Door machine left slow door slide plate assembly

A technology of door sliding plate and door operator, which is applied to elevators, transportation and packaging in buildings, can solve the problems of inconvenient installation and debugging, high comprehensive cost, hidden safety hazards, etc., and achieves easy processing and manufacturing, low comprehensive cost and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

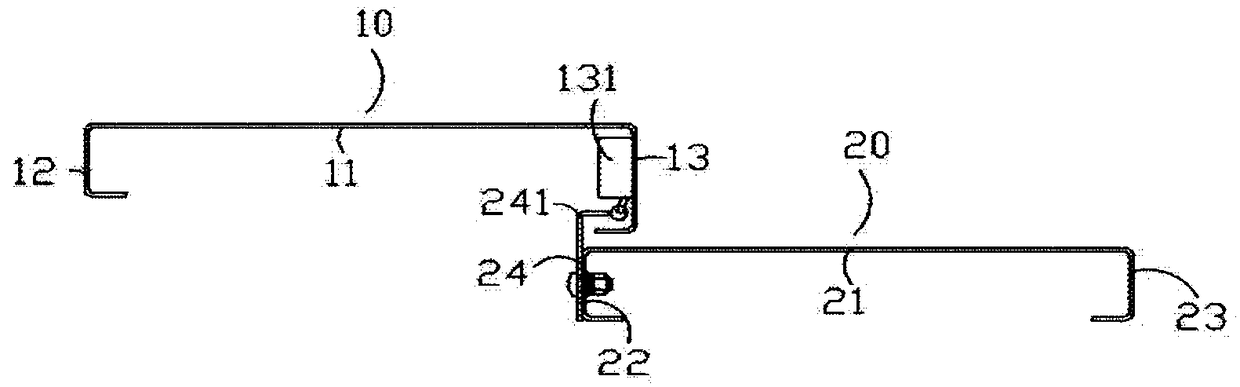

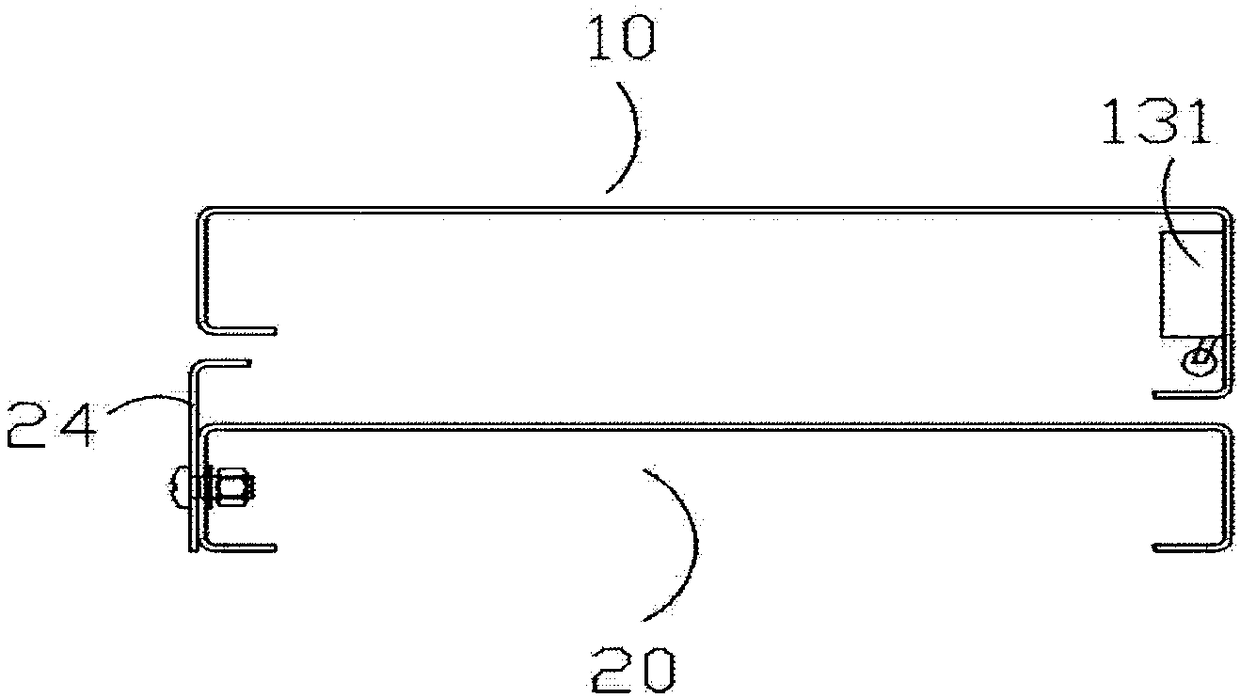

[0028] Such as Figures 1 to 2 As shown, a safety interlocking structure of fast and slow doors of an elevator includes a slow door 10 and a shutter 20. During a specific operation, the slow door 10 and the shutter 20 are synchronously opened or closed in the same direction.

