Graphene far infrared electric floor heating packaging assembly line

A packaging line and infrared electricity technology, applied in the field of packaging, can solve the problem of low work efficiency, reduce labor intensity, ensure safety, and improve product packaging efficiency and packaging accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

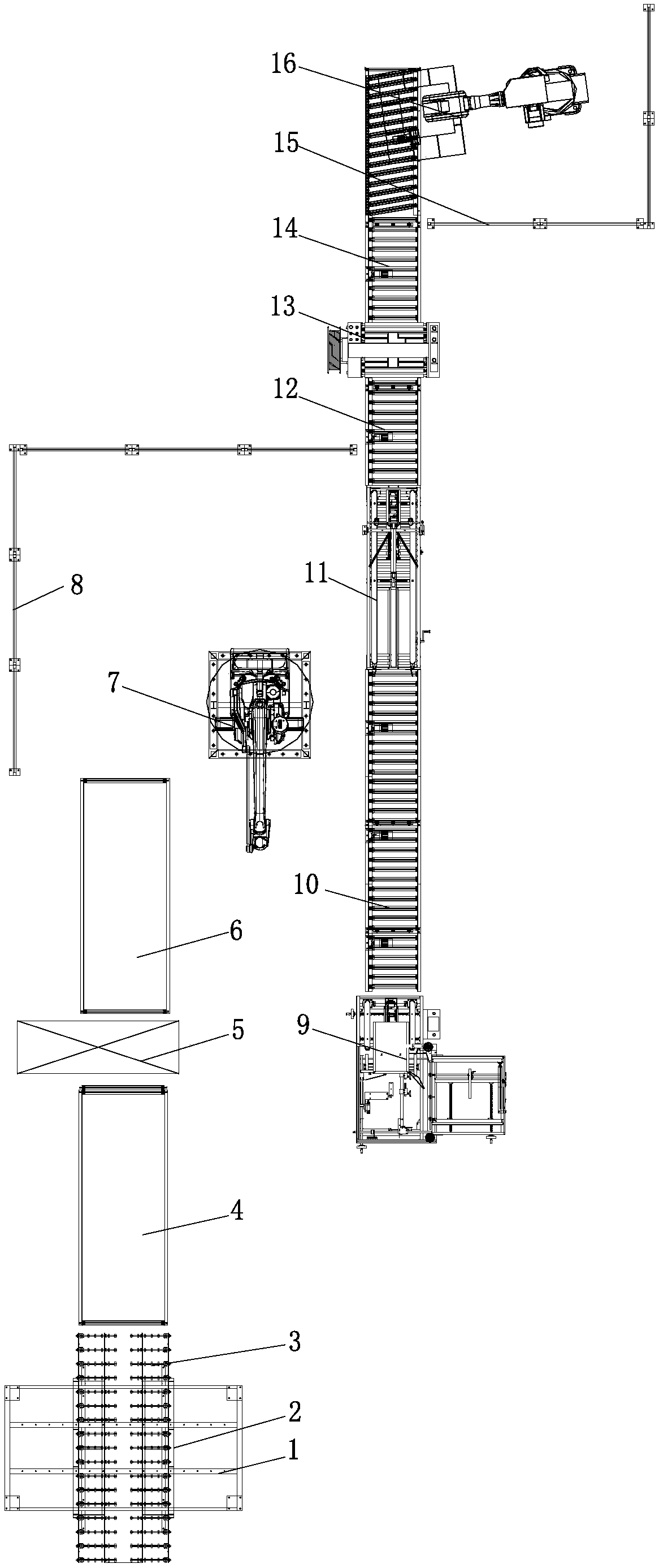

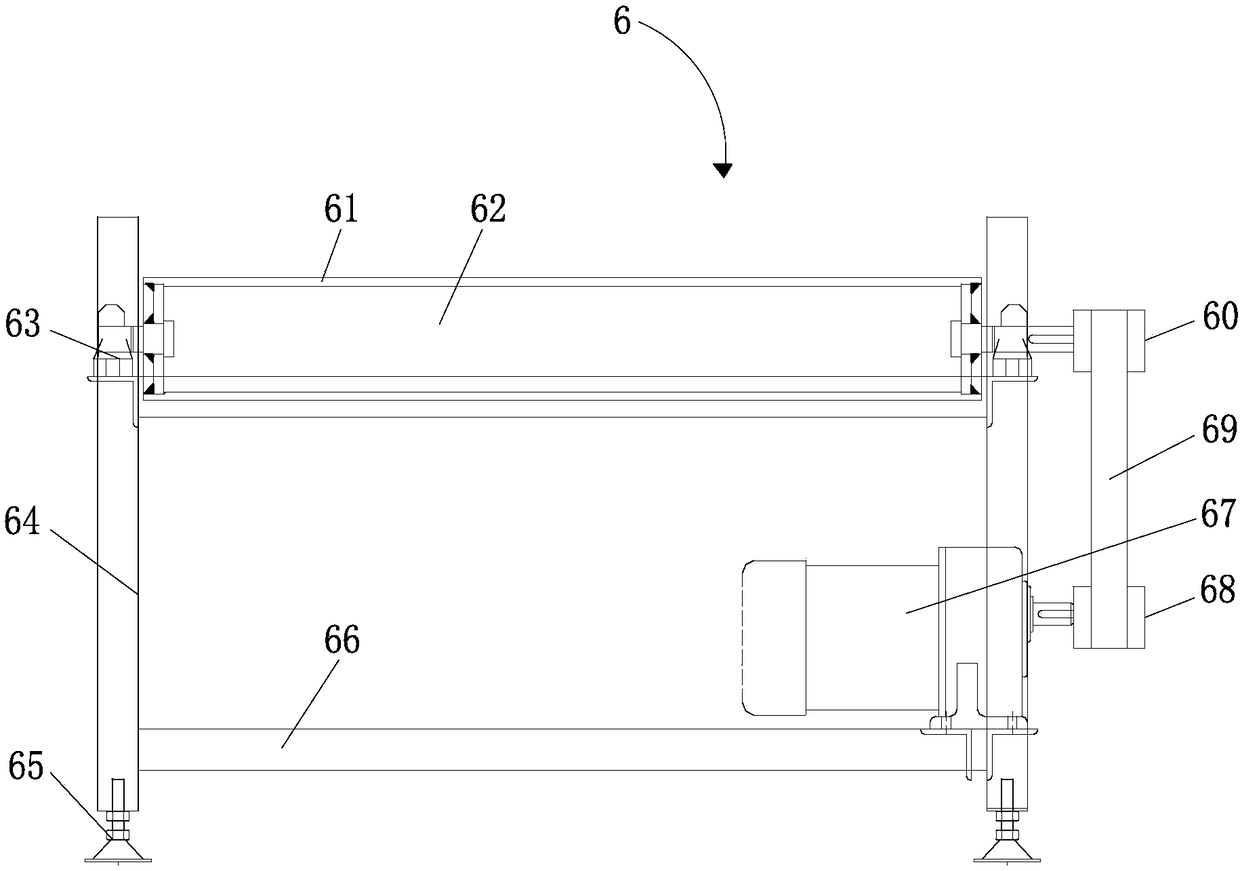

[0017] refer to Figure 1-2 , a graphene far-infrared electric floor heating packaging line, including a roller conveyor line 3 and a first packing reciprocator 10, the roller conveyor line 3 is placed with a processed far-infrared electrothermal film, and the above roller conveyor line 3 An automatic inkjet printer 1 is also provided, and the automatic inkjet printer 1 is set on the ground through a bracket, and a finished product palletizing mechanism 2 is also installed on the ground below the roller conveying line 3, and on the ground on the side of the roller conveying line 3 A slope transmission line 4 is also provided, and one end of the slope transmission lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com