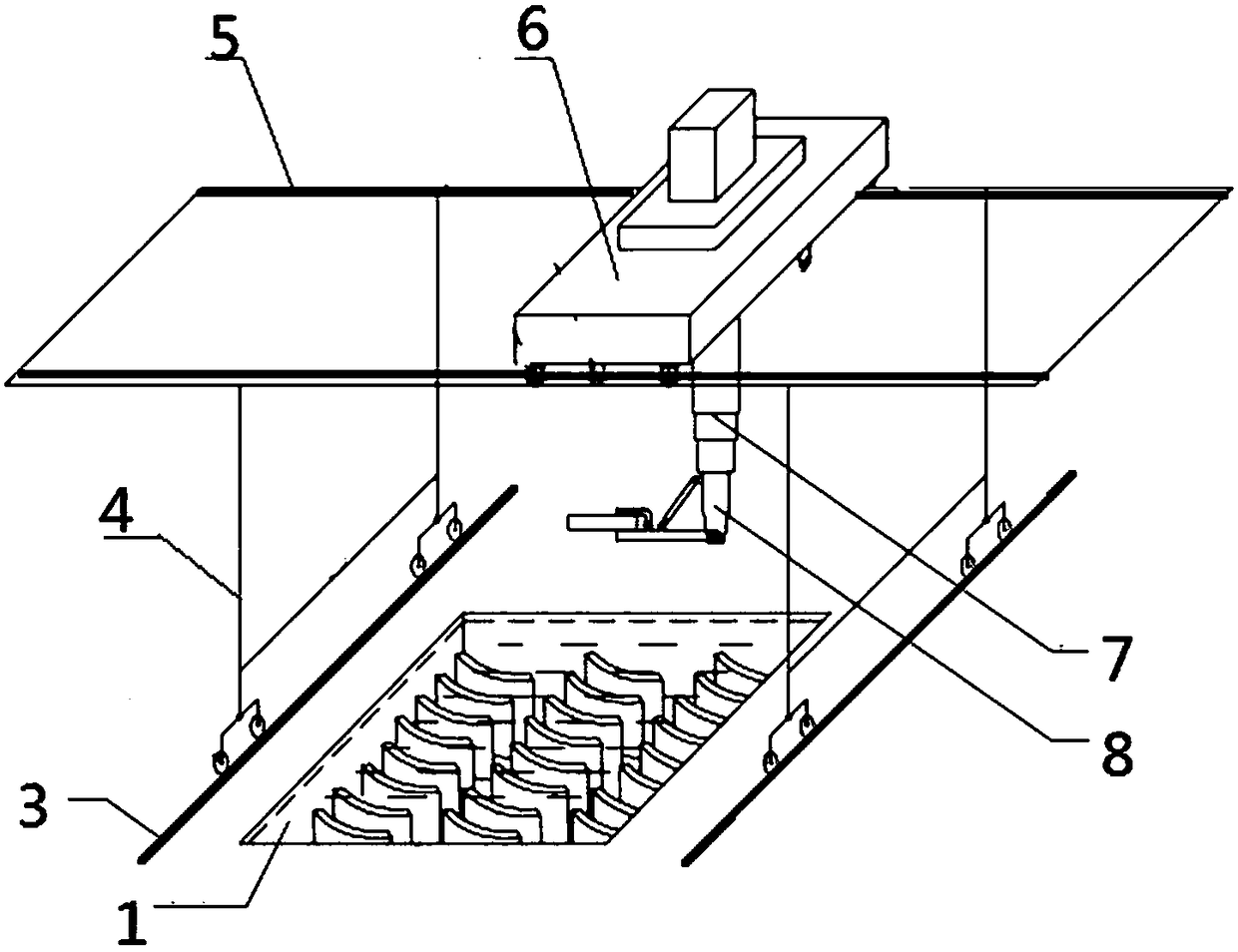

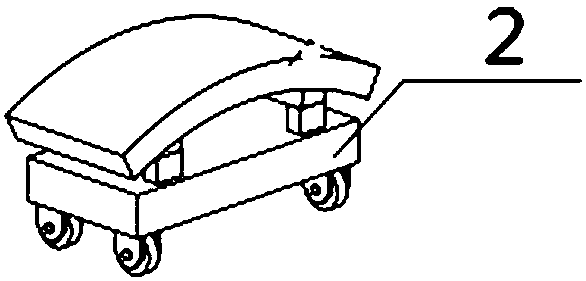

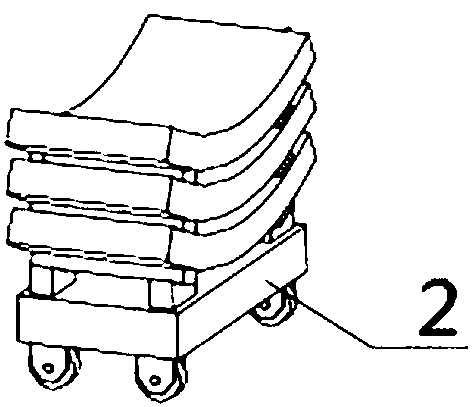

[0034] As a most basic embodiment of the present invention, such as figure 1 , this embodiment discloses a hydroponics transportation system for segments, including a hydroponics pool 1, a pick-and-place turning mechanism arranged on the hydroponics pool 1, and a running trolley 2 for transporting segments; the hydroponics pool The side of 1 is provided with a cart track 3 for the operation of the pick-and-place turning mechanism; the pick-and-place turning mechanism includes a gantry 4 erected on the cart track 3 on the side of the water tank 1, and the gantry 4 includes a driving mechanism for Drive the gantry 4 to run on the cart track 3, the gantry 4 is provided with a trolley track 5 perpendicular to the direction of the cart track 3, the trolley track 5 is provided with a lifting turning trolley 6, and the lifting turning trolley 6. The bottom of the telescopic lifting rod 7 is provided with a rigid telescopic lifting rod 7 facing the ground, and the bottom of the telesc...

Embodiment 2

[0037] As a preferred embodiment of the present invention, such as figure 1 , this embodiment discloses a hydroponics transportation system for segments, including a hydroponics pool 1, a pick-and-place turning mechanism arranged on the hydroponics pool 1, and a running trolley 2 for transporting segments, and also includes information Control Center for the Management Server and Action Management Server;

[0038] The side of the water culture pool 1 is provided with a cart track 3 for the operation of the pick-and-place turning mechanism, a water level monitoring device is arranged in the water culture pool 1, and several areas for placing segments are divided in the water culture pool 1 , each area is provided with a sensor for monitoring whether the segment is placed, and the water level monitoring device and the sensor are connected to the control center by communication;

[0039] The pick-and-place turnover mechanism includes a gantry 4 erected on the cart track 3 at the...

Embodiment 3

[0043] As a preferred embodiment of the present invention, such as figure 1 , this embodiment discloses a hydroponics transportation system for segments, including a hydroponics pool 1, a pick-and-place turning mechanism arranged on the hydroponics pool 1, and a running trolley 2 for transporting segments, and also includes information Control Center for the Management Server and Action Management Server;

[0044] The side of the water culture pool 1 is provided with a cart track 3 for the operation of the pick-and-place turning mechanism, a water level monitoring device is arranged in the water culture pool 1, and several areas for placing segments are divided in the water culture pool 1 , each area is provided with a sensor for monitoring whether the segment is placed, and the water level monitoring device and the sensor are connected to the control center by communication;

[0045] The pick-and-place turnover mechanism includes a gantry 4 erected on the cart track 3 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com