[0029] The slow door 10 includes a door panel 11, a first door panel edging 12 and a second interlocking edging 13, wherein the first door panel edging 12 and the second interlocking edging 13 are fixedly connected to both sides of the door panel 11 . The shutter 20 is arranged outside the slow door 10 , and the shutter 20 is arranged parallel to the slow door 10 .

[0030] The shutter 20 includes a shutter door plate 21, a first shutter edge 22, a second shutter edge 23 and a linkage plate 24, wherein the first shutter edge 22 and the second shutter edge 23 are fixedly connected to the shutter door plate 21 sides. The linkage plate 24 is fixedly connected to the outside of the first shutter surround ...

Embodiment 2

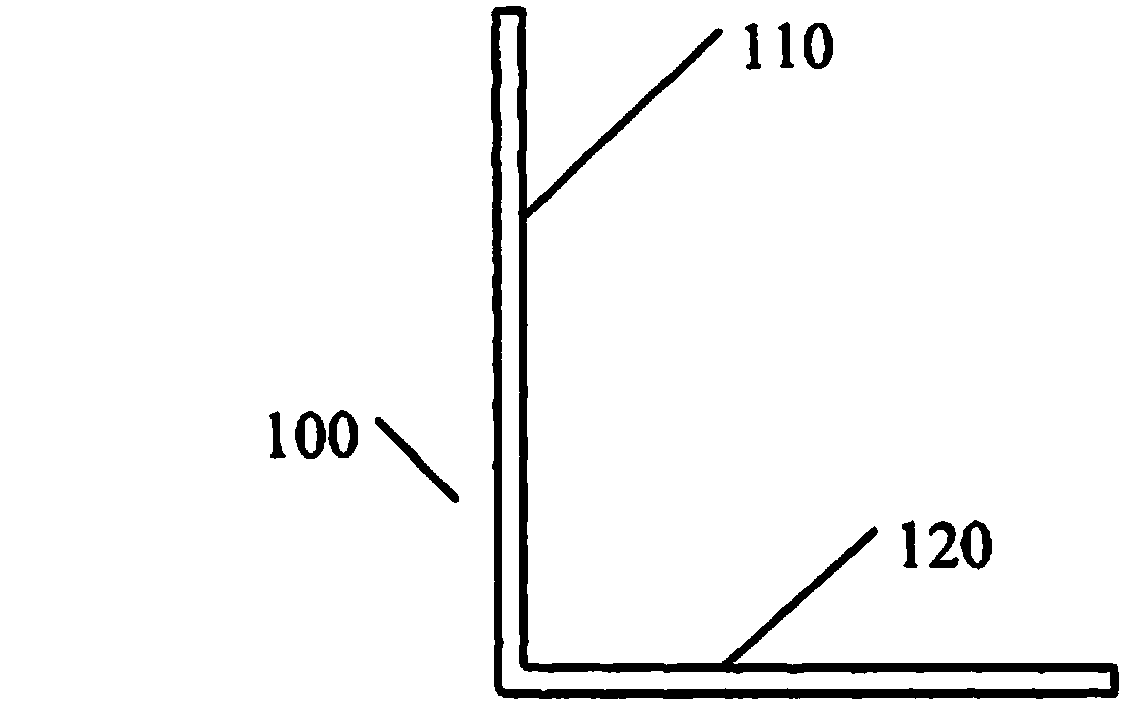

[0036] Such as figure 1 , figure 2 and image 3As shown, the slow door connecting plate of the present application is a plate body 100 bent at 90 degrees. The plate body 100 is made of a steel plate with a thickness of 4mm, a length of 195mm, and a width of 135mm, which is punched by a CNC punching machine and then bent by a folding machine. The board body 100 includes a first board body 110 and a second board body 120, the first board body 110 is at ninety degrees to the second board body 120, and a slow door is arranged on the first board body 110 The swing rod connection hole 101, the second plate body 120 is provided with two slow door connection holes 102, the slow door swing rod connection hole 101 and the slow door connection hole 102 are rectangular holes, the slow door swing The two edges of the rod connecting hole 101 are provided with a semicircular hole integrated with the slow door swing rod connecting hole 101, and the two edges of the two slow door connecting...

Embodiment 3

[0041] The safety system of the elevator platform door of the present invention mainly consists of an extension plate 10, a rack 20, a pinion 30, an operating rod 40, a tension spring 50 and a pushing spring 60 applied to an ordinary elevator, which is installed in the platform. The security system is installed in the elevator door 120 connected to the elevator car door 110, as shown. Figure 6 to Figure 8 Installed on the front of the lift truck 100 and opens and closes left and right.

[0042] The extension plate 10 is extended in height for installation on the upper part of the elevator door 100 and it does not interfere with different parts equipped with it. It is arranged such that a metal plate having a prescribed thickness is bent with a bent portion and the metal plate is fixed to an upper portion of the elevator door 120 by a separate fastening device.

[0043] Power is transmitted to the pinion 30 according to the left and right movement of the elevator door 120 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com