Transmission telegraph pole pull-up preventing structure with reset function

A technology for power transmission poles and poles is applied to the structural field of preventing power transmission poles from being pulled up, which can solve the problems of consuming a lot of manpower and financial resources, high cost, and endangering the safety of power grids, and achieves the effects of increasing weight and increasing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

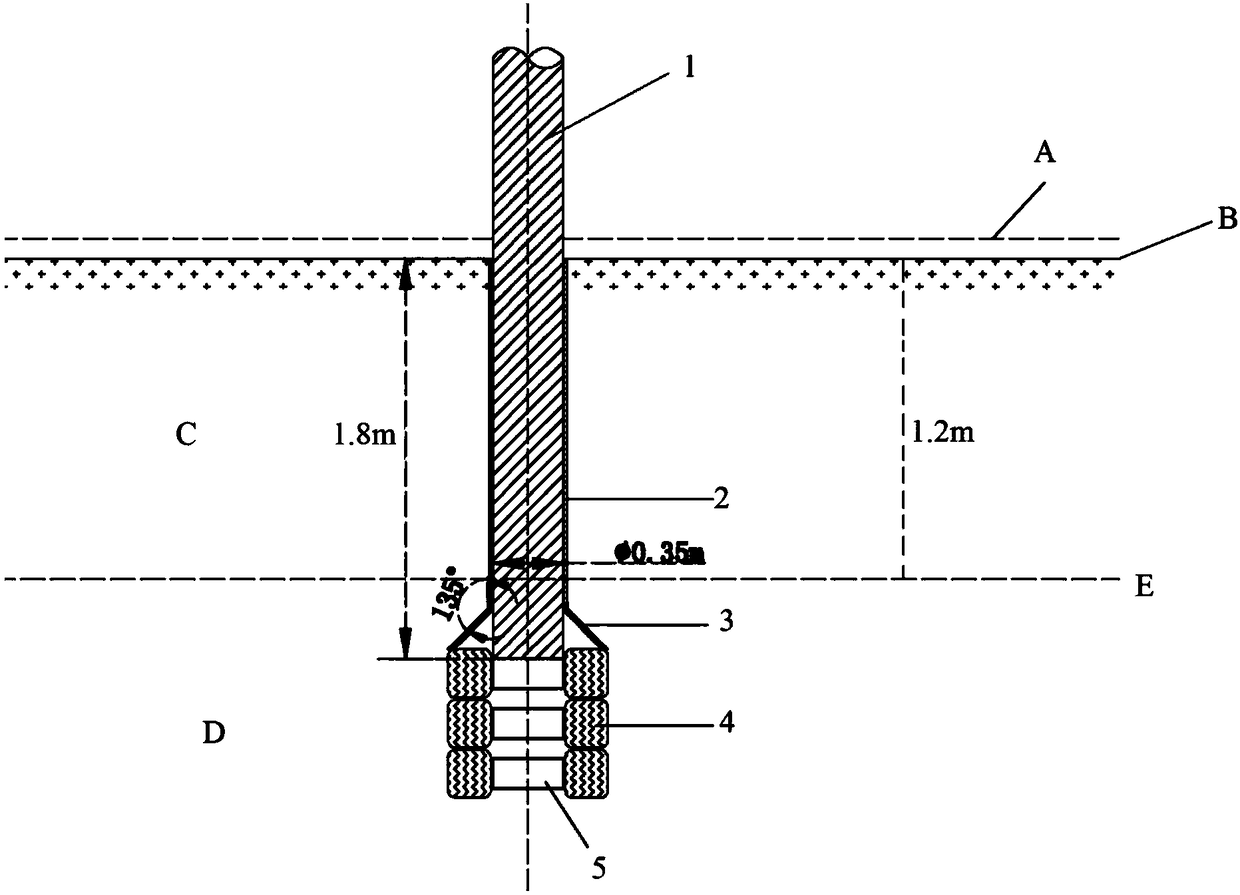

[0036] The burial depth of the utility pole 1 in the present embodiment is 1.8m, wherein the burial depth of the utility pole buried in the permafrost layer C is 0.6m, that is, buried in the permafrost layer above the boundary line E between the permafrost layer and the non-frozen layer The pole depth in C is 1.2m.

[0037] like figure 1As shown, a structure with a reset function to prevent the pull-up of a power transmission pole includes: a pole 1, a drag-reducing layer 2, a ring cover 3, and a reset device. The utility pole 1 is vertically arranged, and the ring cover is Conical, made of stainless steel. The resetting device is made up of a tire 4 and a wheel hub 5, the tire 4 and the wheel hub 5 are co-installed and placed horizontally, the bottom end of the utility pole 1 is welded together with the uppermost hub; 1 are 45°, and are fixedly connected; the other end of the ring cover 3 is fixedly connected with the uppermost wheel hub.

[0038] The drag-reducing layer 2...

Embodiment 2

[0041] The burial depth of the utility pole 1 in the present embodiment is 2.0m, wherein the burial depth of the utility pole buried in the permafrost layer C is 0.4m, that is, buried in the permafrost layer above the boundary E of the permafrost layer and the non-frozen layer The poles in C have a depth of 1.6m.

[0042] A structure with a reset function to prevent pulling up of a power transmission pole, comprising: a pole 1, a drag reducing layer 2, a ring cover 3, and a reset device, the utility pole 1 is vertically arranged, and the ring cover is conical, Made of stainless steel. The resetting device is made up of a tire 4 and a wheel hub 5, the tire 4 and the wheel hub 5 are co-installed and placed horizontally, the bottom end of the utility pole 1 is welded together with the uppermost hub; 1 are 30°, and fixedly connected, the other end of the ring cover 3 is fixedly connected with the uppermost wheel hub.

[0043] The drag reducing layer 2 is arranged on the root sur...

Embodiment 3

[0046] The burial depth of the utility pole 1 in the present embodiment is 2.4m, wherein the burial depth of the utility pole buried in the permafrost layer C is 0.6m, that is, the permafrost layer buried in the permafrost layer and the frozen layer above the boundary line E of the non-frozen layer The pole depth in C is 1.8m.

[0047] A structure with a reset function to prevent pulling up of a power transmission pole, comprising: a pole 1, a drag reducing layer 2, a ring cover 3, and a reset device, the utility pole 1 is vertically arranged, and the ring cover is conical, Made of stainless steel. The resetting device is made up of a tire 4 and a wheel hub 5, the tire 4 and the wheel hub 5 are co-installed and placed horizontally, the bottom end of the utility pole 1 is welded together with the uppermost hub; 1 are 60°, and are fixedly connected; the other end of the ring cover 3 is fixedly connected with the uppermost wheel hub.

[0048] The drag-reducing layer 2 is arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com